- Product Details

- {{item.text}}

Quick Details

-

Color:

-

RAL7035

-

Function:

-

remove particulates from liquids

-

Capacity:

-

5-200M3/h

-

Application:

-

Water Purification

-

Voltage:

-

380V /Customized

-

Usage:

-

Automatic Operation

-

Advantage:

-

Efficient and stable

-

Packing:

-

Standard Package

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Product name:

-

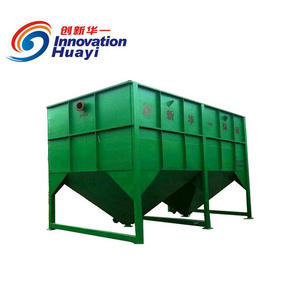

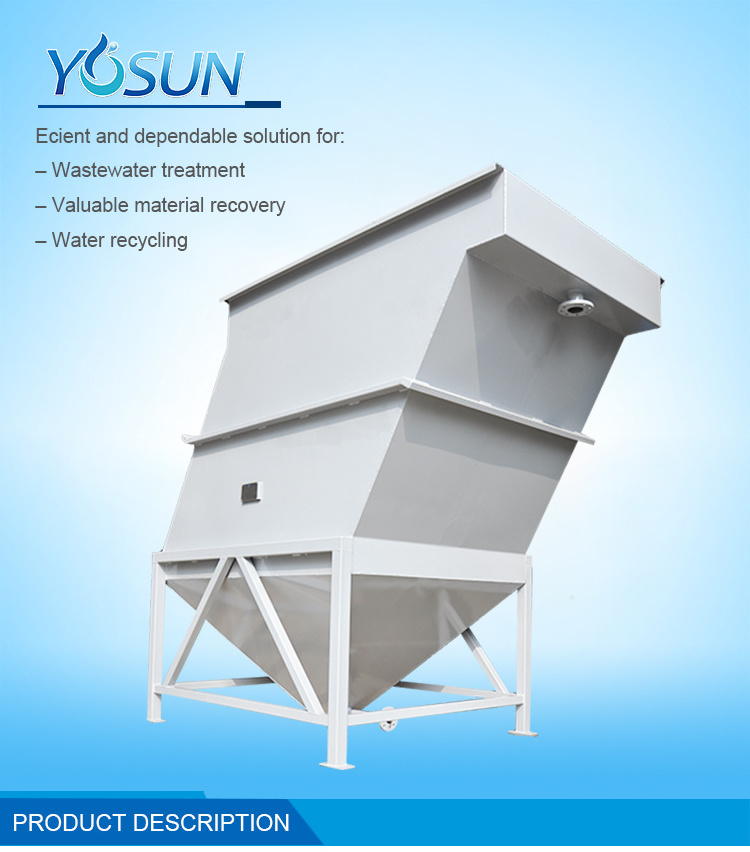

lamellar clarifier wasterwater treatment

-

Model:

-

LST-I &LST-II

-

Color:

-

RAL7035

-

Function:

-

remove particulates from liquids

-

Capacity:

-

5-200M3/h

-

Application:

-

Water Purification

-

Voltage:

-

380V /Customized

-

Usage:

-

Automatic Operation

-

Advantage:

-

Efficient and stable

-

Packing:

-

Standard Package

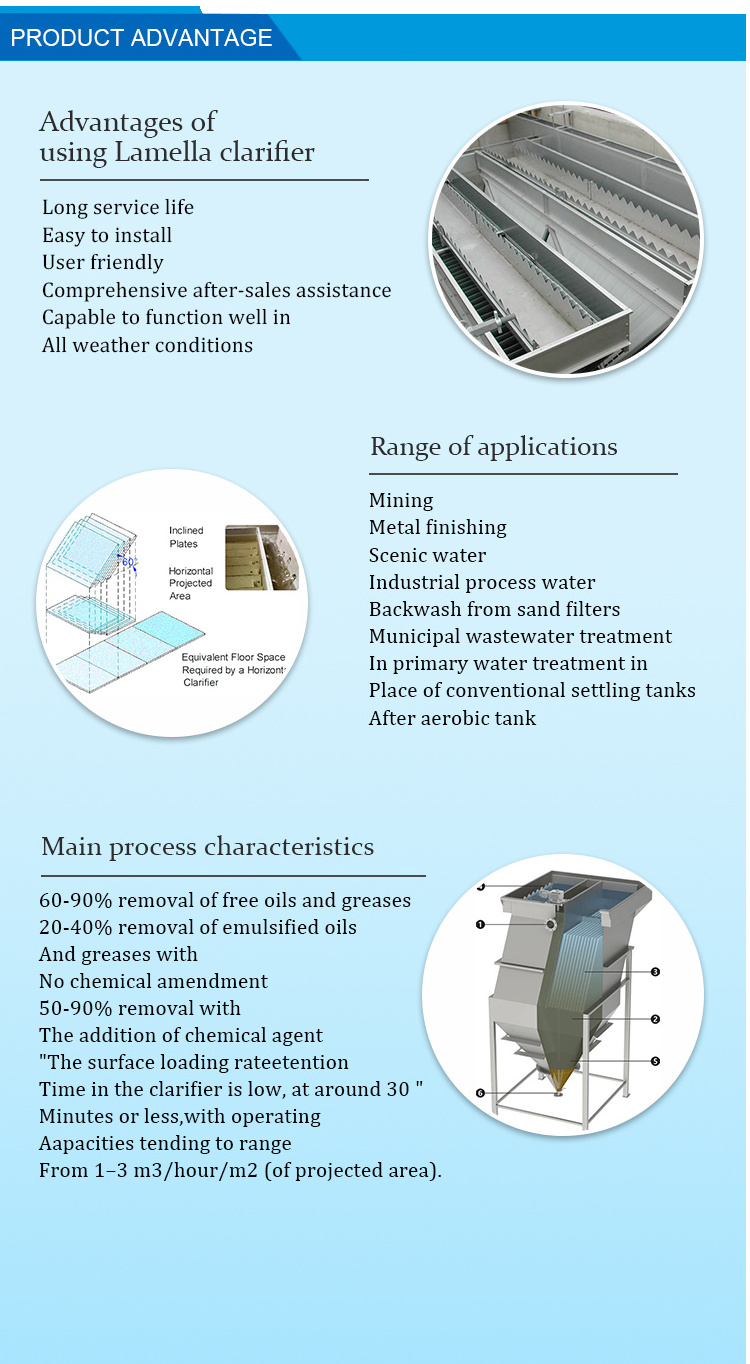

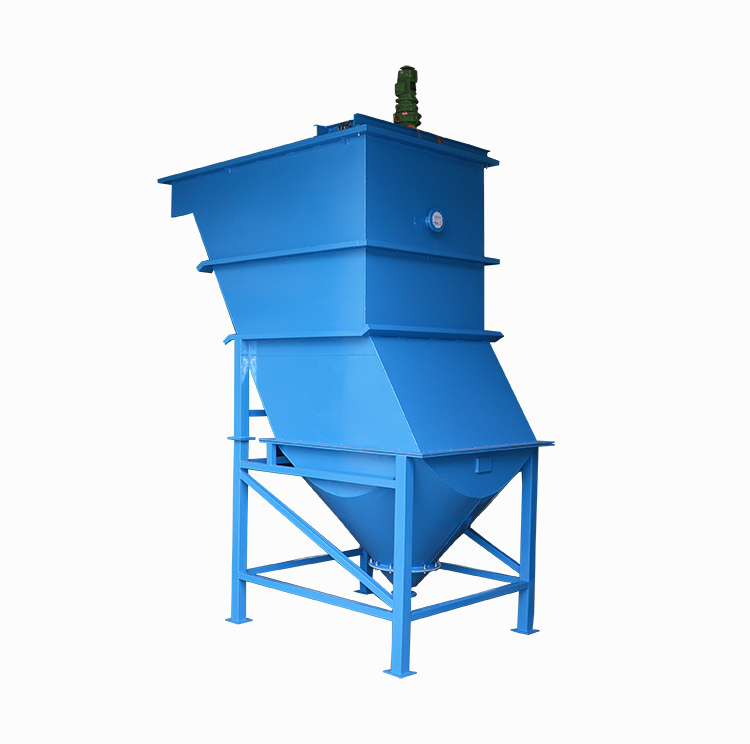

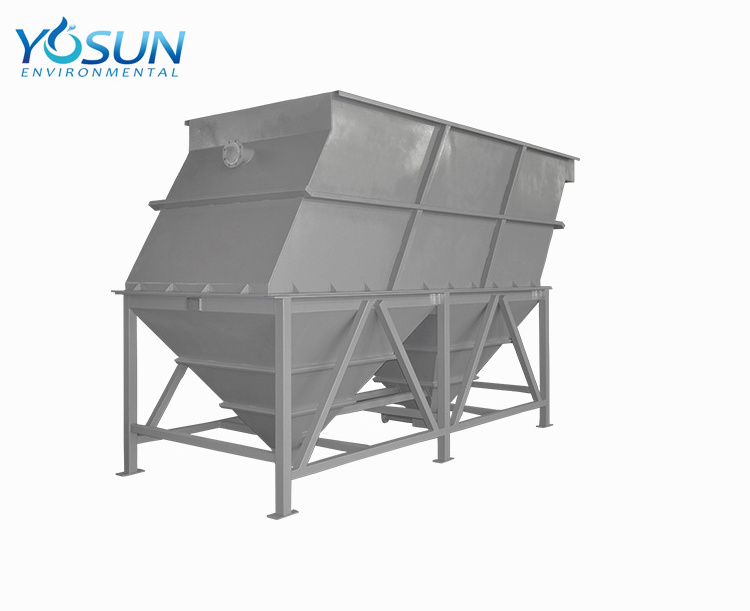

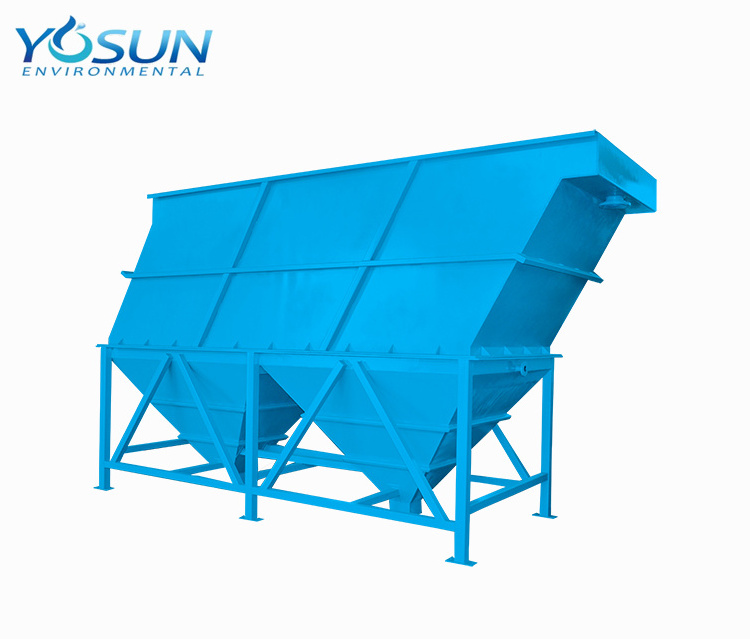

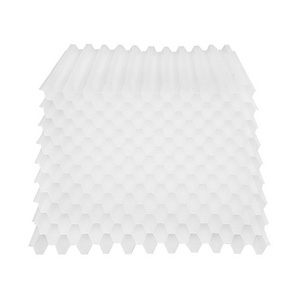

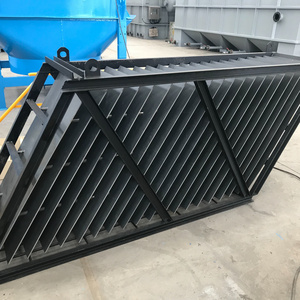

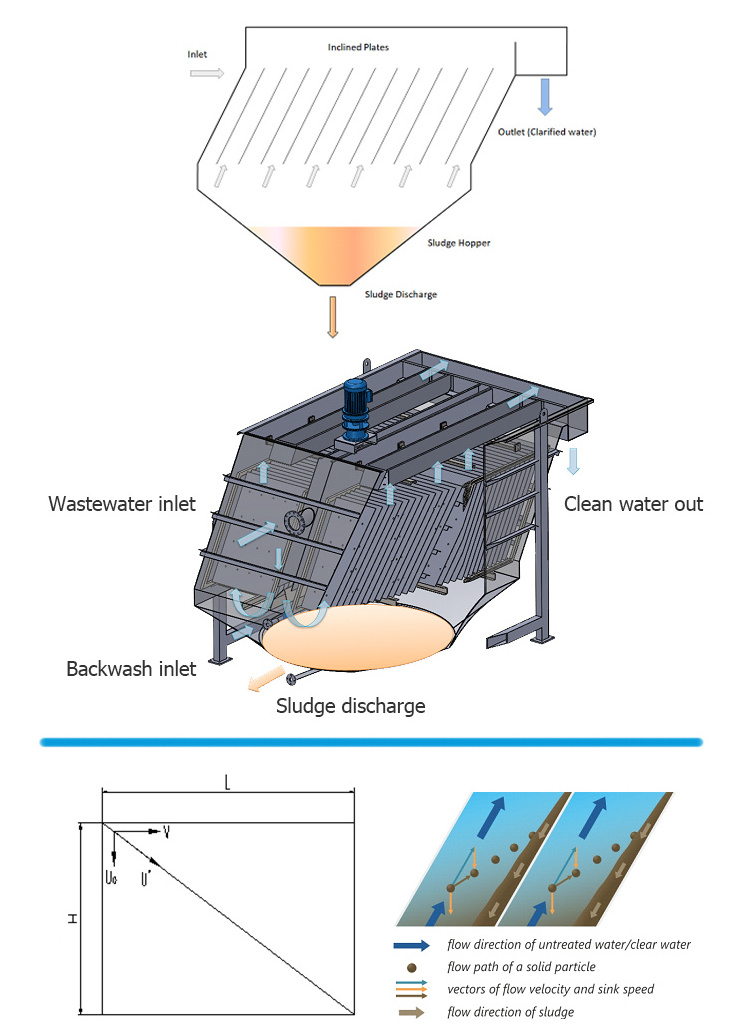

Typical lamella clarifier design consists of a series of inclined plates framework components, see first figure. The untreated feed (raw)water stream enters from the top of body side and flows down a feed channel underneath the inclined plates. Water then flows up inside the clarifier between the inclined plates. During this time solids settle onto the plates and eventually fall to the bottom of the vessel,The route a particle takes will be dependent upon the flow rate of the suspension and the settling rate of the particle and can be seen in the second figure.At the bottom of the vessel a hopper or funnel collects these particles as sludge. Sludge may be continuously or intermittently discharged.Above the inclined plates all particles have settled and clarified water is produced which is drawn off into an outlet channel. The clarified water exits .

|

LST

Model |

Capacities

(m 3 /h) |

Piping Connections() | Dimensions(m) | Special Requirements | ||||||

| Inlet(a) | Effluent(b) | Sludge(c) | Backwash(d) | L | W | H | Standard of the flange | Voltage standard | ||

| LST- | 5 | 80 | 80 | 50 | 50 | 2.55 | 1.6 | 2.9 |

when making an inquiry |

|

|

LST- |

10 | 100 | 100 | 50 | 50 | 3.35 | 1.82 | 3 | ||

| LST- | 15 | 100 | 100 | 50 | 50 | 3.35 | 2.02 | 3 | ||

| LST- | 20 | 100 | 100 | 50 | 50 | 3.35 | 2.02 | 3 | ||

| LST- | 30 | 150 | 150 | 50 | 50 | 4.2 | 2.22 | 3 | ||

| LST- | 40 | 150 | 150 | 50 | 50 | 4 | 2.8 | 3 | ||

| LST- | 50 | 200 | 200 | 50 | 50 | 4.65 | 2.82 | 3 | ||

| LST- | 60 | 200 | 200 | 50 | 50 | 4.7 | 3 | 3 | ||

| LST- | 70 | 250 | 200 | 50 | 50 | 6.4 | 2.6 | 3 | ||

| LST- | 80 | 250 | 200 | 50 | 50 | 6.8 | 2.82 | 3 | ||

| LST- | 100 | 250 | 250 | 50 | 50 | 7.05 | 3.02 | 3 | ||