- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

FANTAI

-

Voltage:

-

380v 50hz

-

Power:

-

5.5kw

-

Dimension(L*W*H):

-

8.5*1*1.5m

-

Weight:

-

2800 kg

-

Hydraulic cutting:

-

1 set

-

Usage:

-

Construction Building Material

-

Material Thickness:

-

0.6-1.2mm

-

Raw material:

-

PPGI PPGL GI GL

-

Keywords:

-

Normal+Normal Roll Forming Machine

-

Decoiler:

-

3 Ton Manual

-

Shaft material:

-

40Cr

-

Material:

-

Cold-rolled Coil

-

Roller Station:

-

12 Stations+ Straightening Rollers

Quick Details

-

Work Pressure:

-

10-12mpa

-

Production Capacity:

-

10 m/min

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

FANTAI

-

Voltage:

-

380v 50hz

-

Power:

-

5.5kw

-

Dimension(L*W*H):

-

8.5*1*1.5m

-

Weight:

-

2800 kg

-

Hydraulic cutting:

-

1 set

-

Usage:

-

Construction Building Material

-

Material Thickness:

-

0.6-1.2mm

-

Raw material:

-

PPGI PPGL GI GL

-

Keywords:

-

Normal+Normal Roll Forming Machine

-

Decoiler:

-

3 Ton Manual

-

Shaft material:

-

40Cr

-

Material:

-

Cold-rolled Coil

-

Roller Station:

-

12 Stations+ Straightening Rollers

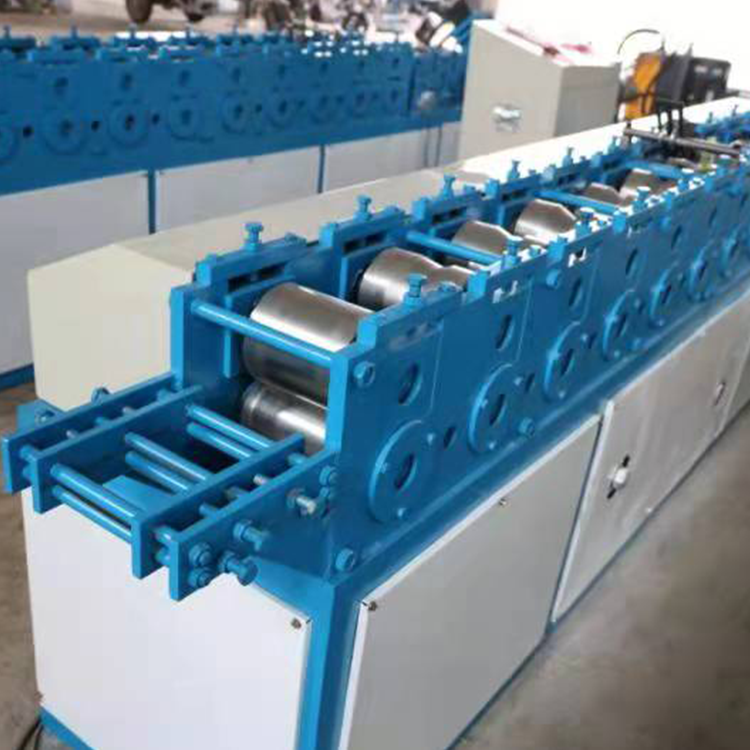

Products Description

Our

C D UD Profile Sheet Cold Roll Forming Machine

is customized, we will design and produce the machine as your personal requirements.

The metal sheet roll forming machine is the popular machine that used in many palace , it gets praise from all customers because of advantage of beautiful end products, easy operate and strong wind resistance.

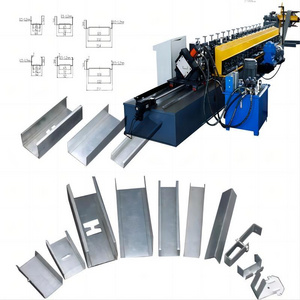

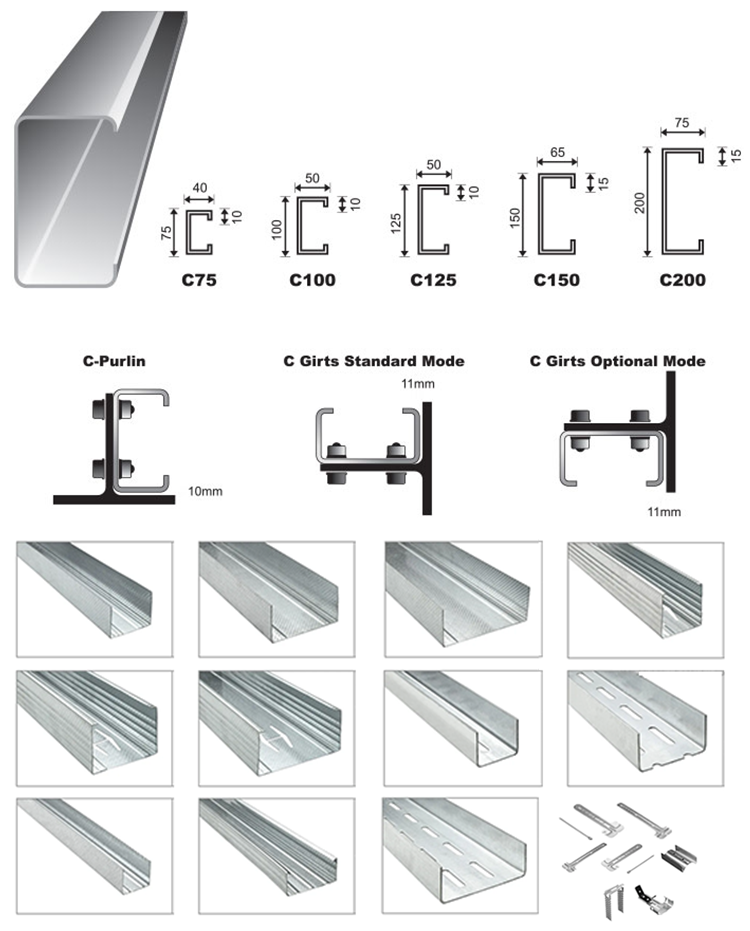

Drywall Profile Stud and Track Forming Machine is designed to produce non load-bearing partitions in galvanized steel. It has a wide range of applications, from small and residential needs to large commercial and industrial aplications. Using start-stop technology, these machines can make 8 profiles that make up all the basic metal frames for plasterboard walls and ceilings: three different with supporting stud and track (e.g. 48, 70 and 90mm), a ceiling profile (F530) and the relative wall angle. this metal stud machine can produce different sizes of studs and tracks, for example, 50/75/100 ( CU, UW, CW)

|

Voltage

|

380v 50hz

|

Equipment forming

|

hydraulic shearing

|

|

Power

|

5.5kw

|

Hydraulic oil

|

46# hydraulic oil

|

|

Dimension(L*W*H)

|

8.5*1*1.5m

|

Gear oil

|

18# hyperbolic gear oil

|

|

Weight

|

2800kg

|

Motor explosion-proof grade

|

ExdIICT4

|

|

Warranty

|

1 Year

|

Motor protection class

|

IP55

|

|

Key Selling Points

|

Automatic

|

Ordinary hydraulic pump station

|

1 set

|

|

Equipment feeding direction

|

left in right out

|

Usage

|

Steel Construction

|

|

Voltage parameters

|

380/50/60

|

Hydraulic cutting

|

1 set

|

Our partition wall keel equipment counter adopts Japanese Omron, the counter bracket adopts double spring force and the wheel adopts rubber material to ensure that the wheel is in close contact with the product, which solves the problem of inaccurate product size and satisfies the customer's installation process In the need for precise dimensions.

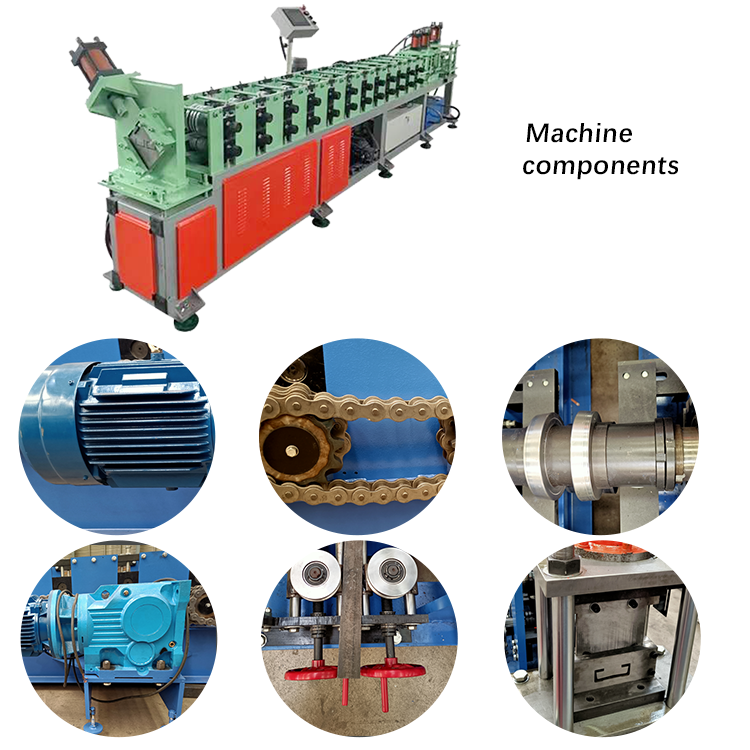

Details Images

Product Display

Why Choose Us

|

Service

|

|

|

|

|

||||

|

* Quality Control

|

We have independent QC departments both in the company and factories which strictly control the quality of each process to enable our production lines to reach Chinese National Standards, even International Standards.

|

|

|

|

||||

|

* Technology R&D

|

We have R&D centers and innovative designing teams for different kinds of production lines

|

|

|

|

||||

|

* After Sale Service

|

Warranty period 1 year , after this period , we are willing to give help if customer needs accessory . The real cooperation will not end at the delivery . we believe that satisfied after sale service means a lot.

|

|

|

|

||||

|

* Inspected by the Sellers

|

After completing the manufacturing and assembling of the equipments, we will test the machines and commissioning in the workshop.

|

|

|

|

||||

|

* Inspected by the Buyers

|

After confirmation of a sound work of the line, we will invite our customer to send their representatives to inspect the production lines in our factories.

|

|

|

|

||||

1.Good quality: We have a professional designer and experienced engineer team.And the raw material and accessories we use are good.

2.Good service: we provide the technical support for whole life of our machines.

3.Guarantee period: within one year since the date of finishing commissioning. The guarantee covers all the electric, mechanic and hydraulic parts in the line except for the easy-worn parts.

4.Easy operation:All machine cotrolling by PLC computer controlling systerm.

5.Elegant apperance:Protect the machine from rust and the painted colour can be customized

6.Reasonable price:We offer the best price in our industry.

Recommend Products

Company

FAQ

1. Does one machine can only produce one style panel profile?

Not exactly.For wider and double layer making machine. It can produce more than 6 kinds of panels.

2. Do you have after sales support?

2. Do you have after sales support?

Yes, we are happy to give advice and we also have skilled technicians available across the world.We need your machines running in order to keep your business running.

3. What can you do if the machine broken?

3. What can you do if the machine broken?

Our machine's warranty period is 12months,if the broken parts can't repair,we can send the new parts replace the broken parts freell,but you need pay the express cost yourself.if after warranty period,we can through negotiationfor to solve the problems and we supply the technical support for the whole life of the equipment.

4. Can you be responsible for transport?

4. Can you be responsible for transport?

Yes,please tell me the destination port or address.we have rich experience in transport

Hot Searches