- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

TN

-

Voltage:

-

220 VAC

-

Power:

-

2000 W

-

Dimension(L*W*H):

-

1100*900*1450mm

-

Weight (KG):

-

350

-

Application:

-

Preparation of Metals Semiconductors and Insulators

-

Technology:

-

Magnetron Sputtering

-

Keywords:

-

Magnetron Sputtering System

-

Coating color:

-

Customers' Requirement

-

Coating Technology:

-

Vacuum Magnetron Coating

-

Product name:

-

Magnetron Sputtering System

-

MOQ:

-

1

-

Model:

-

CY-VTC-3HD

-

Chamber size:

-

300mm Dia.*300mm H.

-

Training:

-

Operation Training

Quick Details

-

Machine Type:

-

Lab research, Coating Equipment

-

Marketing Type:

-

Hot Product 2023

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

TN

-

Voltage:

-

220 VAC

-

Power:

-

2000 W

-

Dimension(L*W*H):

-

1100*900*1450mm

-

Weight (KG):

-

350

-

Application:

-

Preparation of Metals Semiconductors and Insulators

-

Technology:

-

Magnetron Sputtering

-

Keywords:

-

Magnetron Sputtering System

-

Coating color:

-

Customers' Requirement

-

Coating Technology:

-

Vacuum Magnetron Coating

-

Product name:

-

Magnetron Sputtering System

-

MOQ:

-

1

-

Model:

-

CY-VTC-3HD

-

Chamber size:

-

300mm Dia.*300mm H.

-

Training:

-

Operation Training

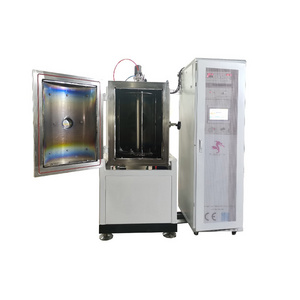

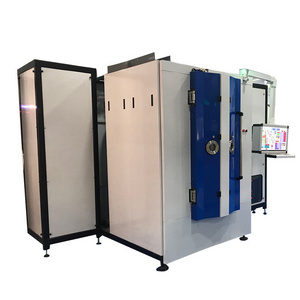

Metal Semiconductor and Insulator Film Confocal Vacuum PVD Magnetron Sputtering System

VTC-3HD is a combinatorial plasma sputtering system with three 2'' magnetron sputtering sources and three RF/DC power supplies. Such a sputtering system is capable of co-sputtering up to three different target materials and create various composition profiles across the substrate (e.g. ternary materials for Li-ion rechargeable battery). This system is also suitable for sequential coating of multiple layer films such as ferroelectric, alloy, semiconductor, ceramic, dielectric, optical, oxide, hard, PTFE, etc.

Specifications

|

Input Power |

Single phase 220 VAC 50/60 Hz 2000 W (including vacuum pump and water chiller) |

|

Source Power |

Three sputtering power sources are integrated into one control box. DC source: 500 W power for coating metallic materials RF source: 500 W power, 13.56 MHz frequency for coating non-conductive materials |

|

Magnetron Sputtering Head |

Three 2" Magnetron Sputtering Heads with water cooling jackets and shutters are included Target size requirement: 2" diameter Thickness range: 0.1 - 3 mm for both metallic and non-conductive targets (including backing plate)

|

|

Vacuum Chamber |

Vacuum chamber: 300 mm Dia. x 300 mm Height, made of stainless steel Viewport: 100 mm Dia. |

|

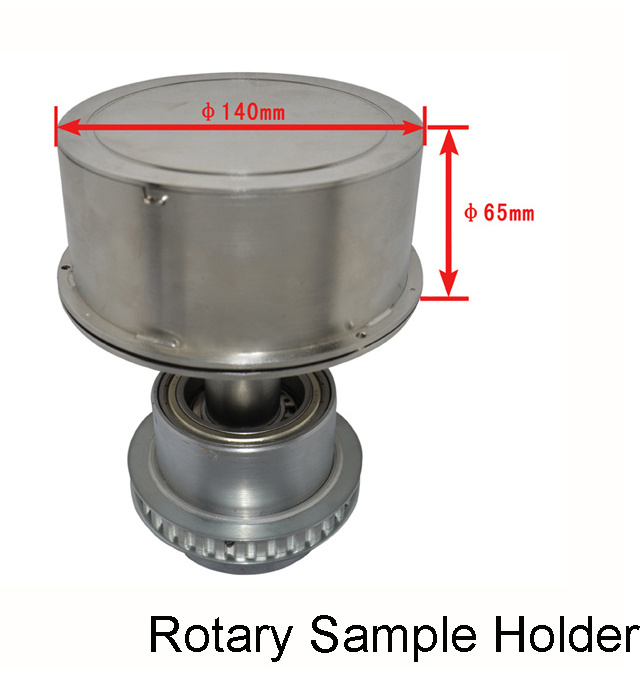

Sample Stage |

Sample holder is a rotatable and heatable stage made of ceramic heater with copper cover Sample holder size: 150 mm Dia. Rotation speed: 1 - 20 rpm adjustable for uniform coating The holder temperature is adjustable from RT to 500 °C max |

|

Gas Flow Control |

Two precision mass flow controllers (MFC) are installed to allow inlet of two types of gases Flow rate: 0 – 200 mL/min & 0 - 100ml/min adjustable on the touch screen control panel Air inlet valve is installed for vacuum release |

|

Vacuum Pump Station |

Pumping speed 600L/s Vacuum degree: 10-4Pa. |

|

Water Chiller

|

One digital temperature controlled recirculating water chiller is included. Refrigeration range: 5~35 °C Flow rate: 16 L/min Pump pressure: 14 psi |

|

Warranty |

One year limited warranty with lifetime support |

Detailed Pictures

Plastic paper inside, polyfoam filled, wooden box outside or as your requirement.

Shipping and transportation as customer request. Generally, our mode of transport are by sea, by air or rail transport .

1 . Reply your inquiry in 24 working hours.

2. Experienced staffs answer all your questions in fluent English.

3. Customized design is available.

4. Exclusive and unique solution can be provided to our customer by our well-trained and professional engineers and staff.

5. Professional factory : We are manufacturer, specializing in laboratory equipment.