- Product Details

- {{item.text}}

Quick Details

-

Power:

-

Customized

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

Customized

-

Warranty:

-

1 Year

-

Name:

-

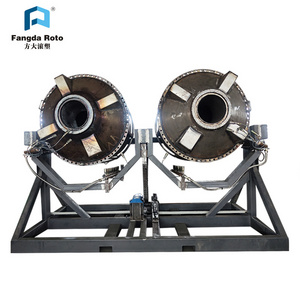

Rotational Molding Machine

-

Function:

-

Plastic Products Making

-

Product Type:

-

Mass Production

-

Oven Inner Dimension:

-

3.6*3.6*3.6m

-

Max. Temperature of Oven:

-

350 ℃

-

Oven Thickness:

-

150 mm

-

Noise:

-

None

-

Control Apparatus:

-

Siemens

-

Delivery Time:

-

Wthin 60 Days

-

Fuel:

-

LPG CNG

-

Marketing Type:

-

Hot Product 2021

-

Certification:

-

CE ISO9001

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Fangda Roto

-

Voltage:

-

Customized

-

Power:

-

Customized

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

Customized

-

Warranty:

-

1 Year

-

Name:

-

Rotational Molding Machine

-

Function:

-

Plastic Products Making

-

Product Type:

-

Mass Production

-

Oven Inner Dimension:

-

3.6*3.6*3.6m

-

Max. Temperature of Oven:

-

350 ℃

-

Oven Thickness:

-

150 mm

-

Noise:

-

None

-

Control Apparatus:

-

Siemens

-

Delivery Time:

-

Wthin 60 Days

-

Fuel:

-

LPG CNG

-

Marketing Type:

-

Hot Product 2021

-

Certification:

-

CE ISO9001

Product Description

Fanda Roto's Shuttle Rotomolding Machine is suitable large size products but not need mass quantity.

■ Application:Water Tank,Oil Tank,Cooler Box,Furniture,Urea Tank,Road blocks,Float,Auto Parts,Kayak,Boat and so on.

■ 3 Kinds of workarm for choice: Straight-arm,L style offset arm or C style offset arm to choose.

■ 3 Kinds of heat source for choice:Natural Gas,Liquefied Gas or Diesel Oil.

■ High effective and thermal insulated of heating chamber to low energy consumption and save cost.

■ Real-time monitoring the temperature of heating chamber to bring high quality products.

■ Remote fault diagnosis can be realized.

■ Application:Water Tank,Oil Tank,Cooler Box,Furniture,Urea Tank,Road blocks,Float,Auto Parts,Kayak,Boat and so on.

■ 3 Kinds of workarm for choice: Straight-arm,L style offset arm or C style offset arm to choose.

■ 3 Kinds of heat source for choice:Natural Gas,Liquefied Gas or Diesel Oil.

■ High effective and thermal insulated of heating chamber to low energy consumption and save cost.

■ Real-time monitoring the temperature of heating chamber to bring high quality products.

■ Remote fault diagnosis can be realized.

|

Technical Data Sheet

|

|

|

|

|

||||

|

Model No.

|

Machine Dimension(m)

|

|

|

Oven Inner Dimension(m)

|

||||

|

|

Length

|

Width

|

Height

|

|

||||

|

FD2-2600

|

13.0

|

5.6

|

4.0

|

2.6*2.6*2.6

|

||||

|

FD2-3100

|

14.7

|

6.1

|

4.5

|

3.1*3.1*3.1

|

||||

|

FD2-3600

|

16.3

|

6.8

|

5.0

|

3.6*3.6*3.6

|

||||

|

FD2-4100

|

18.0

|

7.5

|

5.5

|

4.1*4.1*4.1

|

||||

|

FD2-4600

|

20.0

|

8.0

|

6.0

|

4.6*4.6*4.6

|

||||

|

FD2-5100

|

22.0

|

8.7

|

6.5

|

5.1*5.1*5.1

|

||||

Product Advantages

1. Low cost rotational molding: the same size specifications of the product, the cost of rotational molding mold is about blow molding, injection mold costs 1/3 to 1/4;

2. Edge strength of rotomoulded products is good, rotational molding can realize the thickness of the edge of the product

more than 5 mm, and completely solve the problem that the edge of the hollow product is thin;

3. Rotational molding can place a variety of accessories;

4. The shape of rotomolding products can be very complicated, and the thickness of more than 5 mm;

5. Rotational molding can produce fully enclosed products;

6. Rotational molding products can be filled foam material, to achieve insulation;

7. No need to adjust the mold, rotational molding wall thickness can be freely adjusted(2mm above);

8. The product hollow seamless, but you can adjust the wall thickness, so that products with high strength;

9. Can provide a variety of surface pattern processing, production of various color products, anti-UV anti-aging treatment.

Hot Searches