- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V/440V

-

Power:

-

90kw

-

Weight:

-

3600 KG

-

Dimension(L*W*H):

-

depend on capacity

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

company name:

-

Shanghai Jimei Food Machinery Co.,Ltd

-

product name:

-

Yogurt processing line plant/milk machine

-

work: full:

-

full automatic.

-

project:

-

from A to Z turn-key project

-

raw material:

-

fresh milk or milk powder

-

capacity:

-

the smallest is 500L per hour

-

machine structure:

-

high quality stainless steel SUS304

-

package:

-

plastic cup,paper cup,carton,bottle,etc

-

operation:

-

automatic PLC,touch screen,man-machine interface

Quick Details

-

Marketing Type:

-

yogurt processing machine

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Shanghai Jimei

-

Voltage:

-

220V/380V/440V

-

Power:

-

90kw

-

Weight:

-

3600 KG

-

Dimension(L*W*H):

-

depend on capacity

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

company name:

-

Shanghai Jimei Food Machinery Co.,Ltd

-

product name:

-

Yogurt processing line plant/milk machine

-

work: full:

-

full automatic.

-

project:

-

from A to Z turn-key project

-

raw material:

-

fresh milk or milk powder

-

capacity:

-

the smallest is 500L per hour

-

machine structure:

-

high quality stainless steel SUS304

-

package:

-

plastic cup,paper cup,carton,bottle,etc

-

operation:

-

automatic PLC,touch screen,man-machine interface

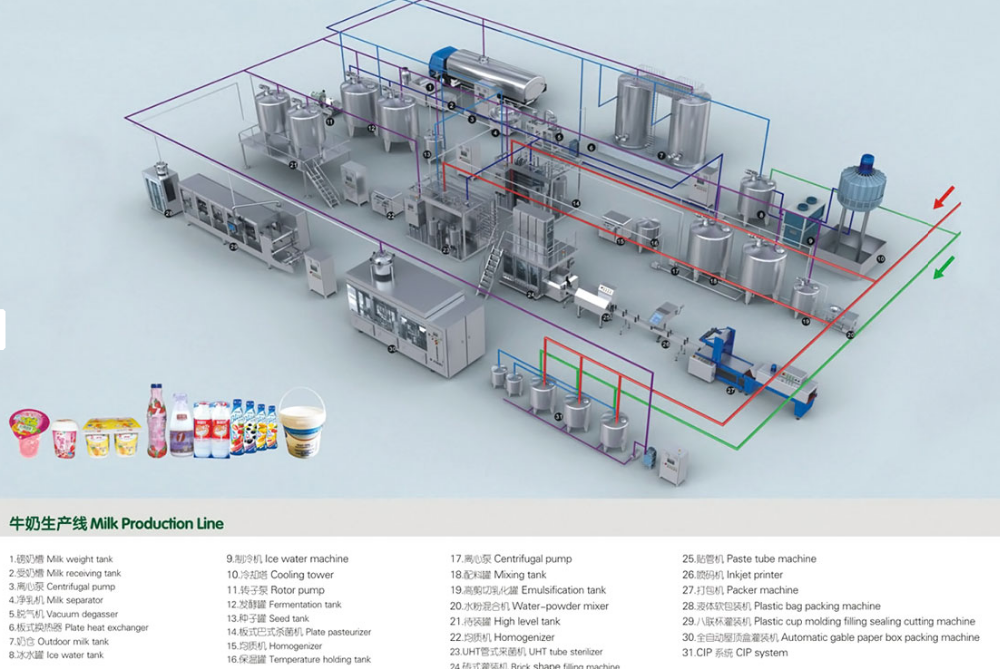

A complete dairy milk yogurt production plant as below pictures

Description

|

Technical parameters

|

|

|

||

|

1

|

Raw material

|

Milk or milk powder

|

||

|

2

|

Product

|

UHT milk,dairy products,yogurt

|

||

|

3

|

Terminal package

|

Carton brick, plastic bag, tin,can,plastic bottle depends on your choice

|

||

|

4

|

We can design it according to your special requirements.

|

|

||

The Whole Producion Line Including Below Items:

2.Ingredients sterilization system

3.Filling &Packing system

4.CIP cleaning system

5.Water treatment system

6.Water Supply system

7.Steam System

8.Air Compressed System

9.Refrigeration Systems

Commercial milk and yogurt production line making processing machine plant

The pretreatment of the milk is the same, regardless of whether set or stirred yoghurt is to be produced. It includes standardization of the fat and dry matter contents, heat treatment and homogenization. It is assumed that the milk has been standardized to the required fat content before entering the line and standardization of the dry matter content takes place in an evaporator in the process line. If the dry matter content is adjusted by addition of milk powder, the equipment used is similar to that described under "Recombined milk". Any additives, such as stabilizers, vitamins, etc., can be metered into the milk before the heat treatment. When the yoghurt milk has been pretreated and cooled to inoculation temperature, the procedure for further treatment depends on whether set, stirred, drink, frozen or concentrated yoghurt is to be produced.

|

SPECIFICATIONS FOR Yogurt Production Line

|

|

|

|

|||

|

Raw material

|

Fresh cow milk , powder milk

|

|

|

|||

|

production

|

Stirred yoghurt, Set yoghurt, Drinking yoghurt,etc

|

|

|

|||

|

Capacity

|

2T/D–500T/D

|

|

|

|||

|

Endproduct package

|

Gabletop carton,plastic bottle,plastic cup,glass bottle,etc

|

|

|

|||

The whole line including:

1.Ingredients sterilization system

101.High shear emulsification tank

102.Water-Powder Mixer

103.Mixing tank

104.Double filter

105.Plate sterilizer

106. Homogenizer

107.Fermentation tank

108.Plate heat exchanger

109.Rotor pump

110.High storage tank

110.Centrifugal pump

111.CIP Return pump

2. Filling and Packing system

201.3 in 1 filling machine

202. Automatic sleeve labeling machine

203. inkjet printer

206.Cup filling machine

3. CIP cleaning system

301. Integrated CIP washing machine

4. Water treatment system

401.RO water treatment water unit

402.Water tank 2000L 31

5.Steam System

501.Industrial fuel vertical boiler

6.Air Compressed System

601.Air compressor

602.Air filter

603.Air dryer

604.Air storage tank

7.Refrigeration Systems

701.Air-cooled chiller

702.Ice water tank

703. water pump

704.Fermentation room

705.Low temperature cold storage