- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

0 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Weier

-

Voltage:

-

as customer reqeust

-

Dimension(L*W*H):

-

20m*2m*2m

-

Weight:

-

17ton

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Field installation, commissioning and training, Field maintenance and repair service

-

Usage:

-

thermal forming,priting ,metal package

-

processed material:

-

APET, PETG, CPET

-

product:

-

apply single layer and three layes

-

chatacteristics:

-

exhaust screw design ,no need crystallization

-

raw material:

-

can use the new PET granules and PET recyle chips

-

characteristics:

-

high output ,durable

-

low energy cost:

-

adopt negative pressure drying system

-

Automatic Grade:

-

automatic

-

Power:

-

160kw

-

Certification:

-

CE ISO SG S

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

22:1

-

Screw diameter (mm):

-

65mm75mm

-

Screw Speed (rpm):

-

0 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Weier

-

Voltage:

-

as customer reqeust

-

Dimension(L*W*H):

-

20m*2m*2m

-

Weight:

-

17ton

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Field installation, commissioning and training, Field maintenance and repair service

-

Usage:

-

thermal forming,priting ,metal package

-

processed material:

-

APET, PETG, CPET

-

product:

-

apply single layer and three layes

-

chatacteristics:

-

exhaust screw design ,no need crystallization

-

raw material:

-

can use the new PET granules and PET recyle chips

-

characteristics:

-

high output ,durable

-

low energy cost:

-

adopt negative pressure drying system

-

Automatic Grade:

-

automatic

-

Power:

-

160kw

-

Certification:

-

CE ISO SG S

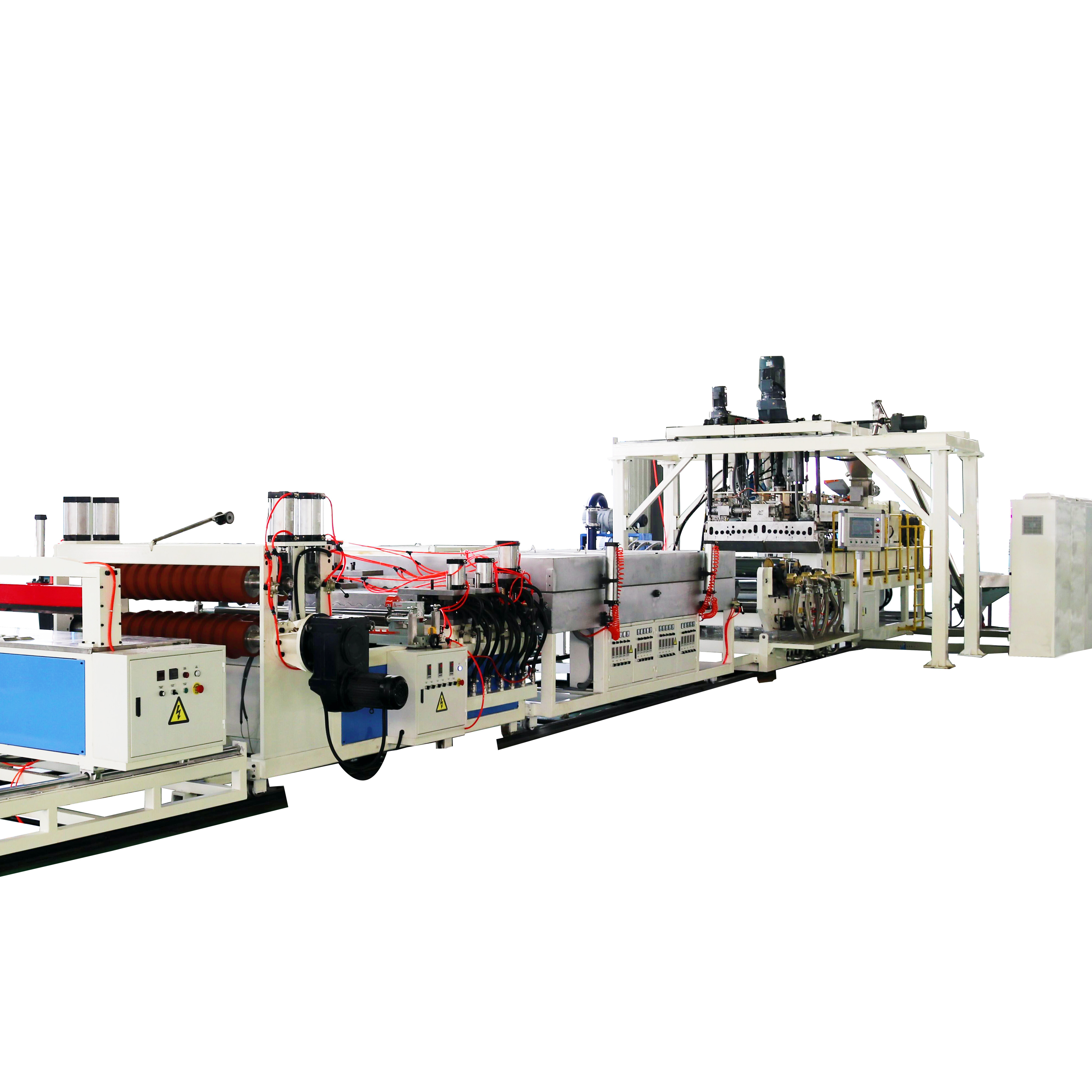

single layer and three layer PET sheet extrusion line

All three devices can be single, multi-layer co-extrudered sheet:

using multiple extruders co-extrusion technology to produce multi-layer coextrued composite PET, Such as APET, PETG, etc.

widely used in thermal forming, printing, metal packaging

with precision dispenser, evenly stratified and layers adjustable ratio.

Horizontal tablet structure, peration and maintenance more convenient.

Roll independent power, line speed and extruder speed synchronization control

The machine adopts PLC control, parameter setting, data and the feedback and alarm automation.

PET sheet extrusion line is developed by our company with compact structure, high and stable output, reasonable configuration and high automation is available for 100% reclaimed scrap material and can produce PET sheet used for packing material due to its advantages of air insulating, being free from other additives, cleanliness, good tenacity and ductibility, good reclaiming performance, etc. They are popular in the following packing and printing fields as medcine, food, electric appliance, toys, etc.

Specifications:

This sheet extrusion line is equiped 45 degree three-roller calander, with high performance vented extruder, die, screen change system, cooling rocket, haul-off unit, cutting unit and etc.

This kind of line is specially designed for producing APET, PETG and CPET single-layer and multi-layer sheet with thickness of 0.15mm to 1.5 mm and width of 500mm to 1500mm. It can be for produce PS,PP and PE sheet also.

The PET sheet is widely used in vary industry such as food package, electronic parts package, drugs package, medical equipment package, microwave stove plate, stationery package, etc.

The PET sheet is widely applying for packing industrial such as food, electronic parts, medicine, stationary and tool etc.

This sheet line is especially for APET, PETG single and multi-layer sheet. Thickness: 0.14mm to 1.5mm. Width: 500mm to 1500mm. Capacity: 200kg/h to 600kg/h. PP, PS, PE PLA are available on the same machine.

We are offering the whole line include crystallizer-dehumidifier, extruder, screen changer, gear pump, die ,3-roller calander, cooling rocket, haul-off unit, 2-station winding unit…etc. as a turn-key line.

| model | SHJ75/85 | 120/90/65 |

| material | APET PETG CPET | APET PETG CPET |

| product width | 650mm-1500mm | 650mm-1500mm |

| product thickness | 0.15mm-2mm | 0.15mm-2mm |

| extruder specification | 71.5mm,81.5mm | 120 90 65 |

| Max.capacity | 450kg/h-750kg/h | 450kg/h-750kg/h |

Machine details:

Eletrical cabinet

Extruder

Parallel double screw extruder is characterized by high output and good plasticization. The vacuum exhaust improves the quality of the product. It can process various sorts of plastic.

Metering pump

The meter pump with excellent quality alloy steel guarantees stable melting pressure and flow.

Mould

Moulds adopts high quality alloy steel and can make the material flow distributes evenly in the mouth mould with high active restricting device.

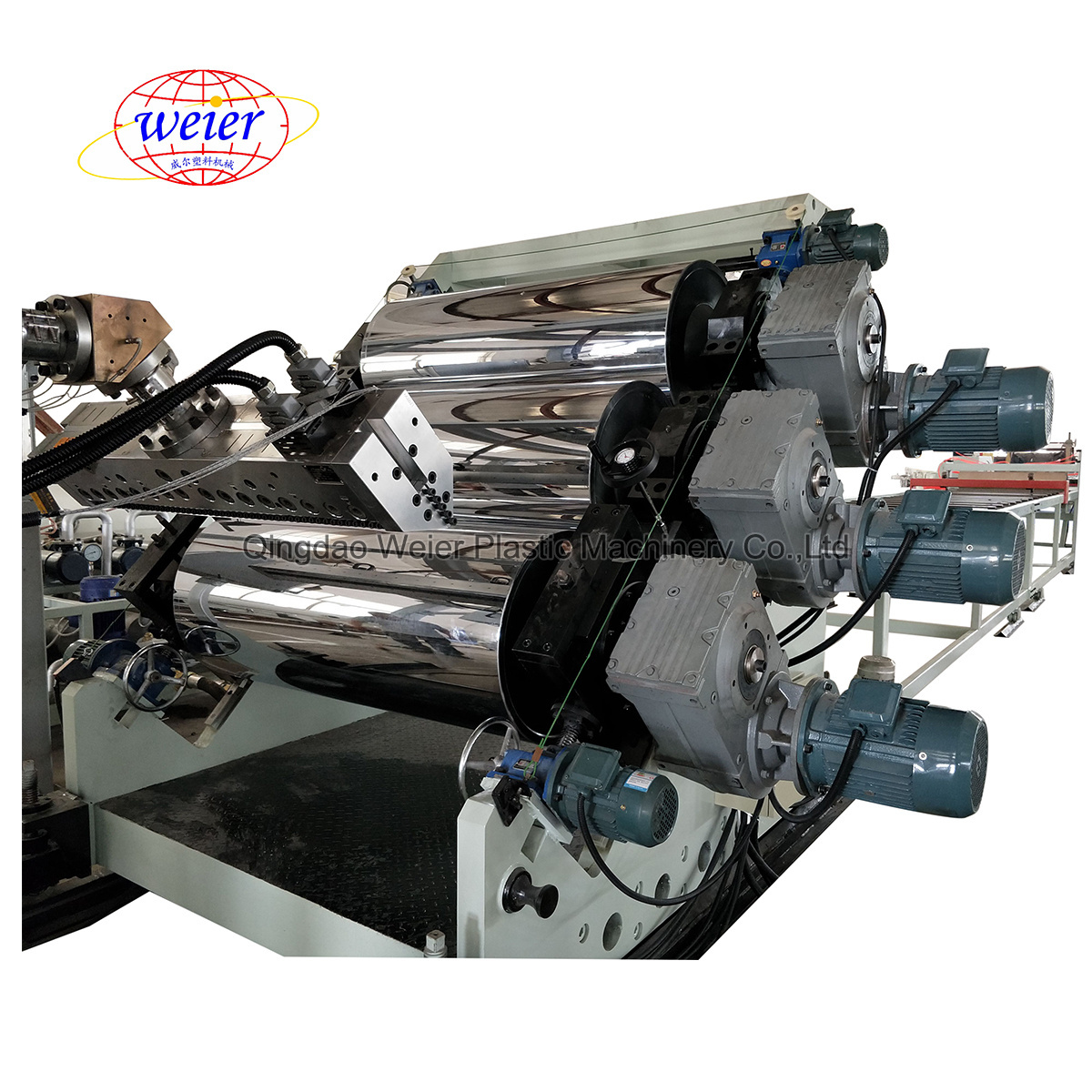

Three rolle calendar

Traction:

the cooling roller is of large diameter, low temperature and S type material discharge, It enlarges the impulsive cooling area and shortens the length of the production line. Rubber and steel rollers are equipped to realize traction, which guarantees the needed friction force, and the surface quality of the sheet as well.

Oven

Application

Company Qualificattion

Contact person:Emily

Phone number/ wechat/whatsapp:+86 15763965159

"Excellent Quality and Reasonable Price" is our company's quality policy;

"Honest Service and Win-win Cooperation" is our company's core concept.

we offer turn key project, with lifelong after sale service!

we have ready machines in factory for your test and visit! sincerely welcome all friends to visit our factory!

Its my honour to do something for you.