- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Ritong

-

Dimension(L*W*H):

-

customized

-

Capacity:

-

customized, customized

-

Weight:

-

3000

-

Design Pressure(MPa):

-

2

-

Design Standard:

-

GB150

-

Working Temperature(℃):

-

150 - 220 ℃

-

heating way:

-

steam boiler/electricity/conducting oil

-

material:

-

Q345R

-

control system:

-

automatic with Siemens PLC

-

function:

-

high temperature high pressure

-

Name:

-

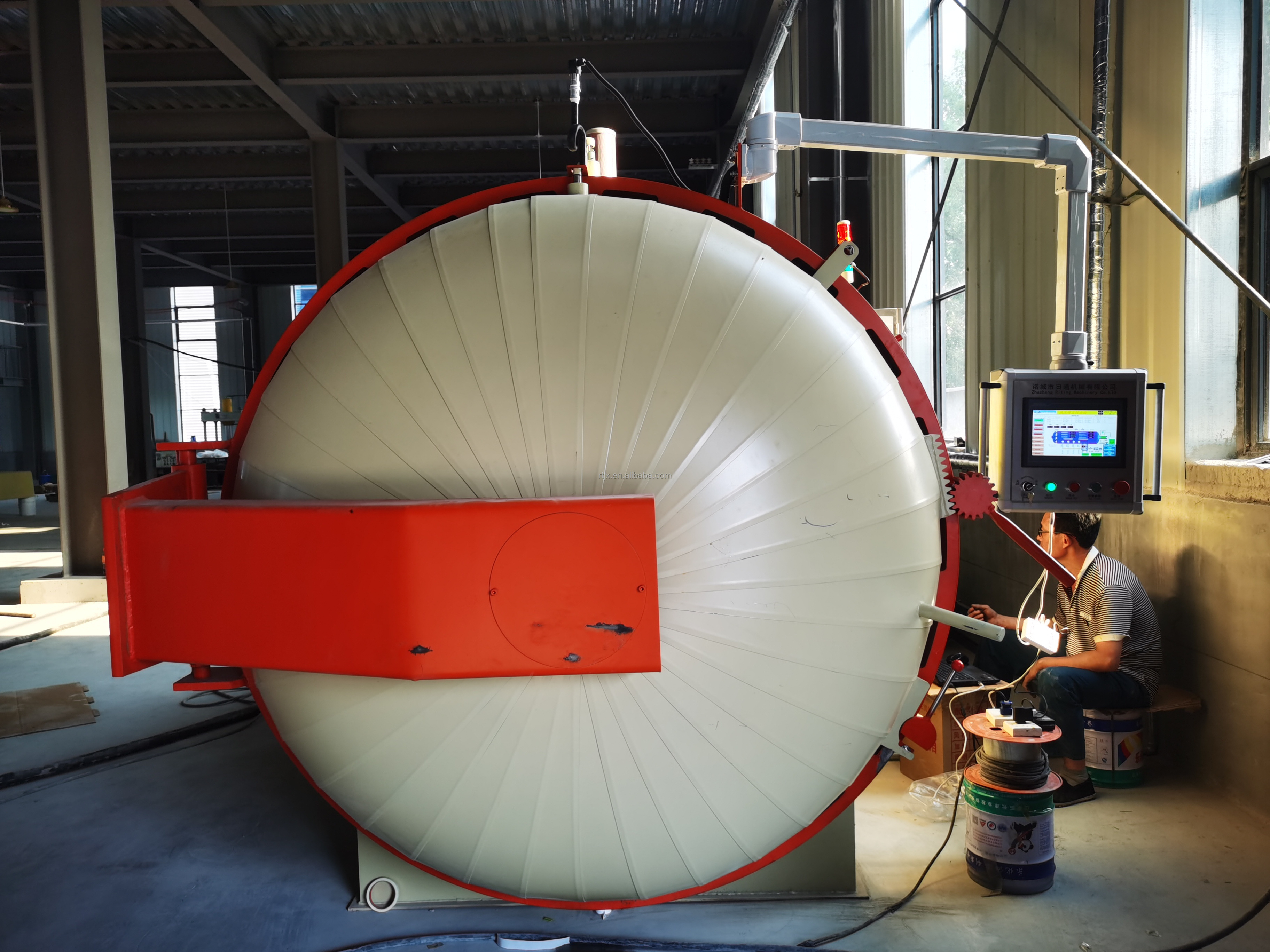

High Quality Automatic Composite Glass Fiber Autoclave

-

Category:

-

pressure vessel

-

Medium:

-

hot air

-

Control mode:

-

Siemens PLC

-

Application:

-

composite material

Quick Details

-

Volume (m³):

-

as per the dimension

-

Max Working Pressure(MPa):

-

1.7MPa

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Ritong

-

Dimension(L*W*H):

-

customized

-

Capacity:

-

customized, customized

-

Weight:

-

3000

-

Design Pressure(MPa):

-

2

-

Design Standard:

-

GB150

-

Working Temperature(℃):

-

150 - 220 ℃

-

heating way:

-

steam boiler/electricity/conducting oil

-

material:

-

Q345R

-

control system:

-

automatic with Siemens PLC

-

function:

-

high temperature high pressure

-

Name:

-

High Quality Automatic Composite Glass Fiber Autoclave

-

Category:

-

pressure vessel

-

Medium:

-

hot air

-

Control mode:

-

Siemens PLC

-

Application:

-

composite material

About Ritong

Zhucheng Ritong Machinery Co., Ltd. established in 2003, possesses manufacture qualification of pressure vessels with certification number of TS2237125-2026 and has attained European CE certifications. We have independent import and export rights and are mainly engaged in Class I pressure vessels industries.

Technical support

Zhucheng Ritong machinery Co., LTD. ensure the smooth implementation of projects, ensure the production line and the single machine equipment, implement the safe and reliable operation of the zero distance service marketing idea, the comprehensive

implementation "three five-star" service.

implementation "three five-star" service.

Pre-sale service

Provide the related industry information; free

Provide free project analysis and feasibility report;

Free for the factory of the plane design and the related equipment;

Provide free project analysis and feasibility report;

Free for the factory of the plane design and the related equipment;

Sale service

Free technology and business shangzhong rd;

Free to the user operation and maintenance personnel's standardized training;

Free installation of equipment, and a second training;

Free to the user operation and maintenance personnel's standardized training;

Free installation of equipment, and a second training;

After-sales service

Purchased equipment of quality guarantee for one year, lifelong maintenance;

Open 24 hours service hotline at (0536-6089755), visit and humbly accept your contact with us;

Equipped with tour designed for six, held once a year "in truth, all emotion" is the national tour services;

Key area set up service network, and the implementation of "zero distance" sincere service;

Open 24 hours service hotline at (0536-6089755), visit and humbly accept your contact with us;

Equipped with tour designed for six, held once a year "in truth, all emotion" is the national tour services;

Key area set up service network, and the implementation of "zero distance" sincere service;

Five in place

Around the pre-sale, sale and after-sale service implementation five in place, namely, personnel training, service personnel, accessories, maintenance technology and service delivery-to timely and effective image, to ensure that the user satisfaction of 100%.

SUCCESSFUL PROJECT

Products Description

GLASS FIBER AUTOCLAVE

1. TYPE: Electric heating , steaming for boiler , circulation oil

2. MEDIUM : air, water ,steaming, circulation oil

3.CONTROL MANNERS : Manual ,semi-automatic and fully automatic

4. Diameter, length ,design pressure and temperature done under customers requirements .

2. MEDIUM : air, water ,steaming, circulation oil

3.CONTROL MANNERS : Manual ,semi-automatic and fully automatic

4. Diameter, length ,design pressure and temperature done under customers requirements .

APPLICATION SCOPE

Composite material processing. Carbon fiber, boron fiber, aramid fiber, glass fiber, metal composites, reinforced plastics and etc..

Widely used in aircraft, missiles, satellites and space shuttle, such as the airplane cabin door, fairing, airborne radar cover,

the plane bracket, empennage.

Composite material processing. Carbon fiber, boron fiber, aramid fiber, glass fiber, metal composites, reinforced plastics and etc..

Widely used in aircraft, missiles, satellites and space shuttle, such as the airplane cabin door, fairing, airborne radar cover,

the plane bracket, empennage.

Autoclave Characters :

1. Electric curing ensure effective heating all around the interior chamber

2. Motor fans make air evenly circulation for temperature distribution better

3. Double channel PLC /PID control system, alternative control channel guarantee the presetted process progressive while the

autoclave accident happens.

4. Vacuum port connect with the vacuum bags pressure, control and detecting independent.

5. Interior air circulation system

6. Chamber and motor cooling system

7. Auto door leaf with oil cylinder control

8. Each vacuum port independent control and detecting

9. Temperature ,pressure and time pre-setted and adjustable

10. Interior and outside Insulation

Autoclave specification need to confirm with you, diameter ,length ,pressure ,temperature ect .

1. Electric curing ensure effective heating all around the interior chamber

2. Motor fans make air evenly circulation for temperature distribution better

3. Double channel PLC /PID control system, alternative control channel guarantee the presetted process progressive while the

autoclave accident happens.

4. Vacuum port connect with the vacuum bags pressure, control and detecting independent.

5. Interior air circulation system

6. Chamber and motor cooling system

7. Auto door leaf with oil cylinder control

8. Each vacuum port independent control and detecting

9. Temperature ,pressure and time pre-setted and adjustable

10. Interior and outside Insulation

Autoclave specification need to confirm with you, diameter ,length ,pressure ,temperature ect .

About delivery

We will delivery your goods by LCL/20' FCL/40'FCL depending on your order. Before delivery, our professional engineer will do trial run for each machine to check and confirm everything is workable, you also can come to our factory for testing together with us. When loading, our workers will fix the machine tightly in the container to ensure the safety in the transportation.

Details Images

Certifications

Hot Searches