- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

1800

-

Motor Power (kW):

-

25.5

-

Item:

-

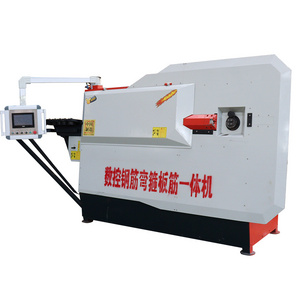

Automatic Steel Rebar Stirrup Bending and Cutting Machine

-

Applied Rebar Dia.:

-

4-12mm ribbed bar

-

Motor Power:

-

18kw+7.5kw

-

Function:

-

Steel wire bending machine

-

Voltage:

-

380V/415V/customized

-

Straightening Speed:

-

0-85m/min

-

Control system:

-

PLC

-

Standard Configuration:

-

8m rebar rack

-

Weight:

-

2550kg

-

Keyword:

-

CNC Steel Rebar Stirrup Wire Bending Machine

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

KAIRUIEN

-

Year:

-

2023

-

Weight (KG):

-

1800

-

Motor Power (kW):

-

25.5

-

Item:

-

Automatic Steel Rebar Stirrup Bending and Cutting Machine

-

Applied Rebar Dia.:

-

4-12mm ribbed bar

-

Motor Power:

-

18kw+7.5kw

-

Function:

-

Steel wire bending machine

-

Voltage:

-

380V/415V/customized

-

Straightening Speed:

-

0-85m/min

-

Control system:

-

PLC

-

Standard Configuration:

-

8m rebar rack

-

Weight:

-

2550kg

-

Keyword:

-

CNC Steel Rebar Stirrup Wire Bending Machine

Product Description

Automatic Electric Cnc Steel Rod Bar Bender 12mm Reinforcing Rebar Stirrup Bending Machine Price

Feature of

Automatic Electric Cnc Steel Rod Bar Bender 12mm Reinforcing Rebar Stirrup Bending Machine Price

1.Automatic wire feeding system(CNC).

2.Moveable air compressor design, to ensure better cooling effect

3.Split, multi-blade design (patented) to reduce consumption costs

4.Large storage capacity can save 500 processing geometric graphics, high degree automation

5.Automatic double wire intake system, high processing efficiency

6. High power feeding motor to ensure bending bar accuracy.

7.The intelligent fault identification alarm system maintenance more convenient

8. Aerodynamic design observation door, easy to adjust and maintain, and much safeand faster.

9.Heavy-duty design line planes, equipped with a brake and buffer device can prevent chaotic lines caused by downtime

10. High quality special material and high treatment to make straightening wheels, traction wheels, the metering wheel, longer life with lower operating costs

1.Automatic wire feeding system(CNC).

2.Moveable air compressor design, to ensure better cooling effect

3.Split, multi-blade design (patented) to reduce consumption costs

4.Large storage capacity can save 500 processing geometric graphics, high degree automation

5.Automatic double wire intake system, high processing efficiency

6. High power feeding motor to ensure bending bar accuracy.

7.The intelligent fault identification alarm system maintenance more convenient

8. Aerodynamic design observation door, easy to adjust and maintain, and much safeand faster.

9.Heavy-duty design line planes, equipped with a brake and buffer device can prevent chaotic lines caused by downtime

10. High quality special material and high treatment to make straightening wheels, traction wheels, the metering wheel, longer life with lower operating costs

11.Touch-screen console, easy to operate, and more fast

12..Control systems: SIEMENS, MITSUBISHI, and YASKAWA SCHNEIDER

12..Control systems: SIEMENS, MITSUBISHI, and YASKAWA SCHNEIDER

4-10mm CNC Rebar Bender

Advantage

1.Computer control, automatically calculates.

2.Automatically adjusts the straightness and automatically cuts off.

1.Computer control, automatically calculates.

2.Automatically adjusts the straightness and automatically cuts off.

3.Applicable to hot/cold rolled steel, low carbon steel steel copper wire.

4.High power national standard motor, with hydraulic ststem, ensure the high efficiency.

Details Images

A full set CNC Bender with

uncoiling rack,receiving rack

Specification

|

Model No.

|

GF-10

|

GF-12

|

GF-12 3D Type

|

|

Rebar Diameter

|

Single Wire Φ4-10mm / Double Wire Φ4-8mm

|

Single Wire Φ4-12mm / Double Wire Φ4-10mm

|

Single Wire Φ4-12mm / Double Wire Φ4-10mm

(Only Single wire for 3D graphics))

|

|

Feeding Speed

|

85m/min

|

85m/min

|

85m/min

|

|

Stirrup Bending Speed

|

1800pcs/h

|

1800pcs/h

|

Hoop bending speed: single line 13pcs/min, double line 26pcs/min

|

|

Total Power

|

Servo 11kw+7.5kw,

cutting motor 4kw,

air compressor motor4kw

|

Servo 18kw+7.5kw, cutting motor 4kw,

air compressor motor 4KW

|

Servo 18kw+7.5kw, cutting motor 4kw, air compressor motor

|

|

Rated Power

|

380V or customized

|

380V or customized

|

380V or customized

|

|

Weight

|

1800KG

|

1800KG

|

2550kg

|

|

Dimension

|

3300*1000*1700mm

|

4160*1160*2130mm

|

3500*1000*2150mm

|

Final Products

Final Products of 2D CNC Stirrup Bender

Customer Photos

Highly-educated R&D team and tens years of manufacturing experience. Great regional advantages can help our clients with one-stop construction equipment supply, such as

Steel Bar Straightener And Cutter

, rebar bender, rebar cutter and so on

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Hot Searches