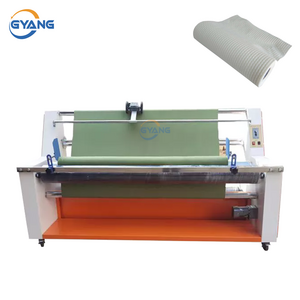

- Product Details

- {{item.text}}

Quick Details

-

Warranty of core components:

-

1 years

-

Core Components:

-

Transducer

-

Application:

-

Almost for all fabrics

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Altrasonic

-

Power:

-

500W, 500W

-

Dimension(L*W*H):

-

600*500*500mm

-

Weight:

-

15 KG

-

Features:

-

ultrasonic

-

Type:

-

HS-C25

-

Generator:

-

85-240V/50-60Hz

-

Frequency:

-

25kHz

-

Theoretical cutting thickness:

-

0~12mm

Quick Details

-

Production Capacity:

-

As your requirements

-

Voltage:

-

220V/380V

-

Marketing Type:

-

New Products

-

Warranty of core components:

-

1 years

-

Core Components:

-

Transducer

-

Application:

-

Almost for all fabrics

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Altrasonic

-

Power:

-

500W, 500W

-

Dimension(L*W*H):

-

600*500*500mm

-

Weight:

-

15 KG

-

Features:

-

ultrasonic

-

Type:

-

HS-C25

-

Generator:

-

85-240V/50-60Hz

-

Frequency:

-

25kHz

-

Theoretical cutting thickness:

-

0~12mm

Specification

|

Type

|

HS-C25

|

|

Generator

|

85-240V/50-60Hz

|

|

Power

|

500W

|

|

Frequency

|

25kHz,Real-time display

|

|

Timer

|

1min~99H Can be set

|

|

Power regulation

|

1%—100%,1%Progressive

|

|

Temperature setting

|

0—300℃,1℃Progressive

|

|

Operating mode

|

Pulse、Time、continuous

|

|

LCD

|

Color touch screen, resolution: 800×480

|

|

Total length of ultrasonic horn

|

255mm

|

|

Material of Ultrasonic cutter

|

steel

|

|

Length of Cable

|

150-300cm

|

|

Theoretical cutting thickness

|

0~12mm

|

Product Description

It is suitable for cutting thick, thick and long materials that are inconvenient to set a cutting board. Such as raw rubber cutting, pipe cutting, frozen meat, candy, chocolate cutting, printed circuit boards, etc. In order to meet the needs of embossing cutting, a cylindrical flower wheel is added to the cutting chopping board, which can cut out endless patterns with low cost and high efficiency. This cutting method is suitable for the cutting of sheet materials, such as various labels, garment lace, fabric cutting, decorative sequin cutting, natural fibers, synthetic fibers, non-woven fabrics, synthetic resins, paper, film cutting, slitting, etc.

Output ultrasonic waves, and use the cutting knife to concentrate the ultrasonic energy into the cutting part of the material to be cut. Under the action of huge ultrasonic energy, this part is instantly softened and melted, and the strength is greatly reduced. Only a small amount of force is required to achieve the purpose of cutting the material.

Recommend Products

Hot Searches