- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Dimensions:

-

3500*700*1400MM

-

Rated Duty Cycle:

-

100%

-

Rated Capacity:

-

24kw

-

Current:

-

50/60HZ

-

Weight (KG):

-

450 KG

-

Number of heating zones:

-

Up 6 Down6

-

Heating zone length:

-

2100mm

-

Heat way:

-

Hot air

-

Number of cooling zones:

-

2

-

Mesh belt width:

-

350mm

-

Transportation direction:

-

left to right

-

Conveyor belt height:

-

880±20mm

-

Delivery method:

-

Mesh belt drive + guide rail

-

power supply:

-

5-wire 3-phase 380V 50/60Hz

-

Heating time:

-

About 20 minutes

-

Certification:

-

CE

Quick Details

-

Place of Origin:

-

Beijing, China

-

Brand Name:

-

Huaweiguochuang

-

Use:

-

PCB Soldering

-

Voltage:

-

380V

-

Dimensions:

-

3500*700*1400MM

-

Rated Duty Cycle:

-

100%

-

Rated Capacity:

-

24kw

-

Current:

-

50/60HZ

-

Weight (KG):

-

450 KG

-

Number of heating zones:

-

Up 6 Down6

-

Heating zone length:

-

2100mm

-

Heat way:

-

Hot air

-

Number of cooling zones:

-

2

-

Mesh belt width:

-

350mm

-

Transportation direction:

-

left to right

-

Conveyor belt height:

-

880±20mm

-

Delivery method:

-

Mesh belt drive + guide rail

-

power supply:

-

5-wire 3-phase 380V 50/60Hz

-

Heating time:

-

About 20 minutes

-

Certification:

-

CE

Product Description

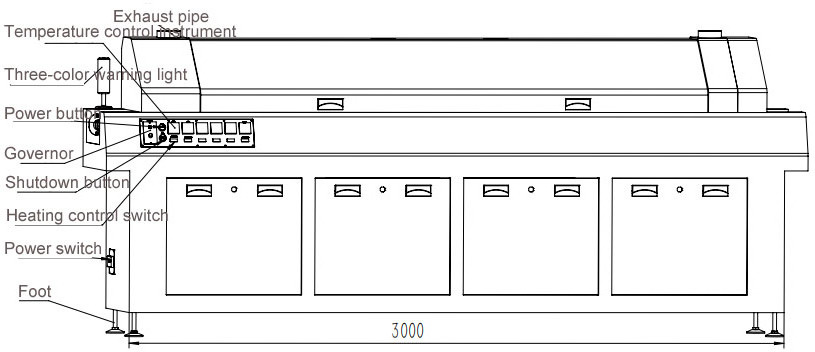

Specification

|

Heating parameters

|

|

|

Number of heating zones

|

Up 6 Down6

|

|

Heating zone length

|

2100mm

|

|

Heat way

|

Hot air

|

|

Number of cooling zones

|

2

|

|

Send part parameters

|

|

|

Mesh belt width

|

350mm

|

|

Transportation direction

|

left→right

|

|

Conveyor belt height

|

880±20mm

|

|

Delivery method

|

Mesh belt drive + guide rail

|

|

Conveyor speed

|

0-600mm/min

Electronic speed regulation

|

|

Control part parameters

|

|

|

Power supply

|

5-wire 3-phase 380V

50/60Hz

|

|

Starting power

|

24KW

|

|

Power during normal operation

|

Approx.6KW

|

|

Heating time

|

About 20 minutes

|

|

Temperature control range

|

Room temperature-400℃

|

|

Temperature control method

|

Full computer PID closed loop control, SSR drive

|

|

Temperature control accuracy

|

±1-2℃

|

|

PCB temperature distribution deviation

|

±2-3℃

|

|

Abnormal alarm

|

Abnormal temperature (super high temperature after constant temperature)

|

|

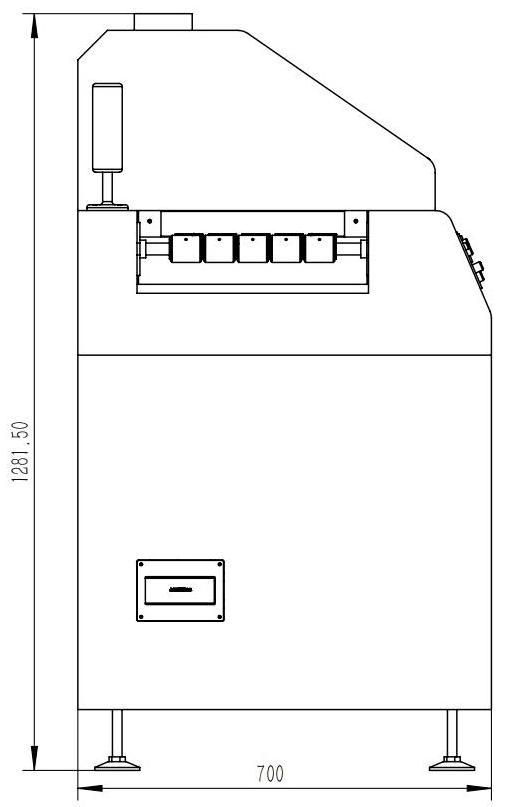

Machine parameters

|

|

|

Size

|

L3500×W700×H1400MM

|

|

Weight

|

Approx.450Kg

|

Introduction to internal structure

Unique advanced long-life heating system

1. The heating system adopts high-efficiency and energy-saving Swedish nickel soldering heating wire, coupled with a curved reflector, which has high thermal efficiency and fast temperature rise speed. A special forced hot air circulation structure system makes the PCB and components heated evenly.

2. The heat preservation system adopts a special high temperature resistant protection system (U.S. Cyril 120kg / cubic high-density heat preservation rock wool), the furnace is made of special stainless steel, suitable for lead-free welding, and the welding area is equipped with a rosin flux recovery system to protect the environment;

3. Adopt Taiwan Mitsukoshi long-axis high-temperature wind-driven motor and ring-shaped heating wire design, module design, no noise, no vibration, easy maintenance and disassembly;

4. The upper and lower sides of the furnace body are uniformly distributed by porous aluminum plates to ensure that the heat reaches the PCB evenly and balanced. The upper furnace body can be opened as a whole to facilitate the cleaning of the furnace chamber.

Reliable and stable transmission system

1. The transmission system adopts Taiwan STK speed regulating motor, matched with 1:150 turbine reducer, with stable operation and stepless adjustable speed of 0-600MM / min.

2. It adopts independent roller structure and flat support, combined with matching stainless steel mesh belt, which can run stably with speed accuracy of ± 20 mm / min;

3. Special stainless steel zigzag mesh belt, durable and wear-resistant, not easy to change after long-term use.

Stable and reliable electrical control system

1. The temperature control adopts Transmit G8 precision controller with fuzzy control and PID intelligent calculation. Through PID intelligent calculation, it automatically controls the heat generation. The fuzzy control function adds overshoot and suppression functions and quickly responds to external heat changes. The fastest speed Respond to changes in external heat and ensure temperature balance through internal control;

2. Each temperature zone adopts Taiwan Vydyne thermocouple to quickly and sensitively respond to changes in each temperature zone, timely transmit and control, and compensate the temperature balance of each temperature zone;

3. The special SSR solid state relay cooperates with the special radiator, the heat dissipation efficiency is greatly improved, and the service life is effectively extended; non-contact output, safe and reliable, combined with the unique fuzzy control function of the thermostat, has been monitoring the external temperature and heat value The change of the temperature is controlled by the minimum pulse to quickly respond to ensure high temperature control accuracy, uniform temperature distribution in the machine, and temperature distribution in the length direction in accordance with IPC standards;

4. Abundant power, rapid temperature rise, about 20 minutes from room temperature to constant temperature;

5. With over temperature tolerance, fault diagnosis, sound and light alarm;

6. Delayed shutdown protection function, evenly cool down after

Hot Searches