- Product Details

- {{item.text}}

Quick Details

-

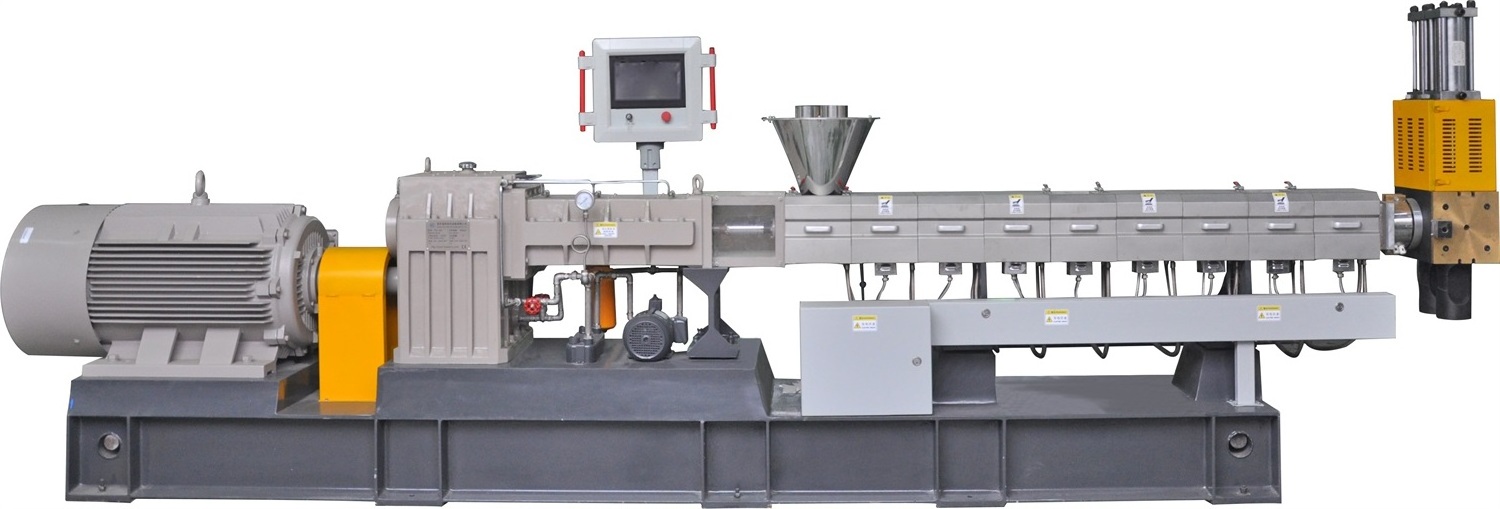

Screw diameter (mm):

-

62.4 mm

-

Place of Origin:

-

China

-

Brand Name:

-

HS

-

Voltage:

-

380v 420v or customized

-

Dimension(L*W*H):

-

capacity

-

Power (kW):

-

90

-

Weight:

-

4T

-

Output (kg/h):

-

250 - 350

-

Certification:

-

CE SGS TUV

-

Diameter:

-

62.4mm

-

L/D:

-

32-64

-

speed:

-

600r/min

-

Motor power:

-

90kw

-

Torque:

-

716N.m

-

Motor Brand:

-

Simens or WNM

-

Inverter Brand:

-

ABB

-

Motor pole:

-

four-pole motor

-

Automatic Grade:

-

semi-automatic

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

32-64

-

Screw Material:

-

w6mo5cr4v2

-

Screw diameter (mm):

-

62.4 mm

-

Place of Origin:

-

China

-

Brand Name:

-

HS

-

Voltage:

-

380v 420v or customized

-

Dimension(L*W*H):

-

capacity

-

Power (kW):

-

90

-

Weight:

-

4T

-

Output (kg/h):

-

250 - 350

-

Certification:

-

CE SGS TUV

-

Diameter:

-

62.4mm

-

L/D:

-

32-64

-

speed:

-

600r/min

-

Motor power:

-

90kw

-

Torque:

-

716N.m

-

Motor Brand:

-

Simens or WNM

-

Inverter Brand:

-

ABB

-

Motor pole:

-

four-pole motor

-

Automatic Grade:

-

semi-automatic

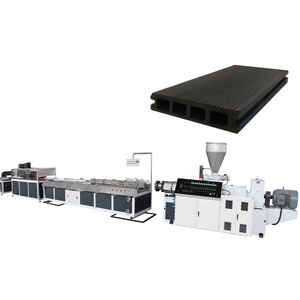

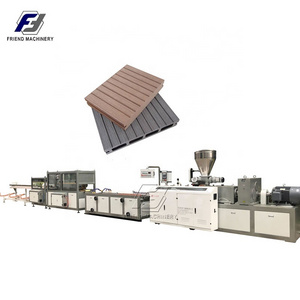

wood plastic composite granules WPC plastic wood pellet making machine

Application: cation:

The main materials of wood plastic are divided into two major categories: PE wood plastic and PVC wood plastic, using PE, PP andPVC, etc., instead of the usual resin adhesive, and more than 35% -70% of wood flour , rice husk, straw and other waste plant fibers are mixed into new wooden materials, and then subjected to plastic processing technology such as extrusion, molding, injection molding, etc., to produce plates or profiles, mainly used in building materials, furniture, logistics and packaging industries.

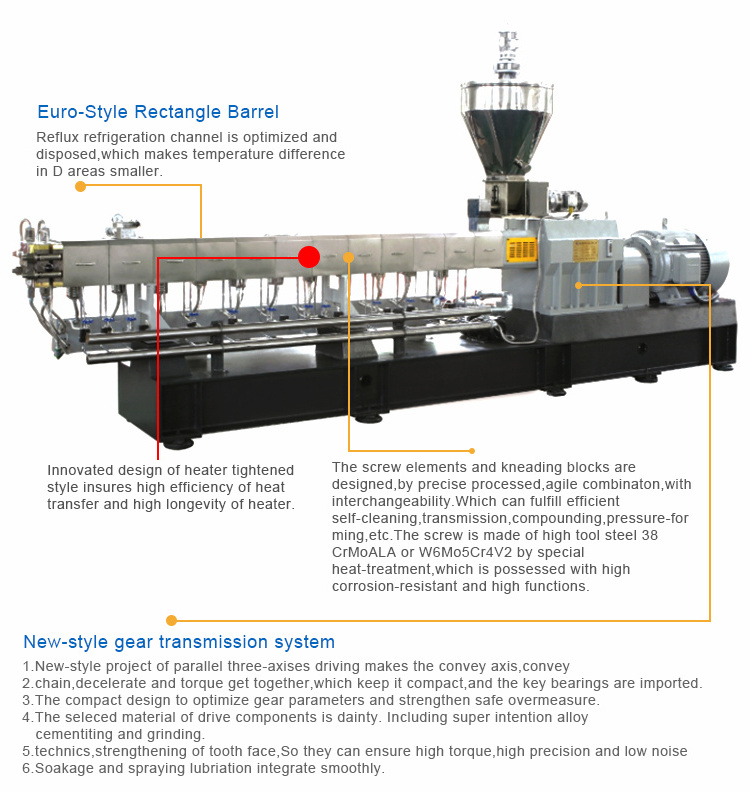

Technical Date: c

|

Mode |

Diameter (mm) |

L/D |

speed (r/min) |

Motor power (kw) |

Torque (N.m) |

Capacity (kg/h) |

|

TSE-20 |

22 | 32-44 | 600 | 5.5 | 43 | 0.5-10 |

|

TSE-30B |

31 | 32-48 | 600 | 15 | 119 | 5-40 |

|

TSH-35B |

35.6 | 32-52 | 600-800 | 15-22 | 119 | 30-70 |

|

TSE-40B |

41 | 32-52 | 600 | 45-55 | 437 | 90-150 |

|

TSH-40B |

41 | 32-52 | 600 | 45-55 | 437 | 150-220 |

|

TSE-5 0 B |

50.5 | 32-52 | 500 | 45-55 | 430 | 180-270 |

|

TSH-52B |

51.5 | 32-60 | 600 | 90-132 | 682 | 270-400 |

|

TSE-65B |

62.4 | 32-64 | 600 | 90 | 716 | 250-360 |

|

TSH-65B |

62.4 | 32-64 | 600-800 | 110-160 | 875 | 350-500 |

|

TSE-75B |

71 | 32-64 | 600 | 132 | 1050 | 350-500 |

|

TS H -75 B |

71 | 32-64 | 600-800 | 200-250 | 1365 | 600-800 |

|

TSE-95B |

93 | 32-64 | 600 | 315 | 2560 | 800-1200 |

|

TSH-95B |

93 | 32-64 | 600-800 | 400-450 | 2506 | 1200-1600 |

|

TSE-135 |

133 | 32-64 | 500 | 550 | 7162 | 1500-2250 |

Our Qualification

Nanjing Haisi Extrusion Equipment Co.,Ltd is a high-tech manufacturing company with 15 years experience in plastic making field. Our company is a professional manufacturer of granulating extruders for coloring/dyeing, filling masterbatch production, as well as plastic modification and compounding , plastic recycling. Company is in strict accordance with CE and ISO9001 quality certification system for production management. Surely you will also get professional machines and characteristic services here.