- Product Details

- {{item.text}}

Quick Details

-

Tubing Diameter:

-

O.D. 7.0mm

-

Hairpin length:

-

100-2000mm

-

Working efficiency:

-

7.0 *5 tubes/cycle

-

Normal voltage:

-

380V, 3P, 50Hz

-

Type:

-

Semi-automatic

-

Color:

-

Customer's Requirement

-

Model:

-

BWJ-2000

-

Brand:

-

Wondery

-

Power:

-

380V

-

After Warranty Service:

-

Online support

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

WONDERY

-

Weight (KG):

-

1500

-

Tubing Diameter:

-

O.D. 7.0mm

-

Hairpin length:

-

100-2000mm

-

Working efficiency:

-

7.0 *5 tubes/cycle

-

Normal voltage:

-

380V, 3P, 50Hz

-

Type:

-

Semi-automatic

-

Color:

-

Customer's Requirement

-

Model:

-

BWJ-2000

-

Brand:

-

Wondery

-

Power:

-

380V

-

After Warranty Service:

-

Online support

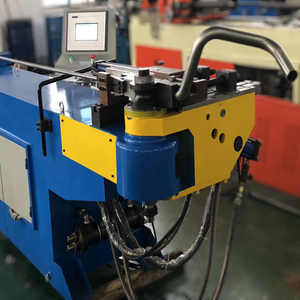

Semi-automatic Hairpin Tube Bending Machine

PRODUCTS DESCRIPTION

|

Technical Parameters

|

|

1 Tubing Diameter: O.D. 7.0mm

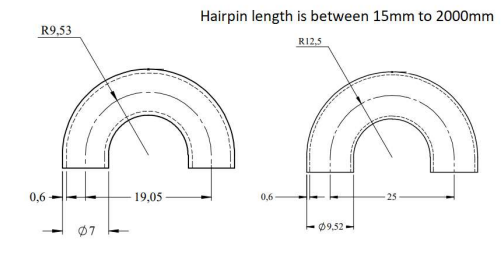

2. Hairpin length:100-2000mm

3. Working efficiency: 7.0 *5 tubes/cycle

4. Normal voltage: 380V, 3P, 50Hz

|

|

Structure Characters

|

|

1. Compact design, Servo motor driving, Manual feeding, Operation in manual or automatic mode For option

2. Process of automatic operation mode is material feeding by manual →mould tooling clamping→ oil spraying during the bending → bending → mandrel back → clamp loose → unloading → unloading home → bending tooling home

3. Hairpin Leg difference in length less than 0.5mm

4. No obvious clashing, abnormal “bump”, corrugation neither other deficiency. Ellipse less than 8% 5. Roundness tolerance of bend area.

|

|

Performance parameters of machine

|

|

1. Working efficiency: 12 seconds per cycle taking 1 meter as example. Pneumatic air consumption 3.5 cfm

2. Air cooled

3. Light curtain will be installed for safety guard

|

|

Lubrication system

|

|

Expanding rod with lubrication holes and control by solenoid valve which allow oil spray every setting seconds (Injection time can be adjusted)

|

Detailed Images

Warranty

The machine is warranted for 12 months starting from the day of arrival at the buyer’site. Easy worn parts are not included in the warranty.

Confidentiality

The buyer is not allowed to pass the technical documents to a third party without permission of the seller.

Technical Parameters

1. The tube material is aluminum. Tube’s outer diameter is 7mm and 9.5mm. The wall thickness is 0.60mm. The machine is capable of bending 19.05mm axis for 7mm tube and 25mm axis for 9.5mm tube

2. There will be security fences at three sides of the machine. A safety barrier will be provided separately by the seller. There will be contact input in the electrical control box. It is the buyer's responsibility to install the safety barrier.

3. Machine’s color is RAL 5005 Signal blue. The electric circuit box is RAL 7035 Light gray. The protection area is RAL 1021 rapeseed yellow

4. The machine must have CE certification and fully meet CE certification requirements.

5. Machine will provide 24V signal for 1 second at the end of every cycle.

6. There will be 3 layers of tower lamb with a warning buzzer on the machine.

7. There will be a security switch at the doors and an emergency stop button on the electrical control box.

Wuxi Wondery Industry Equipment Co., Ltd

.

is a professional supplier of industrial machines. Currently the company mainly supplies the equipment for the automobile industry, household air conditioner industry, engineering vehicle industry, power generation plant industry, train industry, ship industry, etc. Our main products are: radiator making machines, aluminum fin machine, aluminum radiator core builder machine, aluminum radiator plastic tank clinching machine, aluminum radiator brazing furnace, aluminum header pipe punching machine, aluminum flat tube straightening and cutting machine, high speed fin press machine, aluminum/copper pipe straightening and cutting machine, tube expander machine, automatic bending machine, progressive fin die, metal punching die, etc. Established in year 2008, the company has gained rich experiences in development and design, quality control, and after-sales service. The company aims to serve every customer with quality products and excellent service. The company provides thoughtful services like technical consultation, installation and test-running, technical training, and maintenance. Our company is also able to design non-standard products as per customers' requests. We have exported our machines and equipment to the following countries and areas: Taiwan (CHINA), Vietnam, Thailand, Pakistan, India, Venezuela, Bolivia, Mexico, Argentina, Columbia, Australia, USA, Kenya, Ethiopia, Qatar, Egypt, etc. We are capable of providing thoughtful solutions for every individual customer based on their specific requirements, making sure that every potential customer is satisfied with our work.

1. What is the power supply of the heat exchanger making machines?

The power supply of heat exchanger making machines is to be decided by the customer's side. We are able to adjust the power supply (volt, and phase) through a transformer or of the customer's voltage directly so that the melting furnace is ready for use at the end user's site.

2. What information should the customer provide to get an accurate quotation from us?

The customer should provide the related technical requirements, drawings, pictures, industrial voltage, planned output, etc.

3. What is the payment term?

The payment term is 40% down payment, and 60% before delivery (T/T mode).

4. What is the delivery time?

The delivery time of the machine is 30-60 days after receipt of down payment.

Hot Searches