- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Tsinfa

-

Year:

-

2024

-

Voltage:

-

380V

-

Weight (T):

-

1 T

-

Model Number:

-

TPS-20

-

Motor Power (kw):

-

2.2 kw

-

Power Source:

-

Hydraulic

-

Nominal Force (kN):

-

200

-

After-sales Service Provided:

-

Online support

-

After Warranty Service:

-

Online support

-

Certification:

-

CE/ISO9001

Quick Details

-

Machine Type:

-

Single Column Hydraulic Press

-

Slide Stroke (mm):

-

300

-

Return Force (kN):

-

100 kN

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Tsinfa

-

Year:

-

2024

-

Voltage:

-

380V

-

Weight (T):

-

1 T

-

Model Number:

-

TPS-20

-

Motor Power (kw):

-

2.2 kw

-

Power Source:

-

Hydraulic

-

Nominal Force (kN):

-

200

-

After-sales Service Provided:

-

Online support

-

After Warranty Service:

-

Online support

-

Certification:

-

CE/ISO9001

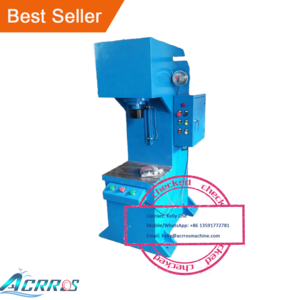

Product Description

Application

TPS Series Hydraulic Press can assemble, disassemble, straightening, calendering, pressing, stretching, bending and punching of machine parts. Each hydraulic press from Tsinfa Cnc equipment combines an industry-leading design with a thick, fully-welded steel plate frame. We build every hydraulic press to provide fine control and to save you time and effort—throughout many years of productivity.

We can customize according to your request, for example, enlarge the workbench, let the worktable move, add two cylinders and so on.

We can customize according to your request, for example, enlarge the workbench, let the worktable move, add two cylinders and so on.

C type Hydraulic Press Machine

This series hydraulic press is suitable for the shaft parts, profile correction techniques, such as shaft, sets of parts and simple installation plate parts tensile, bending, stamping, forming, blanking, etc, can also be general powder, plastic products

* Computer optimized vertical c-type structure design, all-steel welding, post-weld tempering treatment, rigid.

* All parts of the machine are installed in the fuselage, the appearance is neat and beautiful.

* The hydraulic system adopts manual reversing valve, which is convenient for speed regulation.

* Independent power mechanism and electrical system, and use button centralized control, can realize adjustment, manual and semi-automatic three operation modes.

* It can realize two kinds of forming process of constant pressure and fixed process, with the function of rolling delay and adjustable delay time.

* Working pressure, pressing speed, no-load down and deceleration range can be adjusted according to work needs.

Specification

|

Model

|

TPS-16T

|

TPS-20T

|

TPS-40T

|

TPS-60T

|

TPS-100T

|

TPS-160T

|

|

Capacity (kn)

|

160

|

200

|

400

|

600

|

1000

|

1600

|

|

Pressure (MPa)

|

20

|

18

|

22

|

25

|

26

|

25

|

|

Travel ( mm)

|

200

|

200

|

260

|

350

|

500

|

500

|

|

Max. opening height (mm)

|

400

|

400

|

500

|

500

|

800

|

800

|

|

throat depth (mm)

|

150

|

200

|

200

|

250

|

350

|

350

|

|

Table Size ( mm )

|

400*300

|

500*400

|

500*400

|

600*400

|

700*600

|

900*600

|

|

Table height (mm)

|

700

|

700

|

700

|

600

|

700

|

730

|

|

Motor power(Kw)

|

2.2

|

2.2

|

4

|

4

|

5.5

|

7.5

|

|

Weight ( Kg)

|

450

|

650

|

920

|

1400

|

2450

|

3700

|

|

Model

|

TPS-200T

|

TPS-250T

|

TPS-315T

|

TPS-400T

|

TPS-500T

|

TPS-630T

|

|

Capacity (kn)

|

2000

|

2500

|

3150

|

4000

|

5000

|

6300

|

|

Pressure (MPa)

|

25

|

25

|

25

|

26

|

28

|

28

|

|

Travel ( mm)

|

500

|

500

|

500

|

500

|

500

|

600

|

|

Max. opening height (mm)

|

800

|

800

|

800

|

1200

|

1200

|

1200

|

|

throat depth (mm)

|

300

|

400

|

400

|

500

|

500

|

600

|

|

Table Size ( mm )

|

700*570

|

1250*800

|

1250*800

|

1250*900

|

1500*900

|

1200*1200

|

|

Table height (mm)

|

810

|

825

|

864

|

945

|

1000

|

1300

|

|

Motor power(Kw)

|

7.5

|

11

|

15

|

18.5

|

15*2

|

15*2

|

|

Weight ( Kg)

|

4700

|

8500

|

10500

|

15500

|

18500

|

25000

|

Details Images

PROCESSING EXAMPLE

Quality Inspection

Packing & Delivery

Company Profie

Shandong Tsinfa CNC Equipment Co., Ltd specializes in high-end manufacturing and sales of CNC machine tools, machinery and agricultural machinery equipment design and research and development. the company under the jurisdiction of Industrial Park D Area, Tengzhou Shandong province.Our products cover precision CNC cylindrical grinding machines, face cylindrical grinders, CNC lathes, three-axis CNC machining centers, four-axis CNC machining centers, five-axis CNC machining centers, CNC Slotting machines, radial drilling machines, CNC cutting machines, boring machines, and ordinary lathes. Universal milling machine, agricultural mechanization equipment and so on. .

Our mission is to lead in innovation as a machine tool supplier. Supply machine tools with the features of energy-saving,

high-efficient and appropriate. To satisfy requirement for customer and to provide convenience for user, to create value for

society and to seek happiness for employees are our pursuits. Driving customer success and value creation is the key of TSINFA, we stick to giving top priority to the interest of customers by innovation of product’s design and processing technology.

Certifications

FAQ

Q:Your company's delivery time?

A:Universal milling machine is batch production, goods can be sent within 10-50days.

If your order more than 100 sets please contact our support team for confirmation.

Q:Your payment?

A:We usually accpet T/T (30% in advance and 70% before shipment) and L/C at sight.

Q:How do we get the training for the machines?

A:You can send your people to our factory and we will offer traing free of charge.

Q:How about the quality?

A:First we choose best material for the processing.

Being and after processing, we will inspect the finished parts by professional quality inspector.

Q:Your after-sales service?

A:1. Technician available for training and installation at customer’s company

2. 1 Year warrantee. We will sent damage fo the machine parts(non-human factors)for free.

3. Internet service by sending emails and videos, communicating online or calling.

A:Universal milling machine is batch production, goods can be sent within 10-50days.

If your order more than 100 sets please contact our support team for confirmation.

Q:Your payment?

A:We usually accpet T/T (30% in advance and 70% before shipment) and L/C at sight.

Q:How do we get the training for the machines?

A:You can send your people to our factory and we will offer traing free of charge.

Q:How about the quality?

A:First we choose best material for the processing.

Being and after processing, we will inspect the finished parts by professional quality inspector.

Q:Your after-sales service?

A:1. Technician available for training and installation at customer’s company

2. 1 Year warrantee. We will sent damage fo the machine parts(non-human factors)for free.

3. Internet service by sending emails and videos, communicating online or calling.

Hot Searches