With 14 years of manufacturing experience, MORITA LASER has established a complete system of laser marking, cutting, welding and engraving technology development and manufacturing.

· Main products: laser cutting machine, fiber laser marking machine, CO2 laser marking machine, UV laser marking machine, crystal engraving machine, laser welding machine, laser cleaning machine, and other laser equipment.

- Product Details

- {{item.text}}

Quick Details

-

Cooling Mode:

-

Air Cooling

-

Control Software:

-

EZCAD2

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

MORITA

-

Marking Head Brand:

-

SINO

-

Weight (KG):

-

50 KG

-

Core Components:

-

laser source

-

Product name:

-

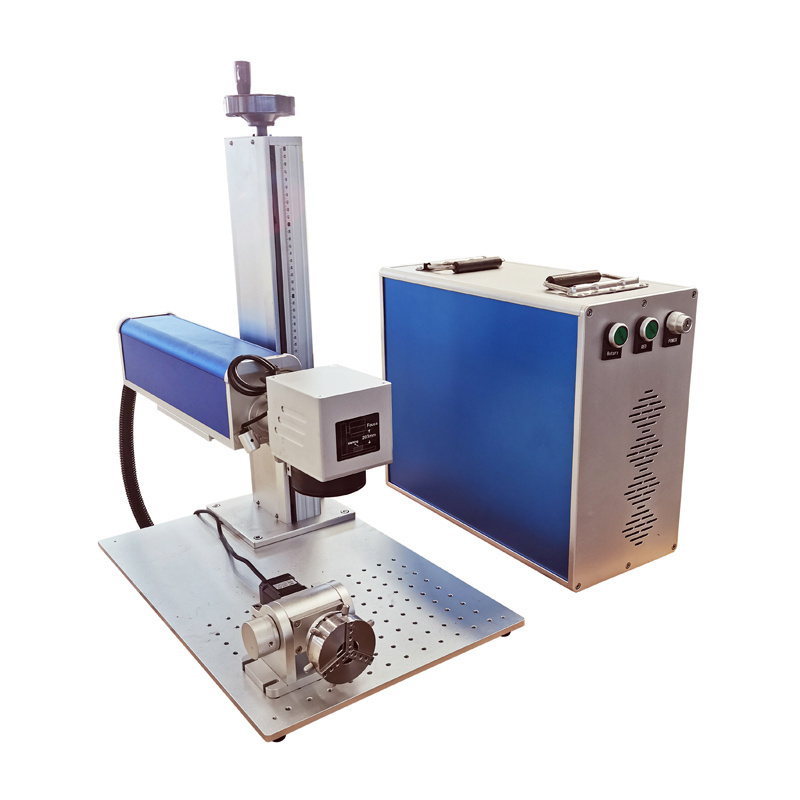

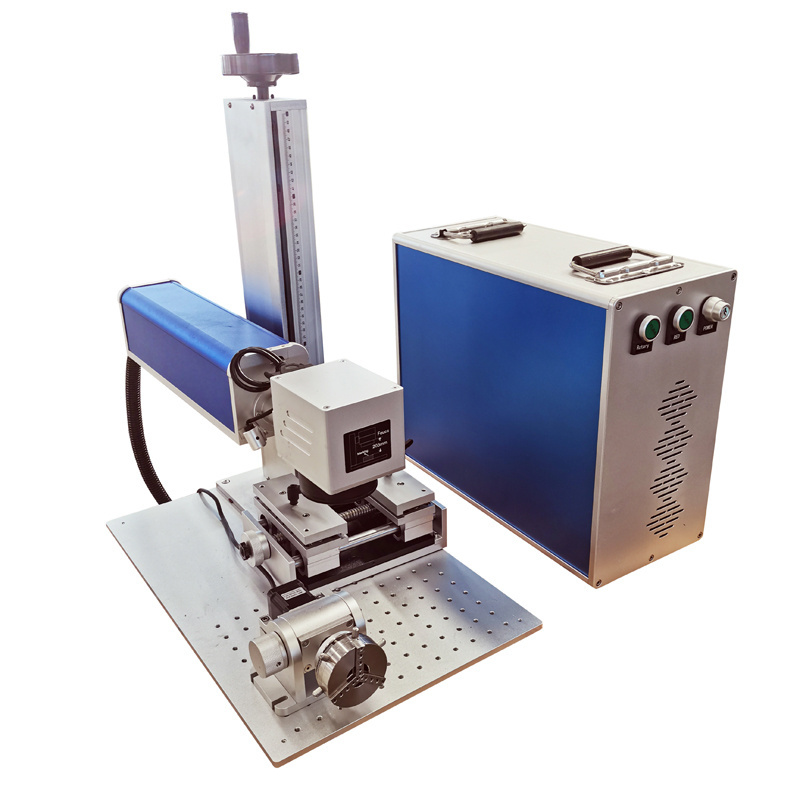

Desktop laser marking machine

-

Laser Life:

-

100000 hours

-

Appication Material:

-

Metal,Gold,Silver

Quick Details

-

Working Accuracy:

-

±0.001mm

-

Graphic Format Supported:

-

AI, PLT, DXF, BMP, Dst, Dwg, LAS, DXP

-

Laser Type:

-

Fiber Laser Marking

-

Cooling Mode:

-

Air Cooling

-

Control Software:

-

EZCAD2

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

MORITA

-

Marking Head Brand:

-

SINO

-

Weight (KG):

-

50 KG

-

Core Components:

-

laser source

-

Product name:

-

Desktop laser marking machine

-

Laser Life:

-

100000 hours

-

Appication Material:

-

Metal,Gold,Silver

Product Paramenters

|

Model

|

ST-F20

|

ST-F30

|

ST-F50

|

ST-F60

|

ST-F70

|

ST-F80

|

ST-F100

|

||||||

|

Power

|

20W

|

30W

|

50W

|

60W

|

70W

|

80W

|

100W

|

||||||

|

Laser Source Brand

|

JPT

|

|

|

|

|

|

|

||||||

|

Software

|

EZCAD2

|

|

|

|

|

|

|

||||||

|

Laser Life

|

100000+ hours

|

|

|

|

|

|

|

||||||

|

Working Format

|

50*50/110*110/150*150/175*175/200*200/260*260/300*300mm, etc.

|

|

|

|

|

|

|

||||||

|

Working Accuracy

|

±0.001mm

|

|

|

|

|

|

|

||||||

|

Laser Wavelength

|

1064nm

|

|

|

|

|

|

|

||||||

|

Working Power Supply

|

220V/110V

|

|

|

|

|

|

|

||||||

|

Cooling method

|

Air cooled

|

|

|

|

|

|

|

||||||

|

Machine Cabinet Size

|

210*450*440mm

|

|

|

|

|

|

|

||||||

|

Mass Weight

|

50KG

|

|

|

|

|

|

|

||||||

|

Appication Material

|

Metal: Gold, Silver, Brass, Copper, Carbon Steel, Stainless Steel, Aluminum, Anodized Aluminum, Titanium, Chrome,etc.

Hard Plastic: PF,PU, EP, UPR, FF, SI, AN,etc.

|

|

|

|

|

|

|

||||||

|

Optional

|

Rotary Axis / Lifting Table / Auto Lifting Table / Autofocus

|

|

|

|

|

|

|

||||||

Details

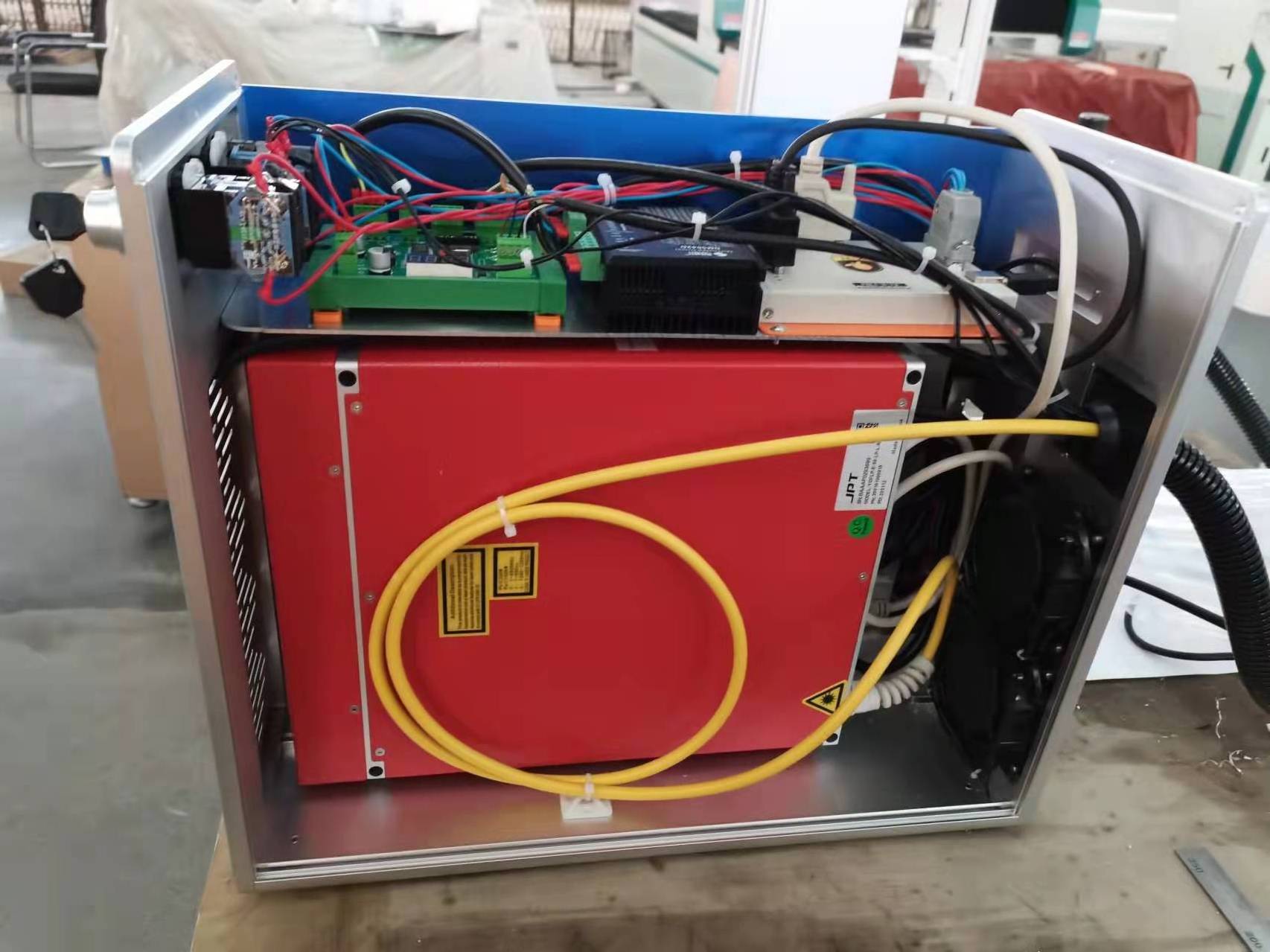

JPT Laser Source

The pulse repetition frequency and pulse width of the JPT laser source can be independently controlled in the MOPA configuration, which can well maintain the peak power of the laser.

JCZ Control Software

Using EZCAD control software, the software supports files in multiple formats, such as plt, dxf, ai, dst, jpg, etc., and the

operation is simple.

operation is simple.

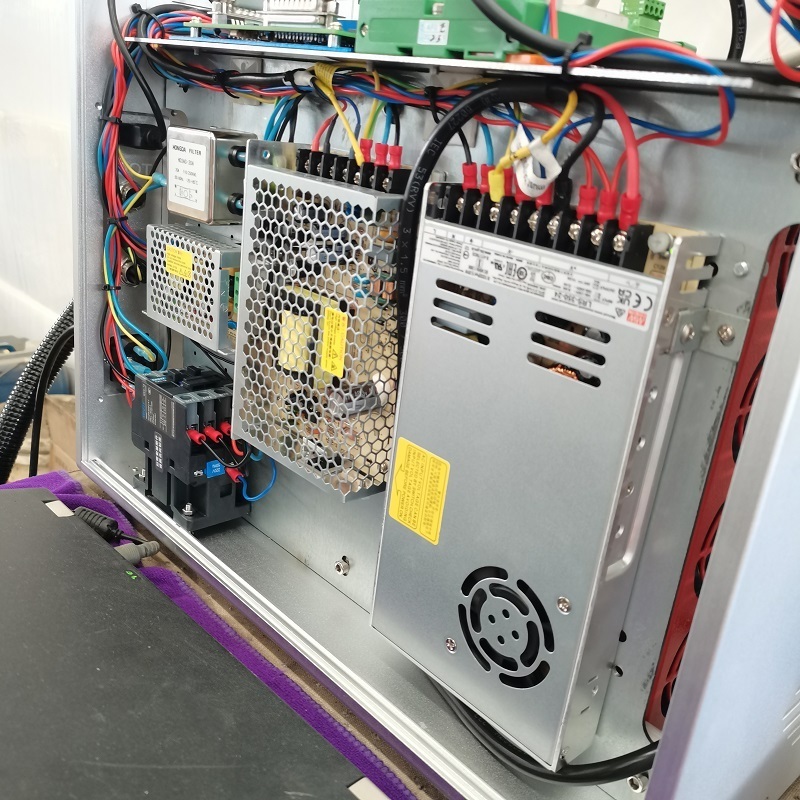

Electrical Cabinet .

Meanwell power supply

more stable and secure

SINO-Galvo

Two high speed motor control reflect lens inside the head, which give the machine max 7000mm/s marking speed.

Lense

Quartz lens, making marking more precise and finer

.

Button

Humanized control system, easy to operate, safe and convenient, dust proof design.

Optional

Auto Focus

Auto-focus makes the operation more convenient, without shaking the hand wheel by hand, which improves the production efficiency

Rotary

Optional specifications: 50mm, 69mm, 80mm, 100mm, 125mm, 160mm, etc.

Different products choose different specifications.

Metal Fixture

When you cut metal (such as metal pieces such as gold, silver, copper, etc.), it can play a role in fixing the metal.

Sample Display

Customer feedback

Packing & Delivery

Laser equipment is a relatively precise machine, beware of bump and friction in the process of transportation, which requires us to do a good job of packaging before transportation. Morita, as a professional manufacturer of laser equipment in China, has a lot of experience in packaging all kinds of laser equipment.

1. Wipe the machine, the machine is wiped clean, not only for beautiful, more important is to prevent the machine attached to the machine is in the process of transport of particles cut surface, damage the paint.

2. We will use stretch film to winding machine,let the machine with a layer of protective film, this is to let the machine during transport to prevent damage in the process offriction.

3. We’ll let the machine then wrapped with thick foam board, this can prevent machine in the process of transportation by knock against, impact.

4. Installation of wooden boxes, thick wooden cases like a layer of armor, can protect the machine to a

great extent.

5. In front of the cover in the middle of the machine and the cases filled with rubber cushion, this will prevent collision between machines and wooden case, can also further to package the machine.

Our factory

Our products and services are the best, we provide products to many suppliers and buyers, we attach great importance to product quality, we have 14 years of experience in manufacturing personnel to process and manufacture products, before the products are shipped, we have professional inspection personnel to test the products repeatedly, to ensure that the products are the best.

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 3-5 days if the goods are in stock. or it is 5-10 days if the goods are not in stock, it is according to

quantity.

Q: What is your terms of payment ?

A: Payment<=5000USD, 100% in advance. Payment>=10000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 3-5 days if the goods are in stock. or it is 5-10 days if the goods are not in stock, it is according to

quantity.

Q: What is your terms of payment ?

A: Payment<=5000USD, 100% in advance. Payment>=10000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

Hot Searches