Variety shapes are available for ball, tube, stick, ring, fruit loop, star, wheel and flower and heart shape by adjusting the mould in the extruder.

we could design the moulds with novel shapes according to customers'specific requirement on the shapes of their aimed products.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/50HZ adjustable

-

Power:

-

45kw

-

Weight:

-

3000 KG

-

Dimension(L*W*H):

-

2900*1500*1900mm

-

Year:

-

2024

-

Application:

-

puff snack machine

-

Feature:

-

High Efficiency Easy Operation

-

Raw material:

-

Corn Flour; Rice Flour; Or other cereal flour

-

Capacity:

-

300-400kg/h

-

Type:

-

Double Screw Extruder Machine

-

Material:

-

Stainless Steel 304 Food Grade

-

Inverter:

-

Delta

-

Energy:

-

Electricity, Steam, Gas

-

Relay:

-

Omron Relay

-

Diameter of screw:

-

85mm

Quick Details

-

Marketing Type:

-

New Product 2024

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Himax

-

Voltage:

-

380V/50HZ adjustable

-

Power:

-

45kw

-

Weight:

-

3000 KG

-

Dimension(L*W*H):

-

2900*1500*1900mm

-

Year:

-

2024

-

Application:

-

puff snack machine

-

Feature:

-

High Efficiency Easy Operation

-

Raw material:

-

Corn Flour; Rice Flour; Or other cereal flour

-

Capacity:

-

300-400kg/h

-

Type:

-

Double Screw Extruder Machine

-

Material:

-

Stainless Steel 304 Food Grade

-

Inverter:

-

Delta

-

Energy:

-

Electricity, Steam, Gas

-

Relay:

-

Omron Relay

-

Diameter of screw:

-

85mm

Production Description

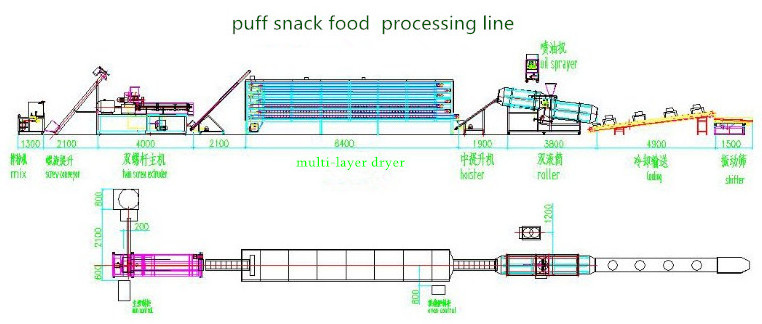

Puff snack food processing line ,We can generalize the puff snack foods production with "Low cost, high profits". This processing line can be used for the production all kinds of puff snacks, we will design the moulds with novel shapes according to customers'specific requirement on the shapes of their aimed products. The production line is from feeding materials, extruding,Forming,Filling and cutting, drying, oil spraying to finished products are done once time fully automatically.

*Capacity:100-150kg/h;200-260kg/h;300-500kg/h;1000kg/h

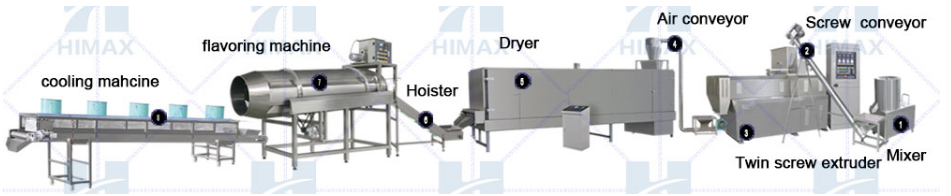

Flow chart of corn puff production line:

Mixer→Screw conveyer→Extruder→Air conveyer→Multi layer dryer

→

Hoister→

flavoring→

cooling machine→Packing machine

Our engineer could design the layout drawing according to your dimension of the factory for the whole processing Lines.

Raw material:

corn flour, wheat flour, rice flour, and other grains flour etc.

Puff Corn Snack Food Final product Photo

Product parameters

part of twin screw extruder model and capacity option for customer to choose

|

Model

|

Installed Power

|

Output

|

Size

|

|

HM65

|

74KW

|

100-150KG/H

|

28000*1200*2200mm

|

|

HM75

|

105KW

|

200-260KG/H

|

32000*1500*2200mm

|

|

HM85

|

205KW

|

300-600KG/H

|

35000*1500*3500mm

|

|

HM90

|

310KW

|

800-1000KG/H

|

38000*1500*4000mm

|

Voltage Three phases: 380V/50Hz, Single phase: 220V/50Hz, and we can customize it according to customers' local voltage.

Detailed Parts

mixer

mixer makes the raw material adding to water and liquid chemical additive fully mixed

Features:

1.This part that touches mixer to material adopts the stainless steel material.

2. The discharge hole adopts the new handle-opened design. It has the good seal so that the materials.

Features:

1.This part that touches mixer to material adopts the stainless steel material.

2. The discharge hole adopts the new handle-opened design. It has the good seal so that the materials.

Screw Conveyor

The mixed materials can be conveyed in the stainless steel roller to the feeding machine (feeder) of extruder without any leaking,

dusting and pollution; Feed quantity and speed is even and stable.

dusting and pollution; Feed quantity and speed is even and stable.

Multi layer Dryer

The heating way is gas/furel oil heating.

The net belt running speed can be controlled to change the food drying time in the dryer.

The temperature also can be controlled.

Multi-layer dryer is with compact size than other type dryers.

The net belt running speed can be controlled to change the food drying time in the dryer.

The temperature also can be controlled.

Multi-layer dryer is with compact size than other type dryers.

Hoister

.

Hoister conveys the food from the low to high, according to the craft; decide the hoister height and the level distance.

Hoister can be classified into big and small according to the hoister height and the level distance.

Hoister can be classified into big and small according to the hoister height and the level distance.

Rollers with flavor

different speed which controlled by the soft start.

With the two drums, the food can be flavored well.

There are several fans which can make the food be cool avoiding sticking together and be suitable for packing .

The total length of the conveyor is 5 meters. It is full set stainless steel

PRODUCTION REAL SHOT

Packaging & Shipping

--We are allowed to shipping by sea or by train.If you have another requirements about

shipment methods,we will acceept the agreements by negotiating with us.

--Inside package is plastic film, outside is plywood case(based on the customers' need).

shipment methods,we will acceept the agreements by negotiating with us.

--Inside package is plastic film, outside is plywood case(based on the customers' need).

Hot Searches