- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

7100*2250*2400mm

-

Voltage:

-

Customize

-

Power:

-

18.9kw/h

-

Weight (KG):

-

12000

-

Raw material:

-

Biomass Wastes

-

Product name:

-

Biomass Carbonization Furnace

-

Final product:

-

Charcoal Bio-char

-

Function:

-

Wood Biomass Charcoal Making

-

Heating source:

-

Energy Recycle

-

Capacity:

-

50-100kg/h

-

Color:

-

Customer Required

-

Fuel:

-

Biomass Gas&Electricity

-

Application material:

-

Waste

-

Carboniztion type:

-

Continuous Air Flow Pyrolysis

Quick Details

-

Place of Origin:

-

Henan, China

-

Marketing Type:

-

New Product 2023

-

Brand Name:

-

Mingjie

-

Dimension(L*W*H):

-

7100*2250*2400mm

-

Voltage:

-

Customize

-

Power:

-

18.9kw/h

-

Weight (KG):

-

12000

-

Raw material:

-

Biomass Wastes

-

Product name:

-

Biomass Carbonization Furnace

-

Final product:

-

Charcoal Bio-char

-

Function:

-

Wood Biomass Charcoal Making

-

Heating source:

-

Energy Recycle

-

Capacity:

-

50-100kg/h

-

Color:

-

Customer Required

-

Fuel:

-

Biomass Gas&Electricity

-

Application material:

-

Waste

-

Carboniztion type:

-

Continuous Air Flow Pyrolysis

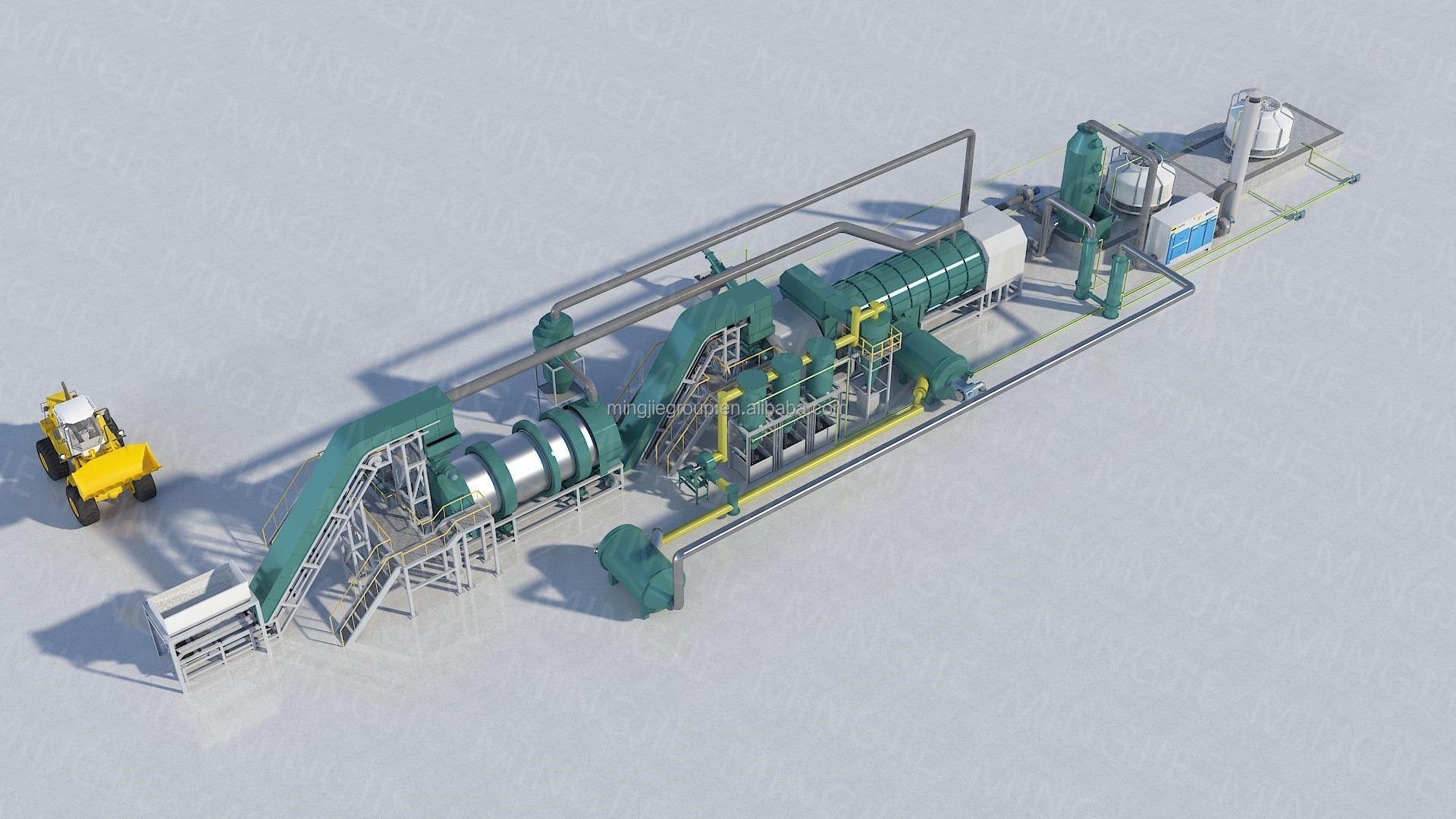

Product Overview

What is the carbonization?

Biomass carbonization refers to the thermal degradation process of biomass under the environment of high temperature without oxygen, in which volatiles are released and carbon is enriched. The carbonized product is biochar/charcoal, which can be used as soil conditioner or fuel.

Common Available raw material

Coconut Shell

Corn Straw

Cotton stem

Rice Husk

Woody waste

Municipality Sludge

PRODUCT SPECIFICATIONS

|

Model

|

MJT-500

|

MJT-1000

|

MJT-2000

|

MJT-3000

|

|||

|

Reactor Structure

|

Dual Cylinder

|

Dual Cylinder

|

Dual Cylinder

|

Dual Cylinder

|

|||

|

Input Capacity

|

300-500KG/H

|

800-1000KG/H

|

1500-2000KG/H

|

2500-3000KG/H

|

|||

|

Feedstock size

|

<20mm

|

<20mm

|

<20mm

|

<20mm

|

|||

|

Feedstock moisture

|

<15%

|

<15%

|

<15%

|

<15%

|

|||

|

Charcoal output ratio

|

28-35%

|

28-35%

|

28-35%

|

28-35%

|

|||

|

Working Method

|

Fully Continuous

|

Fully Continuous

|

Fully Continuous

|

Fully Continuous

|

|||

|

Fuel Consumption

|

35-50m³ Natural Gas for initial Heating

|

40-60m³ Natural Gas for initial Heating

|

60-80m³ Natural Gas for initial Heating

|

80-100m³ Natural Gas for initial Heating

|

|||

|

Land required

|

L35*W12*H6m

|

L35*W12*H7m

|

L45*W15*H7m

|

L45*W15*H7m

|

|||

|

Final product

|

Charcoal/Biochar, Tar&Wood Vinegar, Syngas

|

|

|

|

|||

Final Product & Application

Biochar/Charcoal

1. Used as soil conditioner, carbon sequestration, improve the quality of soil

2. Used as fuel for industry heating and cooling or BBQ

3. Can be reprocessed into activated carbon, widely used in the smelting, chemical fields.

Wood vinegar & tar

Widely used as a crop insecticide, make leaf surface fertilizer

Syngas

1. Can be recycled to heat the carbonization host.

2. By this way, you can reduce a lot of fuel costs.

FEATURES AT A GLANCE

Machine character

This equipment adopts inner & outer double-layer cylinder, fully 304 stainless steel, inner heating with waste heat, used for

pre-drying treatment, the whole machine adopts double-return heating structure, users are highly praised for their use.The heat utilization rate of this equipment is higher, the material not contact with flue gas, and is not polluted by hot air. Compared with the single-layer external heating structure, the heat utilization rate is more than double. The thermal efficiency of thee quipment is 70%~90%. It has good energy-saving effect. Modular design is convenient and reliable to install, low installation cost for users, simple operation, safety and reliability.

pre-drying treatment, the whole machine adopts double-return heating structure, users are highly praised for their use.The heat utilization rate of this equipment is higher, the material not contact with flue gas, and is not polluted by hot air. Compared with the single-layer external heating structure, the heat utilization rate is more than double. The thermal efficiency of thee quipment is 70%~90%. It has good energy-saving effect. Modular design is convenient and reliable to install, low installation cost for users, simple operation, safety and reliability.

Successful Project

Project in Japanese

Project in Iran

Project in Turkey

Customer Photos

CERTIFICATE

FAQ

Q1:

Feeding size and moisture requirement?

A1:

Size smaller than 20mm(8mm is best), moisture below 15%, otherwise shredder and dryer are required.

Q2:

What is the output quantity of the output?

A2:

Material moisture below 15%, Biochar:25-33%,tar:2-4%, wood vinegar:4-8%, gas:60-65%

Q3:

What temperature shall be kept during the operation?

A3:

Usually, inner cylinder temperature is around 150 degree for preheating and further dewatering the carbonization started at 150 degree, and start to release the mixed gas,fully carbonization reaction required temperature is around 380-450 degree, furnace temperature 550-650 degree. Depend on the rawmaterial and required output biochar quality, the temperature could be higher.

Q4:

What is the lifespan of the machine?

A4:

The key part of the carbonization is reactor which is made of 304 stainless steel, the life could be more than 10 years.

Hot Searches