- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

6000mm*1500mm*2000mm

-

Capacity:

-

3

-

Weight:

-

2050

-

Name:

-

MOSEN

-

Application:

-

rubber,rubber tuber,rubber roller,etc

-

Product name:

-

Large Horizontal Pressure Vessel Autoclave

-

Material:

-

Q345R

-

Design pressure(Mpa):

-

0.85MPA

-

Design temperature:

-

180C

-

Color:

-

BLUE

-

Certification:

-

ASME,ISO

-

Advantage:

-

Welding

Quick Details

-

Max Working Pressure(MPa):

-

0.85 MPa

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

MOSEN

-

Dimension(L*W*H):

-

6000mm*1500mm*2000mm

-

Capacity:

-

3

-

Weight:

-

2050

-

Name:

-

MOSEN

-

Application:

-

rubber,rubber tuber,rubber roller,etc

-

Product name:

-

Large Horizontal Pressure Vessel Autoclave

-

Material:

-

Q345R

-

Design pressure(Mpa):

-

0.85MPA

-

Design temperature:

-

180C

-

Color:

-

BLUE

-

Certification:

-

ASME,ISO

-

Advantage:

-

Welding

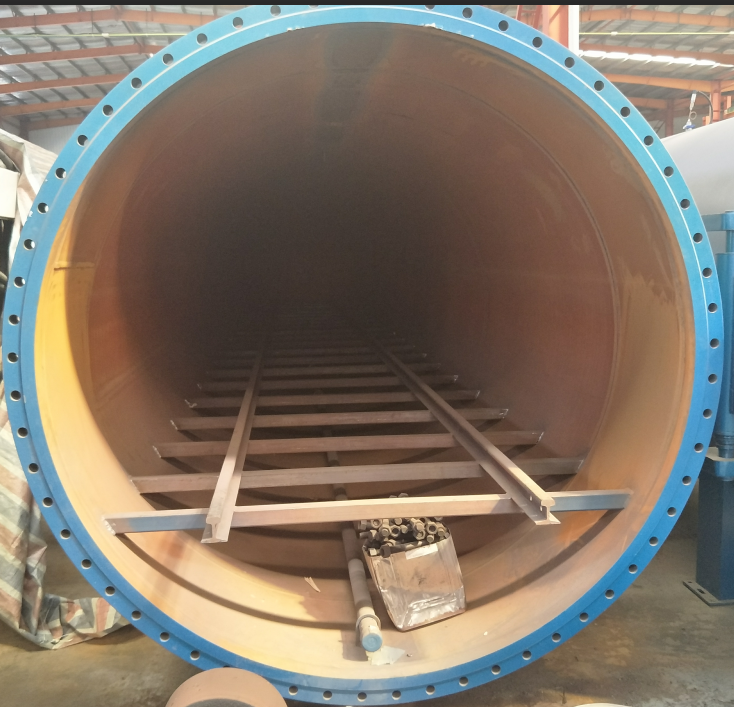

Large Horizontal Pressure Vessel Autoclave

The steam enters from the bottom of the tank, and two steam inlets are arranged in the middle of the tank, and the air inlet is automatically controlled by a pneumatic angle seat valve. The steam diffusion tube is arranged at the bottom of the tank. The small holes (4mm, 5mm, 6mm) in the diffuser are arranged in a certain order and inclined angle to ensure that the temperature spreads evenly around the tank after the steam enters the tank, preventing uneven diffusion of steam. The product caused by direct steam heating is unevenly heated, and the temperature inside the vulcanization tank is uniform without dead angle. After setting the working program, the control system automatically performs the functions of intake, exhaust, temperature rise, heat preservation, vulcanization, etc. After the vulcanization is finished, it automatically closes and gives an audible and visual alarm sound. The temperature and pressure in the vulcanization tank are kept constant and uniform, which solves the problem that the quality of the products in the tank is different due to uneven temperature and pressure.

Main Features

Heating Type: Electric Steam Rubber Autoclave

Opening door type: Manual quick opening, single man can easily complete all the steps. This design is the most advanced way and idea of opening the door. Open and close the door normally when it is power failure.

Sealing Method:The door uses inflatable silicone sealing ring, which is simple and convenient to maintain and the sealing effect is obviously better than other methods with more than 2 years of service life.

Safety chain type: 3 sets of safety interlock devices are designed at the tank door. It solves the safety problems caused by mistaken operation completely.

(2) Pressure automatic safety chain (2) Manual safety chain (3) Sealing ring safety chain

Control Type: PLC Computer Full-automatic Control, Computer Semi-automatic Control and Manual Control

Insulation Type: It uses double layer external insulation, saving thirty percent of energy consumption than ordinary insulation.

Loading mode: There are two 36# steel rail with the national standard in the tank. A filtering net is covered in the discharge hole which is easy to clean the sundries without clogging the outlet

Product Parameter

| Brand Name | MOSEN |

| Design Temperature | 180C |

| Design Pressure | 0.85MPA |

| Material | Q345R |

| Diameter | 900mm |

| Length | 5200mm |

| Thickness | 10mm |

Product Advantage

1. The vulcanization autoclave produced by our company is automatically controlled by temperature, pressure and time, which is 20% more energy efficient than the vulcanization tank products under the same specifications of other manufacturers.

2. All the vulcanized tanks are made of Q345R plates for pressure vessels, which fully guarantee the safety and stability of the products.

3. Our company continuously carries out innovations in vulcanization tanks based on years of production experience and user feedback.

4, special high temperature and high pressure integrated fan, to ensure uniform temperature inside the tank without dead angle, thus ensuring product quality and stability.

5. The special stainless steel electric heating tube assembly is a new type of thermal insulation and anti-oxidation material, which has fast heating and long service life.

6. The temperature inside the vulcanization autoclave is fast, the temperature is uniform, and the pressure is constant. The whole process is automated, and there is a clear tone after the work is completed.

7. The vulcanization autoclave adopts external insulation to ensure the internal temperature difference is about +3, which saves 30% energy consumption compared with the ordinary tank.

8. Vulcanization autoclave sealing method The company adopts inflatable silicone rubber sealing ring, which is better than ordinary one and has a longer service life.

9. This equipment belongs to the category of non-standard pressure vessels. Heating parameters, working medium, working pressure, working temperature, external dimensions and many other parameters support private ordering.

Application

Widely used in vulcanization of rubber products, SBR thermoplastic as well as the carbonization and degreasing of bamboo, such as, rubber, cable, printing and dyeing, chemical, building materials and other industries. Mainly used in rubber products, rubber hose, rubber roller etc.

Used in tire, rubber sleeve cable, rubber shoes, rubber hose, rubber roller, rubber belt, belt, conveyor belt, rubber ball, rubber lining, rubber cloth, rubber head, gloves, red flag, etc.

Wood drying, wood preservative, wood fire prevention, wood impregnation, wood color, wood cooking, bamboo carbonization, wood modification, wood optimization, wood fire retardant

Also used for Yarn thread, mane, socks heat setting, high pressure modification and degreasing of horn and bone, feather hydrolysis, oxidation treatment of aluminum products, steaming and cooking of carbon materials, asbestos friction materials, gypsum and its products.

Customer Visiting