services. Products cover motorcycle accessories, LED lighting accessories, communication accessories, electrical accessories and so on.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

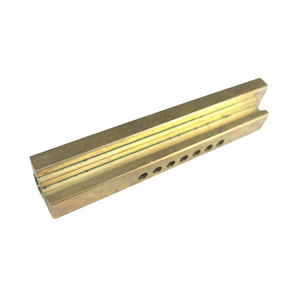

HRD, HRD- CNC product

-

Brand Name:

-

HRD

-

Material:

-

Aluminum alloy,alloy, copper, iron, stainless steel.SUS304.SUS316

-

Surface Treatment:

-

Electroplating, oxidation, sandblasting

-

MOQ:

-

1PCS

-

Tolerance:

-

±0.01mm

Quick Details

-

CNC Machining or Not:

-

Cnc Machining

-

Material Capabilities:

-

Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys

-

Place of Origin:

-

Guangdong, China

-

Model Number:

-

HRD, HRD- CNC product

-

Brand Name:

-

HRD

-

Material:

-

Aluminum alloy,alloy, copper, iron, stainless steel.SUS304.SUS316

-

Surface Treatment:

-

Electroplating, oxidation, sandblasting

-

MOQ:

-

1PCS

-

Tolerance:

-

±0.01mm

We Are The Metal Parts Manufacturing Experts

Our On-Demand Manufacturing Services

Our On-Demand Manufacturing Services

Huarong Da Technology delivers high-quality precision machining with an incredible range of manufacturing capabilities. We strive for uncompromising quality and take pride in our expert craftsmen– most with over 10 years experience–in handling every aspect of production from the initial design and planning process to the finishing and delivery of your specialized parts.

We focus on customer service at every stage of the casting process to ensure quality products, on-time delivery.

Customized Service

WHAT WE DO

Custom production includes mechanical part prototyping of all parts, tooling design and construction, volume processing, and any required post-production machining and part surface finishing.

Die Casting

We offer die casting services in a variety of materials that produce accurate and complex shapes. Die casting can produce a broad

range of parts with perfect finish and astonishing detail.

range of parts with perfect finish and astonishing detail.

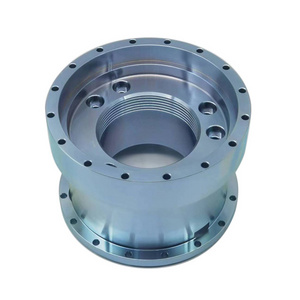

Precision CNC Machining

Fast and precise CNC machining through the use of state-of-the-art 3-axis and 5-axis equipment and lathes.

Precision CNC machining works with a variety of materials including metals, woods, acrylics, foams, and thermoplastics.

Sheet Metal and Stamping

We can supply sheet metals for most materials, including aluminum, hot-rolled steel, cold-rolled steel, carbon steel, stainless steel, copper, and galvanized steel. We can also provide circuit design and electronic components assembly services.

Metal Part Production

We provide full-service metal fabrication services, working with you from product research to manufacturing.

Plastic Injection

We provide plastics injection for all materials, such as PVC, PE, PP, PC, ABS, and Teflon.

Post Processing

We offer most post processing and product finishing services for die cast parts from our select partners.

Materials

Custom

We're your one-stop source for metalwork castings.

Stainless Steel

Aluminum alloy

Brass

Purple Copper

ABS

POM

PC

PMMA

Teflon

Surface Treatment

We use a variety of surface treatment, you have a variety of options

Anodizing

Brushing

Galvanized

Laser engraving

Plating

Polishing

Powder coating

Sandblasting

Silk printing

Products Description

|

Processing materials

|

Aluminium alloy: 5052 /6061/ 6063 / 7075/5083/2024 et al.

|

|

|

Copper products: 3602/2604 /H59 /H62/et al.

|

|

|

Stainless steel: 303 /304 /316/412 /et al

|

|

|

Alloy steel: carbon steel and die steel / steel 45#.: Cr2, acrylic plate.steel, Teflon, bakelite pieces, organic glass processing,

aluminumprofile, ABS,POM nylon pieces, such as a variety of commonly usedmaterials processing |

|

Product

|

CNC machining parts, precision CNC parts, CNC turning parts, CNCmilling parts,Metal parts.CNC parts,CNC machinery parts,

Mechanical components, Autoparts, Metal parts, |

|

Processing method

|

CNC machining,CNC turning,CNC milling, grinding,Drilling,Tappingand etc.

|

|

Finishing

|

Anodized, heat treatment, Black Oxide, Sandblasting, Nickel/Zinc/Chrome

|

|

Drawing format

|

STEP, STP, GIS, CAD, PDF, DWG, DXF etc or samples.

|

|

Tolerance

|

+/-0.01mm ~ +/-0.05mm

|

|

Surface roughness

|

Ra 0.1~3.2

|

|

Inspection

|

Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier, CMM. Depth Caliper Vernier, Universal

Protractor,Clock Gauge, Internal Centigrade Gauge. |

|

Capacity

|

CNC turning work range: φ0.5mm-φ150mm*300mm. CNC milling work range: 510mm*1020mm*500mm.

|

|

Application

|

Aerospace, Automotive, Medical, telecommunications, electronic,packingSensors,Optical instruments, computers,Motorcycles etc.

|

About us

Our commitment to quality, service and technology allows us to consistently meet your needs and expectations. We specialize in providing OEMs with quality castings at competitive prices. We will work with your team from concept to casting with on-time delivery.

Huarongda was founded in 2010, the factory is located in Dongguan, the Marketing Department is located in Shenzhen, is a design, production, processing, sales, service as one of the industry and trade company, we have more than 10 years of rich experience.

Provide mold design and manufacturing, die casting processing.

CNC and lathe machining, aluminum extrusion services, stamping, sheet metal machining and surface treatment and all related

services. Products cover motorcycle accessories, LED lighting accessories, communication accessories, electrical accessories and so on.

services. Products cover motorcycle accessories, LED lighting accessories, communication accessories, electrical accessories and so on.

Why Choose Huarong Da Technology for Die Casting Services?

From prototype to production

Our team of engineering and manufacturing experts have experience creating products for a wide variety of industries.

Our team of engineering and manufacturing experts have experience creating products for a wide variety of industries.

Quality Control

Quality is always the highest priority. We strive to meet and exceed all customer requirements and expectations and provide on-time delivery of defect-free precision parts.

Design expertise

For all aspects of design, from prototypes to production. Our expert pattern makers are especially skilled in creating castings with complicated cores

Production efficiency

To produce precision parts and reduce operating costs. We also offer a variety of finishing services, providing complete parts production from start to finish

Delivery options

- Just-in-time delivery that minimizes your need to store inventory

- A Fast-Cast program to respond to your parts emergencies

- Stocking services to help you manage the cast components inventory for regularly-used parts

- A Fast-Cast program to respond to your parts emergencies

- Stocking services to help you manage the cast components inventory for regularly-used parts

High standard testing

We partner with certified outside test labs to perform the full gamut of testing such as Physical Property Testing, Destructive & Non-Destructive Testing, X-Ray and Metallurgical Analysis, Corrosion Resistance (salt spray) testing of coatings, and virtually any test required by our customers.

Huarong Da Technology

IN THE EYES OF CUSTOMERS

High quality products and considerate service

We have received positive feedback from many customers.

Certificate

FAQ

Q: Are you a factory or trading company?

A: HuaRong Da is a professional manufacturer factory in DongGuang of China

Q: How can I get the quotation quickly?

A: We will submit the quotation in 24 hours if getting detailed information during working days. In order to quote for you earlier, please provide us the following information together with your inquiry.

1) 3D Step of Files and 2D Drawings.

2) Material requirement.

3) Surface treatment.

4) Quantity (per order/per month/annual). 5) Any special demands or requirements, such as packing, labels,delivery,etc.

Q: What are the main oversea markets of Metal?

A: Currently Metal regular oversea customers are from the US, the UK, Italy, Germany, France and India etc.

Q: How you do the quality control?

A: 1).Materials inspection by IQC;

2). The first sample inspected by QC, QC will do over check as per the parameters list and critical dimensions requested by customers, to decide if it can go ahead for production;

3). During processing, our IPQC will check the injection molded parts every 2 hours, ensure no any rejects;

4). FQC will check the products before sending to the warehouse;

5).100% inspected by OQC before shipping out. Q: What should we do if we receive defective products?

A: If receive defective product,please send us the photos, we will feedback to our engineers and QC departments and solve the problems ASAP.

Q: How to pack the moulds and products?

A: 1).For moulds, we will be coated one-layer anti-rust oil first,and then also will be covered thin films on the mould, finally pack into fumigation wooden case.

2).And as to products, we will pack into standard export cartons or as per customer’s request to pack.

Hot Searches