- Product Details

- {{item.text}}

Quick Details

-

Power:

-

4.0kw

-

Weight:

-

180 KG

-

Dimension(L*W*H):

-

1300*650*1350mm

-

Product name:

-

pork cube cutting machine chicken meat cutter

-

Function:

-

Slicing Frozen Meat

-

Usage:

-

Cuting Meat

-

Material:

-

304 Stainless Steel

-

Application:

-

Meat Processing Equipment

-

Color:

-

Silver

-

Type:

-

Meat Processing Machinery Fresh Meat Slicer

-

Capacity:

-

600-1200kg/h

-

Cutting Thickness:

-

Adjustable

-

Certification:

-

CE Certificate

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Huagang

-

Voltage:

-

220V/380V

-

Power:

-

4.0kw

-

Weight:

-

180 KG

-

Dimension(L*W*H):

-

1300*650*1350mm

-

Product name:

-

pork cube cutting machine chicken meat cutter

-

Function:

-

Slicing Frozen Meat

-

Usage:

-

Cuting Meat

-

Material:

-

304 Stainless Steel

-

Application:

-

Meat Processing Equipment

-

Color:

-

Silver

-

Type:

-

Meat Processing Machinery Fresh Meat Slicer

-

Capacity:

-

600-1200kg/h

-

Cutting Thickness:

-

Adjustable

-

Certification:

-

CE Certificate

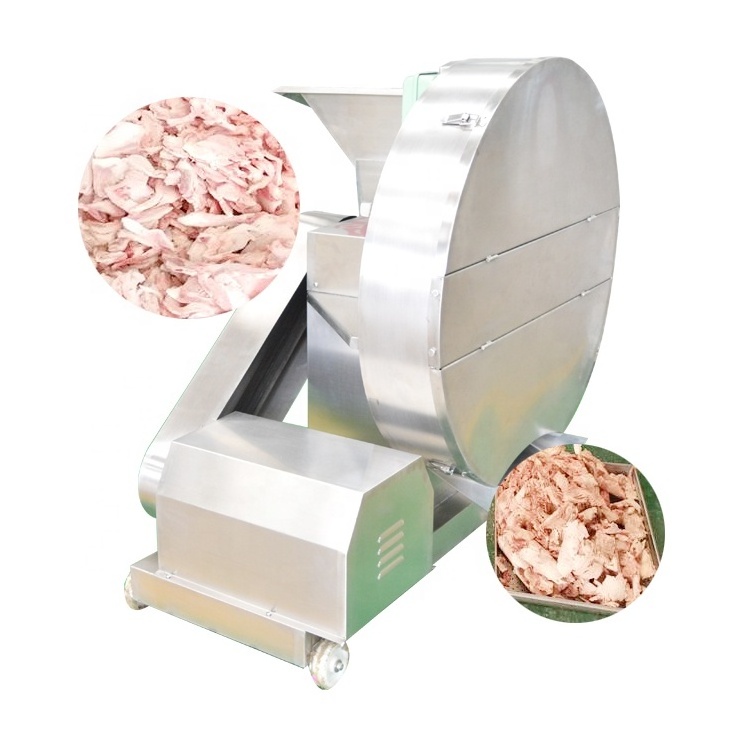

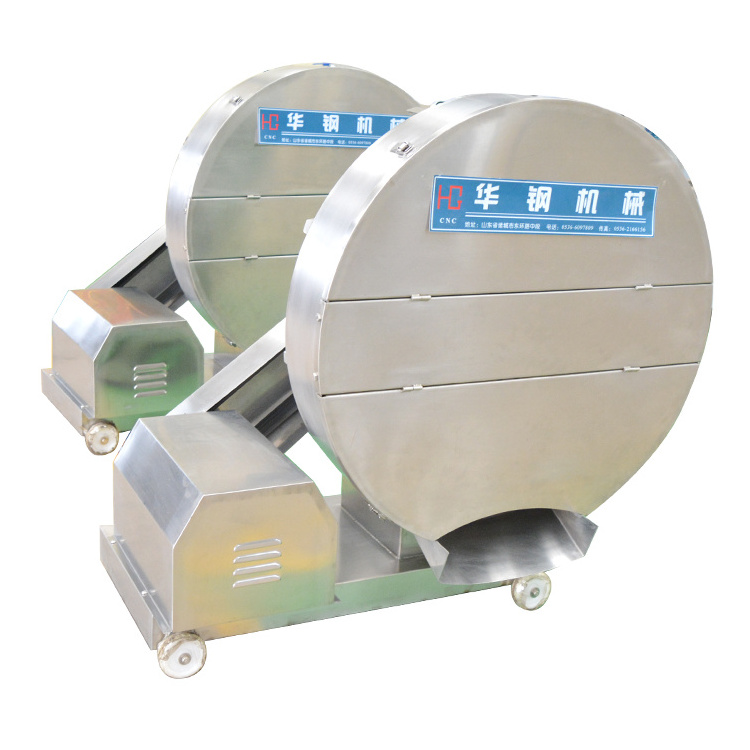

HUAGANG MACHINERY Stainless steel Frozen Meat Cutter machine frozen beef planer meat block breaker

Features for Big output pork cube cutting machine chicken meat cutter frozen beef planer meat block breaker

1.Big output pork cube cutting machine chicken meat cutter frozen beef planer meat block breaker is used on flaking or slicing frozen meat block, no need to unfrozen, directly flaking in to slices,it can slice frozen meat of -18°C to thin pieces by slow rotation of cutting blades

2.The thickness can be adjusted. It reduces the cut off of meat fibers and minimizes waste, automatic frozen meat slicing machine can be used together with chopper mixer, which will long the life to chopper mixer.

3.Meat planer machine comprises frame, cutting structure, electirc cambinet, drive line system and motor. It is completely made of stanless steel, there are two knives on the disk. There are safety guards in the inlet and outlet.

Advantages for Big output pork cube cutting machine chicken meat cutter frozen beef planer meat block breaker

1.Adopts the international advanced technology, the whole structure stainless steel.

2. low noise, smooth operation and energy conservation.

3. Flaking by the fast rotating blade, flaking thickness can be adjusted between 5 and 15mm, fast flaking, high efficiency.

4. Appearance beautiful and easy, safe in operation, simple, easy tear open outfit cleaning.

5. After flaking, meat can be easily grinding and cutting by bowl chopper machine, so bowl chopper is easy working and keep longer life.

Technical parameters for Big output pork cube cutting machine chicken meat cutter frozen beef planer meat block breaker

| Model | BR-960 |

|

Cutter diameter(mm ) |

960 |

| Power(kw) | 4.0 |

| Capacity(kg/h) | 600-1200 |

| Thickness of slicer(mm) | Adjustable |

| Dimension(mm) | 1300*650*1350 |

QP-650 frozen meat planer is specially developed for crushing meat without bone frozen from - 18 C to - 24 C. It is directly cut into small pieces or sheets.

The production capacity is 4-5 tons per hour. This machine saves the understanding of frozen section, greatly shortens the meat processing time, reduces the cost and time, maintains the freshness of meat, reduces the infection rate of bacteria, and improves the product quality.

It can cut frozen meat from unthaw ing from - 18 ℃ to -24 ℃ , 5 - 40 kg into pieces or flakes directly. It is the preceding process of chopper and meat grinder, and is also the preferred equipment for pre-treatment in oil plant. The frozen meat slicing machine can cut all the standard meat pieces into slices in 13 seconds. Avoid pollution and nutrient loss caused by the mitigation process, ensure the freshness of meat, can save the ice refrigeration process, reduce the user refrigeration costs. Automatic production line can be customized according to customer requirements, saving labor and improving production efficiency.

| Model | QP-650 |

| Dimension(L*W*H) | 1750*945*1220mm |

| Capacity | 4tons/h |

| Power | 11kw |

| Width of discharge | 650mm |

| Trip of push knife | 680mm |

| Weight | 500kg |

| Material | 304 stainless steel |

Step 1: Firstly, the product is wrapped with stretched film.

Step 2: Secondly, put the

product

in and around the iron frame.

Step 3: Thirdly, the smoke proof board is sealed around the

product

for export.

Step 4: Finally, the packaged

product

is shipped.