- Product Details

- {{item.text}}

Quick Details

-

Core Components:

-

Fiber laser source

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

KUNTAI

-

Dimension(L*W*H):

-

1200x700x1100

-

Year:

-

2023

-

Weight (KG):

-

250 KG

-

Product name:

-

laser cleaning machine

-

Application:

-

Metal Rust Oil Painting Removal

-

Cooling method:

-

Water Cooling

-

Scan width:

-

10-300mm

-

Function:

-

Metal Rust Surface Laser Cleaning

-

Cleaning Process:

-

Non-contact Laser Cleaning

-

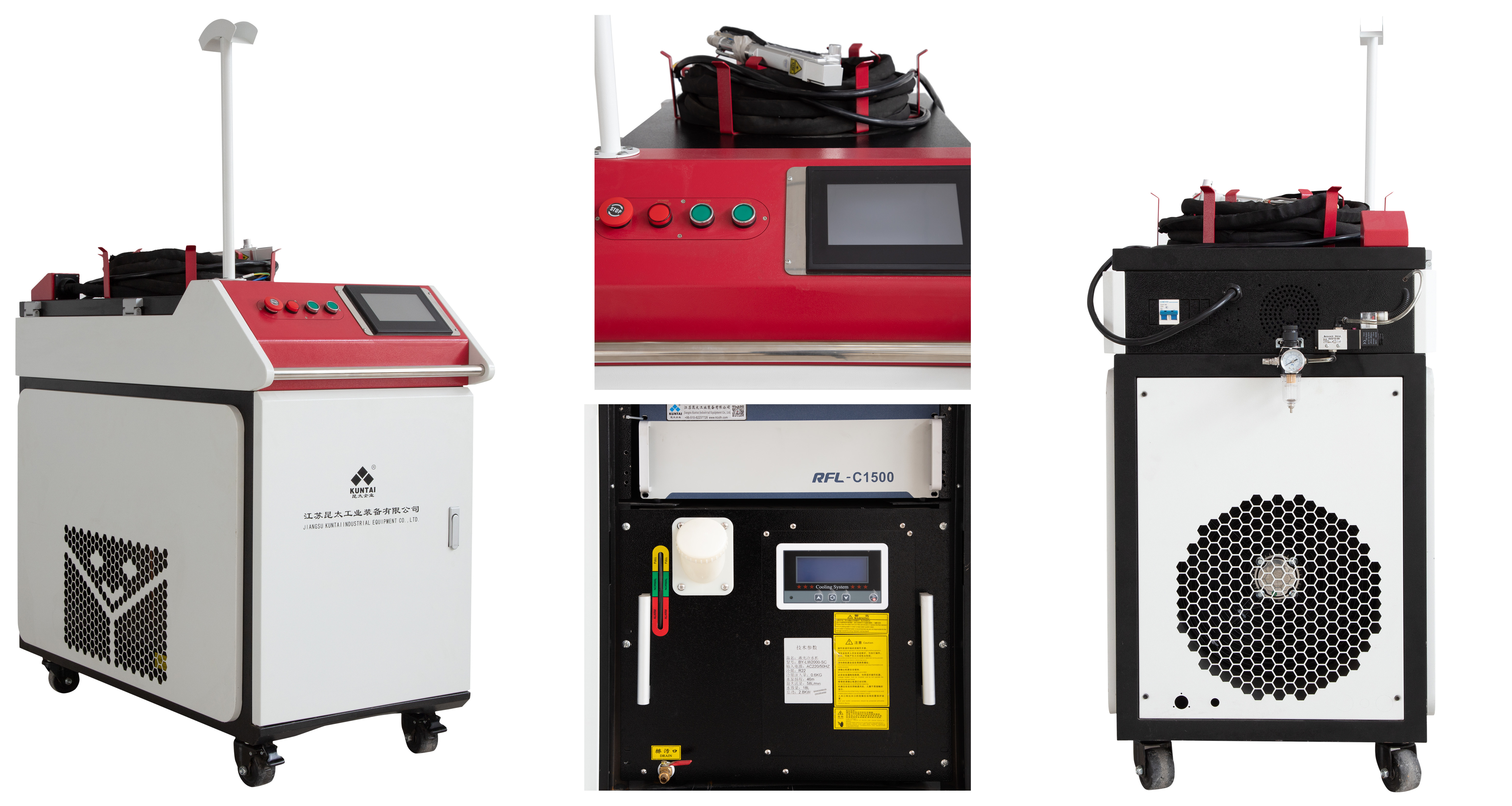

Laser Power:

-

1000W/1500W/2000W Optional

-

Advantage:

-

Eeasy Operate

-

Voltage:

-

220V-50Hz/380V-60Hz

-

Certification:

-

CE

Quick Details

-

Power:

-

3000W, 1500W, 1000W, 2000W

-

Laser Type:

-

Fiber Laser

-

Laser Source Brand:

-

RAYCUS

-

Core Components:

-

Fiber laser source

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

KUNTAI

-

Dimension(L*W*H):

-

1200x700x1100

-

Year:

-

2023

-

Weight (KG):

-

250 KG

-

Product name:

-

laser cleaning machine

-

Application:

-

Metal Rust Oil Painting Removal

-

Cooling method:

-

Water Cooling

-

Scan width:

-

10-300mm

-

Function:

-

Metal Rust Surface Laser Cleaning

-

Cleaning Process:

-

Non-contact Laser Cleaning

-

Laser Power:

-

1000W/1500W/2000W Optional

-

Advantage:

-

Eeasy Operate

-

Voltage:

-

220V-50Hz/380V-60Hz

-

Certification:

-

CE

Specification

|

Product name

|

Laser cleaning machine

|

|

Laser type

|

Fiber laser

|

|

Laser wavelength

|

1080 ± 5nm

|

|

Power

|

1000W / 1500W / 2000W

|

|

Pulse frequency

|

10-50 KHz

|

|

Scan width

|

10-300mm

|

|

Power supply

|

220V-50Hz/380V-60Hz

|

|

Cooling method

|

Water cooling

|

|

Working temperature

|

5 - 40℃

|

|

Application

|

Metal Rust Oil Paint Removal

|

|

Cleaning Type

|

Non-contact Laser Cleaning

|

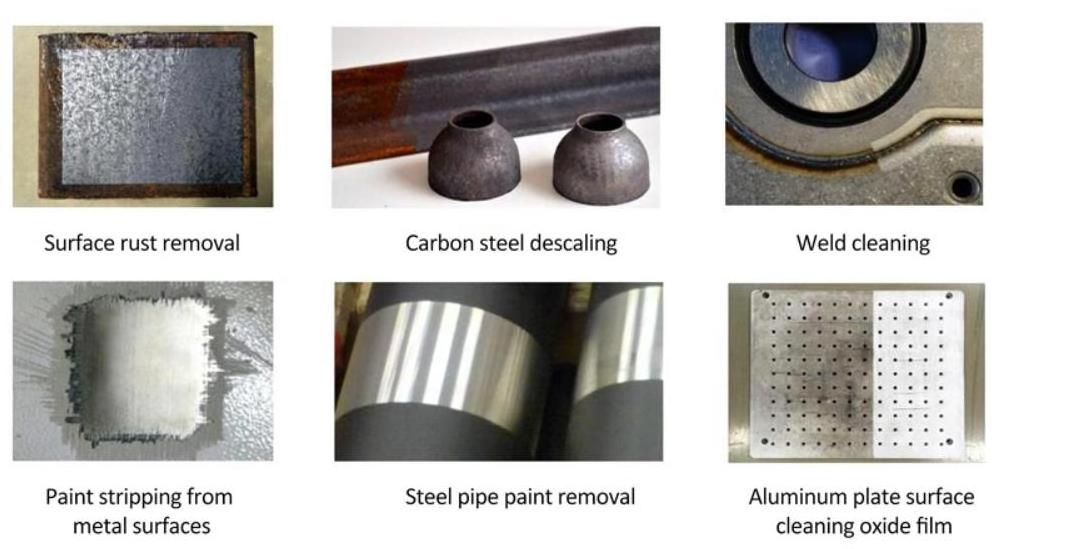

Product Description

The handheld fiber laser cleaning machine is a new generation of high-tech products for surface cleaning. It is very easy to install and operate. The machine needs no chemical reagent, no medium, dust-free and water-free cleaning, with the advantages of automatic focus, crank surface cleaning and high surface cleanliness. Laser cleaning machine can remove the object surface resin, the paint, the oil pollution, stains, dirt, rust, coatings and oxide coatings. It is widely used in the industry, covering ships, steam repairs, rubber molds, high-end machine tools, track and environmental protection.

Applicable Industries

It is suitable for the cleaning of the rust layer, thick-layer paint, deep oil stain, rough surface and weld cleaning, which will not affect the surface of the substrate. The efficiency is very high.

* Marking

* Mold cleaning

* Weapons and equipment cleaning

* Aircraft old paint removal

* The cleaning of building external wall

* The cleaning in the electronics industry

* Precisely degreasing in the precision machinery industry

* Pipe cleaning in nuclear power plant reactors

* Marking

* Mold cleaning

* Weapons and equipment cleaning

* Aircraft old paint removal

* The cleaning of building external wall

* The cleaning in the electronics industry

* Precisely degreasing in the precision machinery industry

* Pipe cleaning in nuclear power plant reactors

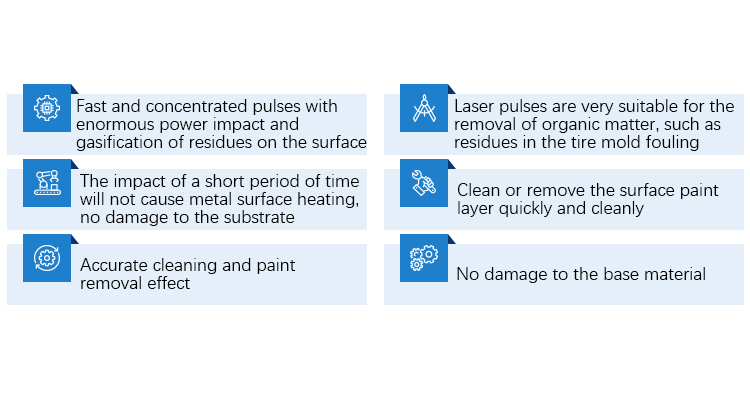

Advantages

Laser cleaning technology emerged as a green and environmentally friendly cleaning method. Compared with traditional industrial cleaning, it has the following advantages

1. No consumables, no chemical pollution, no noise, energy saving and power saving

2. No contact, no grinding, no stress, minimal damage to the substrate

3. Optical fiber transmission, movable operation, c

an clean hard-to-reach parts

4. It can realize rapid cleaning of heavy pollutants and high-speed cleaning of light pollutants

5. Maintenance-free, low operating cost

|

Comparison

|

Laser Cleaning

|

Chemical Cleaning

|

Mechanical Grinding

|

Dry Ice Cleaning

|

Ultrasonic cleaning

|

|

Cleaning Method

|

non-contact cleaning

|

contact cleaning

|

Abrasive contact cleaning

|

non-contact cleaning

|

Cleaning agent, contact cleaning

|

|

Harm to base material

|

None

|

Yes

|

Yes

|

None

|

None

|

|

Cleaning Efficiency

|

High

|

Low

|

Low

|

Mid

|

Mid

|

|

Consumable

|

Electricity Power

|

Chemical Detergent

|

Abrasive paper, grinder, abrasive stone

|

Dry Ice

|

Dedicated cleaning fluid

|

|

Cleaning result

|

Excellent

|

Medium, uneven

|

Medium, uneven

|

Good, uneven

|

Excellent, small area cleaning

|

|

Precision cleaning

|

Accuracy controllable, high precision

|

Uncontrollable, low precision.

|

Uncontrollable, medium precision.

|

Uncontrollable, poor precision.

|

Cannot specify cleaning range

|

|

Safety/Environment

|

No pollution

|

Chemical pollution

|

Dust pollution

|

No pollution

|

No pollution

|

|

Operation

|

Easy to operate, portable or automation optional.

|

Complicated process, higher technical requirement of the operator. Pollution prevention measures required.

|

Need more time & manpower. Pollution prevention measures required.

|

Easy to operate, portable or automatic.

|

Simple operation, but need to manually add consumables

|

|

Investment

|

High investment on machine. But no consumable, low maintenance cost

|

Low investment on machine. But expensive consumables

|

Medium investment on machine. High man-power cost.

|

Medium investment on machine. High consumable cost.

|

Low initial investment, medium cost of consumables

|

Product packaging

Recommend Products

Why Choose Us

FAQ

Q: I am not sure if this machine can work on my product or not, how do I choose?

A: We will help you choose the suitable machine and give you solution, you can tell us the material of product, shape of workpiece, marking position, marking content size, and marking depth requirement.

Q: Is this machine easy to operate, what should I do if I don't know how to use it?

A: We send installation and operation manual with machine, operation video, online training via Skype, Wechat, Whatsapp, phone conversation etc. are available. Staff training in our factory is free of charge, if needed, we can send our engineer overseas for training.

Q: If machine is out of order, what shall I do?

A: We provide one year warranty for machine, two years warranty for laser generator.

If find problem, please contact us, we will reply you within 24 hours and help you find out problem then figure it out. We provide lifelong maintenance and replacement parts.

Q: What are the interface language options of marking software?

A: The marking software interface language options are English, Korean, Japanese, Chinese simplified, Chinese traditional.

Q: Will the package be strong enough because it might be multi-way transportation.

A: We have three layers, for the inner layer, the machine is wrapped with waterproof shrink film. The outside layer is strong wooden case free of fumigation. Between these two layers, we will fill EPE foam, bubble bag, carboard and so on to avoid the machine damage by shaking.

Q: What is the delivery time?

A: Commonly the lead time is 5 working days after receiving payment. For customized machines and large quantity order, the lead time will be longer.

Q: What is the payment terms?

A: We accept payment by TT, LC, Paypal, Western Union, Mastercard, VISA, Cash, Alibaba trade assurance etc.

Hot Searches