- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

1g

-

Voltage:

-

208~415V

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Tandy

-

Dimension(L*W*H):

-

800x790x1900mm

-

Weight:

-

260 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

Semiautomatic powder auger dosing filling machine

-

Other name:

-

Semiautomatic powder screw filling packer

-

packing weight:

-

10-5000g

-

Control system:

-

PLC&Touch Screen

-

Material:

-

SUS304

-

filling speed:

-

40-120 times per min

-

Hopper:

-

Quick disconnecting hopper 50L

-

Keywords:

-

Fillng Machine

-

Function:

-

Automatic Filling Material

Quick Details

-

Machinery Capacity:

-

6000BPH

-

Packaging Material:

-

Plastic, Paper, Metal, Glass

-

Filling Material:

-

Other, Milk, Powder

-

Filling Accuracy:

-

1g

-

Voltage:

-

208~415V

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Tandy

-

Dimension(L*W*H):

-

800x790x1900mm

-

Weight:

-

260 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

Semiautomatic powder auger dosing filling machine

-

Other name:

-

Semiautomatic powder screw filling packer

-

packing weight:

-

10-5000g

-

Control system:

-

PLC&Touch Screen

-

Material:

-

SUS304

-

filling speed:

-

40-120 times per min

-

Hopper:

-

Quick disconnecting hopper 50L

-

Keywords:

-

Fillng Machine

-

Function:

-

Automatic Filling Material

High accuracy semiautomatic flavor powder packing helical dosing filling packer machine

Descriptive abstract of auger filling machine:

This type can do dosing and filling work. Due to the special professional design, so it is suitable to the fluidic or low-fluidity materials, like coffee powder, wheat flour, condiment, solid drink, veterinary drugs, dextrose, pharmaceuticals, powder additive, talcum powder, agriculture pesticide, dyestuff, and so on.

Main features of auger filling machine:

1. Stainless steel structure;Quick disconnecting or split hopper could be washed easily without tools.

2. Servo motor drive screw.

3. Weight feedback and proportion track get rid of the shortage of variable packaged weight for various proportion of different material.

4. Save the parameter of different filling weight for different materials. To save 10 sets at most.

5. Replacing the auger parts, it is suitable for material from super thin powder to granule.

|

Model |

TDCS-1A-22 |

TDCS-1B-321 |

TDCS-1B-423 |

|

Control system |

PLC & Touch Screen |

PLC & Touch Screen |

PLC & Touch Screen |

|

Hopper |

Quick disconnecting hopper 25L |

Quick disconnecting hopper 50L |

Split hopper 50L |

|

Packing Weight |

1 - 500g |

10 - 5000g |

10 - 5000g |

|

Packing Weight |

≤ 100g, ≤±2%; 100 – 500g, ≤±1% |

≤ 100g,≤±2%; 100 – 500g,≤±1%; ≥500g,≤±0.5% |

≤ 100g, ≤±2%; 100-500g, ≤±1%; ≥500g, ≤±0.5% |

|

Filling speed |

40 – 120 times per min |

40 – 120 times per min |

40 – 120 times per min |

|

Power supply |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

|

Total Power |

0.93 Kw |

1.4Kw |

1.4Kw |

|

Total Weight |

130kg |

260kg |

280kg |

|

Overall Dimensions |

800×790×1900mm |

1140×970×2200mm |

1140×970×2200mm |

Picture of auger filling machine:

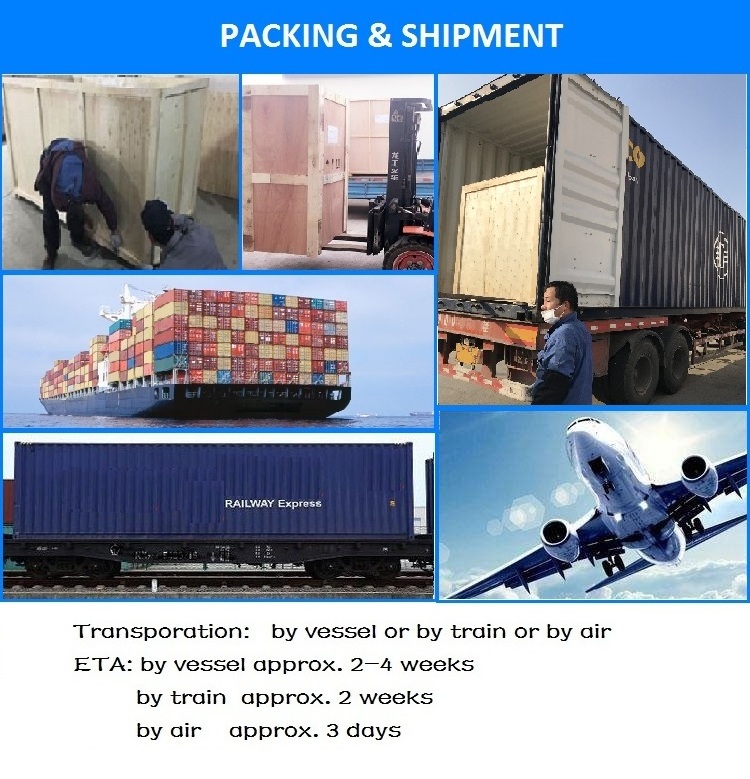

Packaging& Shipping