- Product Details

- {{item.text}}

Quick Details

-

Year:

-

2024

-

Weight (KG):

-

1000 KG

-

Working Area:

-

1300*2500mm

-

Laser Type:

-

Fiber

-

Fiber Laser Source:

-

Raycus or IPG

-

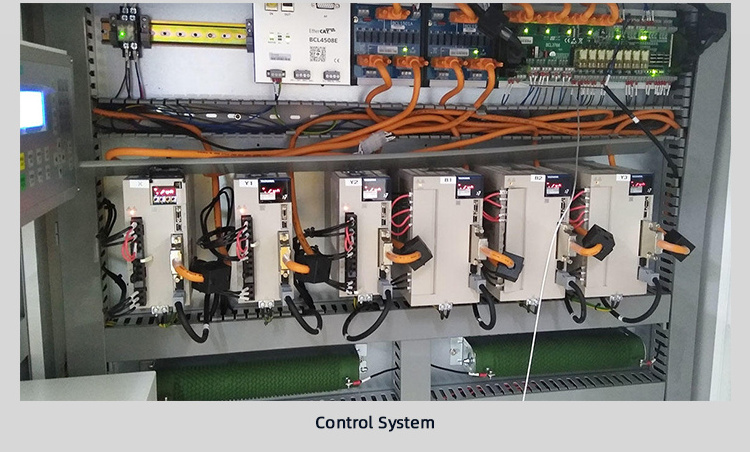

Control system:

-

AU3LECH

-

Special Function:

-

WIFI Remote Control

-

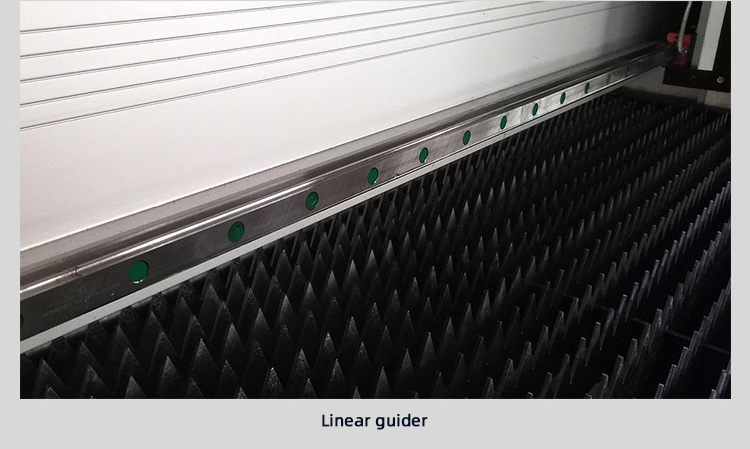

Guide:

-

Taiwan Hiwin or PMI

-

Leadscrew:

-

Grinding TBI

-

Cooling Type:

-

Water cooling

-

Gear box reducer make:

-

MOTOVARIO /SHIMPO

-

Chiller:

-

Tongfei chiller

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

LANSEN

-

Dimension(L*W*H):

-

3980*1010*1150mm

-

Year:

-

2024

-

Weight (KG):

-

1000 KG

-

Working Area:

-

1300*2500mm

-

Laser Type:

-

Fiber

-

Fiber Laser Source:

-

Raycus or IPG

-

Control system:

-

AU3LECH

-

Special Function:

-

WIFI Remote Control

-

Guide:

-

Taiwan Hiwin or PMI

-

Leadscrew:

-

Grinding TBI

-

Cooling Type:

-

Water cooling

-

Gear box reducer make:

-

MOTOVARIO /SHIMPO

-

Chiller:

-

Tongfei chiller

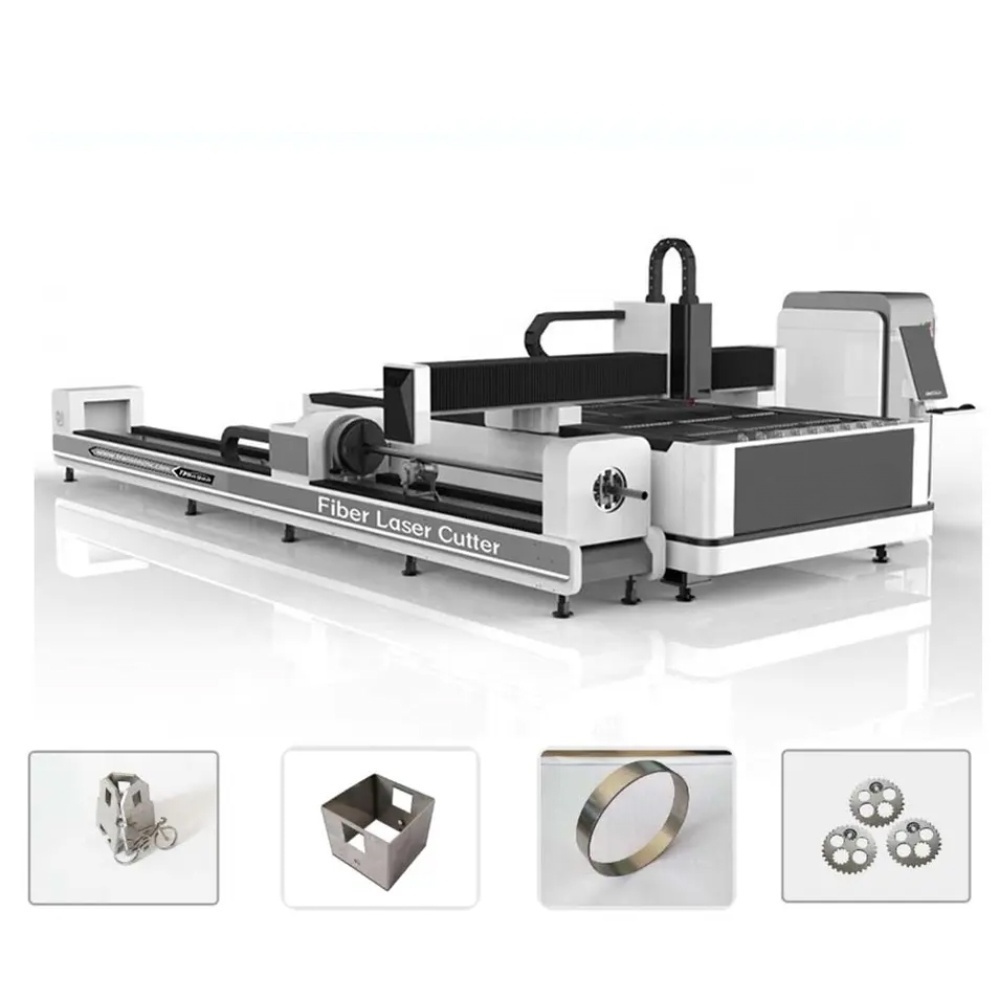

Product Description

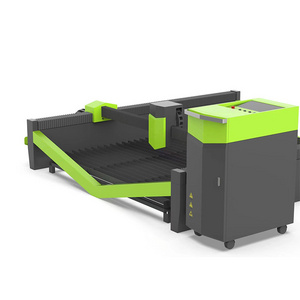

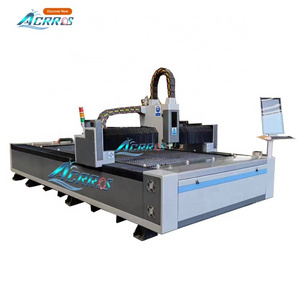

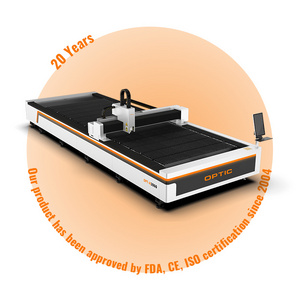

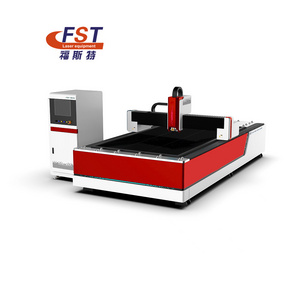

1000w 1500w 3000w metal iron sheets aluminium brass copper Fiber Laser Cutting machine

Widely used in sheet metal processing, aviation, aerospace, electronics, electrical appliances, automobile, food machinery,textile machinery, engineering machinery, precision parts, ships, metallurgy equipment, elevators, household appliances, craft gifts, tool processing, decoration, advertising, and other fields.

Parameters

|

Model

|

LF1325 Fiber Laser Cutting Machine

|

|

Fiber laser

|

RAYCUS 1500W

|

|

Cutting Head

|

Au3lech

|

|

Servo motor

|

YASKAWA for X ,Y

|

|

Electricals make

|

Schneider

|

|

Gear box reducer make

|

MOTOVARIO /SHIPMO

|

|

LM guide

|

PMI /HINWIN

|

|

Control system

|

Au3lech

|

|

Chiller

|

S&A chiller

|

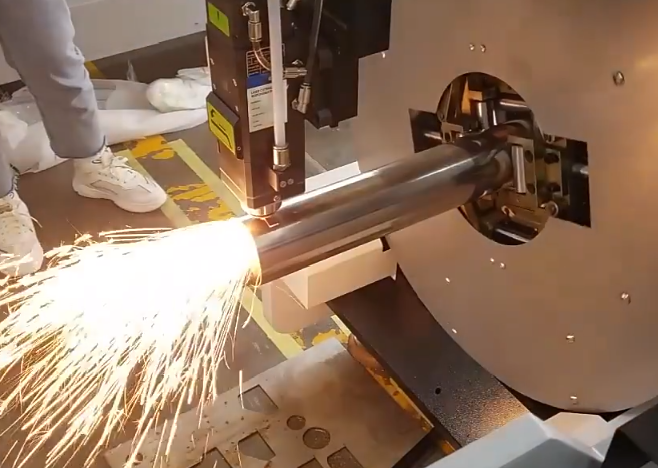

Metal Laser Cutting Machine Features:

1. It adopts advanced branded optical fiber laser core technology,good optical mode,stable performance.

2. High efficiency of photoelectric conversion,twice of domestic laser source.

3. Low heat of laser source,only needing 5P water cooling machine,saving electricity.

4. The gantry flying light path design,light operation,saving about 40% electricity than competitors.

5. Achieve a perfect cutting effect by only blowing compressed air during processing,which can largely reduce costs of auxiliary gas such as Oxygen.Nitrogen about thousand dollars.

6. Equipped with centralized lubrication system to make the machine run more stable.

7. Axial positioning accuracy of workbench: ≤±0.03mm/m

8. Repetitive positioning accuracy of workbench: ≤±0.03mm/m

The following speeds are for reference only and vary according to the thickness and hardness of the material

|

Power

|

Carbon steel

|

Stainless steel

|

Aluminium

|

Copper

|

|

1000W

|

24m/min

|

24m/min

|

10m/min

|

10m/min

|

|

2000W

|

28m/min

|

28m/min

|

25m/min

|

16m/min

|

|

3000W

|

35m/min

|

35m/min

|

43m/min

|

35m/min

|

Product Details

Application&Samples

LF1530 1325 Fiber Laser Cutting machine:

Professional used to cut thin sheet metal, in a variety of high quality 0.5-12 mm carbon steel sheet cutting, also cut stainless steel plate, aluminum alloy plate, galvanized sheet, electrolytic plate, silicon steel, titanium alloy, aluminum zinc plate and other metal materials.

Professional used to cut thin sheet metal, in a variety of high quality 0.5-12 mm carbon steel sheet cutting, also cut stainless steel plate, aluminum alloy plate, galvanized sheet, electrolytic plate, silicon steel, titanium alloy, aluminum zinc plate and other metal materials.

Packing & Delivery

Trade Terms: EXW, FOB, CNF, CIF, DDU, DDP, etc.

Supply Ability: 100 sets / Month

Port: Qingdao

Payment: T/T (Bank Transfer), western union, moneygram, PAYPAL payments for offline orders.

Packaging Detail: International standard plywood export box

Shipping: BY SEA, BY LAND, BY AIR OR BY EXPRESS

About Us

Warranty Terms:

----------------------------------------------------------------------------------------------

1. Installation

After the machine reach the buyer's site,the engineers from the seller are responsible for machine installation and commissioning by using the special tools under the help of the buyer. And then start training the workers. Tickets, hotel and food charge need to afford by buyers

2. Training

The common protection knowledge of laser safety

The basic principle of laser module and the structure of laser cutting machine

The operation skills of fiber laser cutting machine

Equipment operation and the application notice

Skills of equipment daily maintenance,laser module adjustment and spare parts replacement.

Training time is about 5 to 10 days.

3. After sales service

· 2 year warranty for the whole machine

· 2 years warranty for the fiber laser source

· Life-long maintenance

· In the warranty period,if it break down or some parts damaged(Except the human factors and the factors of force majeure),the seller should be responsible for repair for free,the parts need to be replaced will be provided from seller for free(Except the Consumable parts).

· After the warranty period expired,the buyer only need to pay the actual maintenance cost.

· Lansen will pay a return visit all customers for several times one year,and will provide technical support service anytime, and also provide spare parts anytime the buyer want.

Hot Searches