- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

Boiler Capacity

-

Weight:

-

Boiler Capacity

-

Product name:

-

Biomass steam generator

-

Steam temperature:

-

170/184/194

-

Design fuel:

-

Biomass

-

Rated working pressure:

-

0.7/1.0/1.25Mpa

-

Application:

-

Steam Generator

-

Manufacturer:

-

Zhongde boiler

-

Quality:

-

High-quality

-

Type of boiler:

-

Steam Boiler

-

Color:

-

Customers Requirment

Quick Details

-

Steam Production:

-

100Kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Zhongde

-

Dimension(L*W*H):

-

Boiler Capacity

-

Weight:

-

Boiler Capacity

-

Product name:

-

Biomass steam generator

-

Steam temperature:

-

170/184/194

-

Design fuel:

-

Biomass

-

Rated working pressure:

-

0.7/1.0/1.25Mpa

-

Application:

-

Steam Generator

-

Manufacturer:

-

Zhongde boiler

-

Quality:

-

High-quality

-

Type of boiler:

-

Steam Boiler

-

Color:

-

Customers Requirment

Product Description

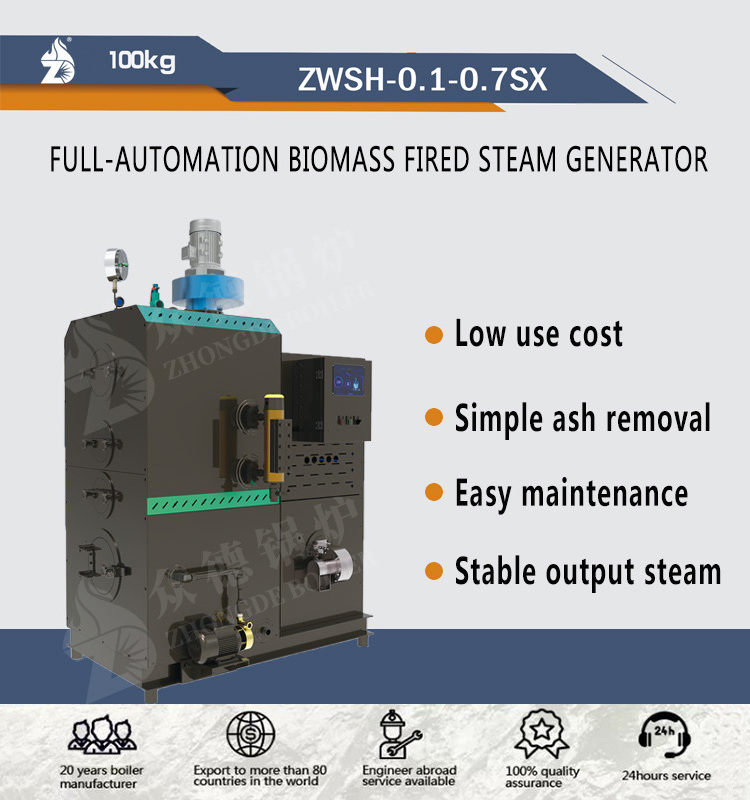

Full automatic special steam generator for biomass particles, integrated cyclone combustion in the whole furnace, stable steam output, convenient and simple ash removal, no dead corner, and no ash blockage in ten years.

Product Show

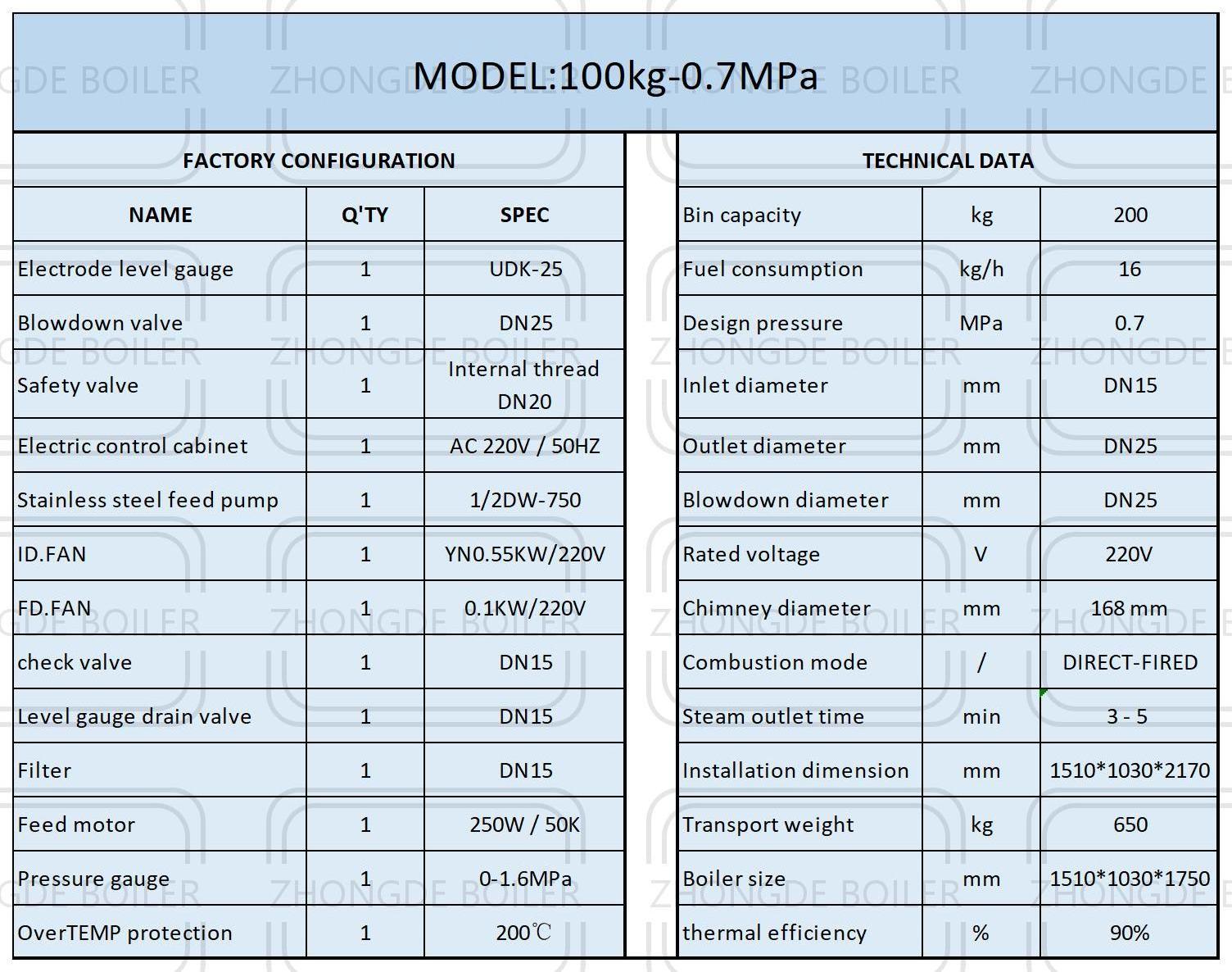

Product specification

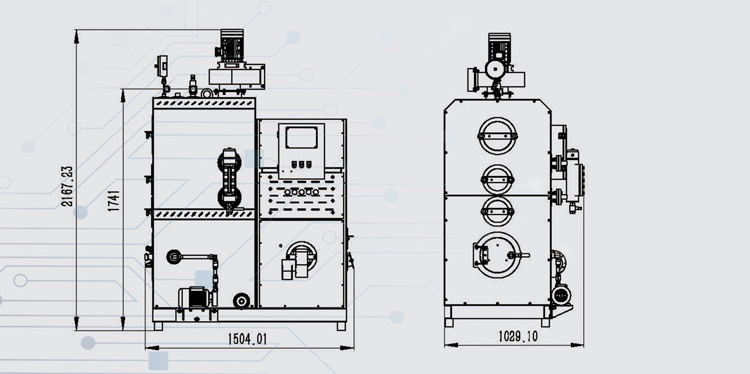

Product size

Packing and shipping

1. The boiler main unit and the large auxiliary equipment are naked, and other precision instruments or small auxiliary equipment are packed in wooden boxes.

2. According to the tonnage of the boiler,we use 20-foot cabinet,40-foot cabinet,20 frame or 40 frame box for shipment.

3. All goods will be professionally reinforced after being loaded into the container.

Our Survice

Pre-sale service:

1.Provide the most suitable and cost-effective boiler solution according to different requirements of various industry. 2.Provide drawings for building your boiler room,such as foundation drawing, layout drawing, boiler room layout, etc.

On-sale service:

24 hours online and keep close contacts during the production process to ensure on time delivery with perfect finished product. We send pictures and videos to let customers know the production schedule.

After-sales service:

1.provide full range of original spare parts.

2.Provide engineers abroad installation and commissioning service.

3.Held online or site training for boiler workers to ensure the safe operation.

4.Free maintenance and repair for one year and lifelong service.

1.Provide the most suitable and cost-effective boiler solution according to different requirements of various industry. 2.Provide drawings for building your boiler room,such as foundation drawing, layout drawing, boiler room layout, etc.

On-sale service:

24 hours online and keep close contacts during the production process to ensure on time delivery with perfect finished product. We send pictures and videos to let customers know the production schedule.

After-sales service:

1.provide full range of original spare parts.

2.Provide engineers abroad installation and commissioning service.

3.Held online or site training for boiler workers to ensure the safe operation.

4.Free maintenance and repair for one year and lifelong service.

Hot Searches