- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

3168*890*1830mm

-

Year:

-

2023

-

Power (kW):

-

30 kW

-

Weight (KG):

-

6500 KG

-

Name:

-

three roller rubber calender / rubber sheet machine

-

Processing type:

-

Rubber Machine

-

Control system:

-

PLC

-

Raw material:

-

rubber sheet

-

Machine Type:

-

S, I, L type

-

End product:

-

rubber sheet

-

Application:

-

Rubber Processing Machinery

-

Usage:

-

Rubber sheet

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

CGY

-

Voltage:

-

customer demand

-

Dimension(L*W*H):

-

3168*890*1830mm

-

Year:

-

2023

-

Power (kW):

-

30 kW

-

Weight (KG):

-

6500 KG

-

Name:

-

three roller rubber calender / rubber sheet machine

-

Processing type:

-

Rubber Machine

-

Control system:

-

PLC

-

Raw material:

-

rubber sheet

-

Machine Type:

-

S, I, L type

-

End product:

-

rubber sheet

-

Application:

-

Rubber Processing Machinery

-

Usage:

-

Rubber sheet

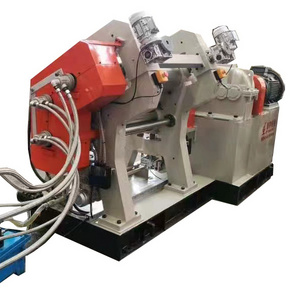

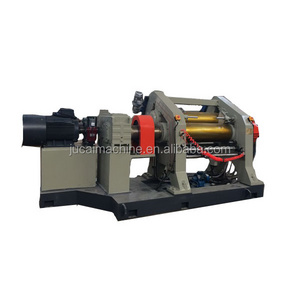

three roller rubber calender/rubber sheet machine

1. Application:

Lab calendar: Rubberizing and fractioning of textile material, rubberizing of wirecord fabric, sheet, and counter plate(embossed) of rubber material, separation of fabric and film, as well as joint of multi-layer laminate film.

2. General design:

It mainly contains roller, rack, backplane, adjustment, device, transmission system, roller temperature control device, security device, lubricating device, etc.

Small threeroll calender is miniaturized rolling forming units, with low energy consumption, a small amount of raw materials and other characteristics, suitable for laboratory use or small-scale production.

3. Features:

A - The rolls are made of chilled cast iron with vanadium and titanium alloys. The roll face is hard and anti-wear. To heat up or cool down, the rolls are either circumferentially drilled or centrally bored so as to make temperature well proportioned on the roll surface.

B - The rolls are arranged in I forms. The upper rolls have roll cambers that can eliminate bending impact on rolls during working process. Thus, it is possible to make products with same thickness along axial direction.

C - The transmission system adopts a hard facing gear reducer, which has a compacted structure with higher transmission efficiency, lower noise and longer service life.

D - The machine is equipped with emergency device. When an emergent accident occurs, the calendar will be immediately stopped to open the roll space so as to protect the operator and equipment.

4. Advantages:

Three roller linear guide rails, roll up and down times of the cylinder using compression, effectively guarantee the accuracy of the sheet size .

Super mirror calender rolls and doubleloop temperature control system can precisely control the temperature of three rollers, it has distinct advantages in forming crystalline material .

Adopt international famous brand frequency controlled variable speed motor and gear to ensure calender roll speed, winding speed extrusion speed to adapt to changes.

High performance safety pull switch, you can turn off the power in either direction, to ensure the safety of the operator and the machine.

Parameter of three-roll rubber calender

|

Application material |

LDPE,HDPE, PP, PS, ABS, PC |

|

Main motor power |

1.1KW for pull roll,1.5KW for other two rolls |

|

Material appliable: |

Plastic and rubber |

|

Sheet thickness range |

0.2-2mm |

|

Sheet widt h range |

0- 230 mm |

|

Roller of calender |

Ø120mm, width 250mm |

|

Distance between rolls |

0-5mm,Adjustable |

|

Roll quantity |

3 |

|

Diameter of roll |

120mm |

|

Length of roll |

250mm |

|

nip range |

0-5mm(adjustable) |

|

linear speed |

0.5-19m/min(continuously viable) |

|

Pull roll speed: |

0.5-20m/min(continuously viable) |

|

Max. Roll Temperature. |

180°C |

|

Overall size:(L×W×H) |

825×700×1400mm |

|

Safety standard: |

CE certificate |

|

Emergency stop: |

Automatic fault shutdown and manual emergency shutdown

|

Machine Pictures: