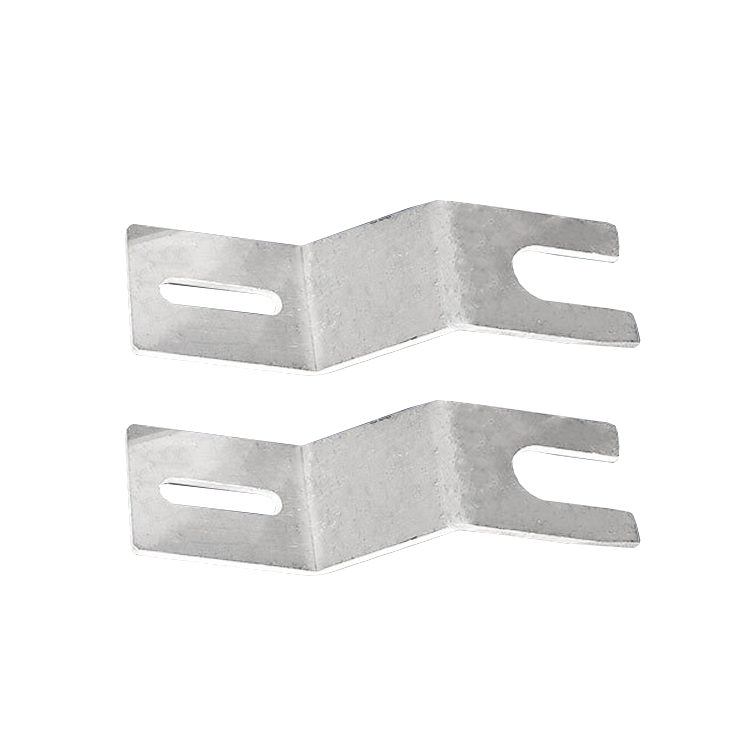

- Product Details

- {{item.text}}

Quick Details

-

Material:

-

Stainless Steel,Brass,Aluminum,Carbon steel or OEM

-

manufacture craft:

-

stamping

-

Product name:

-

custom stamping Parts

-

Surface treatment:

-

zinc plated,Ni-plated,Passivated,Tin-plated,

-

Application:

-

construction,furniture,industrial

-

Service:

-

OEM & ODM service

-

Equipment:

-

stamping parts services

-

Keyword:

-

oem metal stamping parts

-

Advantages of Metal Stamping:

-

Stamping is suitable for mass, complex part production

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

CHE

-

Model Number:

-

Stamping Parts

-

Material:

-

Stainless Steel,Brass,Aluminum,Carbon steel or OEM

-

manufacture craft:

-

stamping

-

Product name:

-

custom stamping Parts

-

Surface treatment:

-

zinc plated,Ni-plated,Passivated,Tin-plated,

-

Application:

-

construction,furniture,industrial

-

Service:

-

OEM & ODM service

-

Equipment:

-

stamping parts services

-

Keyword:

-

oem metal stamping parts

-

Advantages of Metal Stamping:

-

Stamping is suitable for mass, complex part production

Product details

|

Product Name

|

Stamping parts services

|

|

Material

|

Aluminum, copper, brass, stainless steel, steel, iron, alloy, zinc etc.

|

|

Size

|

Customized Size Or Client's Drawings

|

|

Tolerance

|

+/-0.01mm, 100% QC quality inspection before delivery, can provide quality inspection form

|

|

Finish

|

Anodizing,Brushing,Galvanized,laser engraving, Silk printing,polishing,Powder coating,etc

|

|

Color

|

Custom Accepted

|

|

Drawing format

|

3D/CAD/DWG//STEP/PDF

|

|

Quality Certification

|

IATF 16949 ISO14001, ISO9001,ROHS,etc

|

|

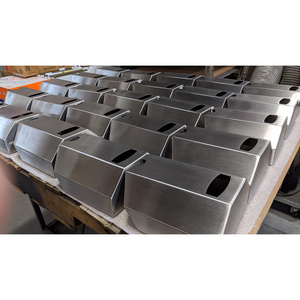

Types of Stamping

|

We offer single and multistage, progressive die, deep draw, fourslide, and other stamping methods to ensure the most effective

method for manufacturing your products |

|

Process

|

Laser;Cutting;Bending;Stamping

|

|

Service

|

Customize ODM OEM

|

|

Application

|

Industrial/auto/Motorcycle/electronics/electric power/Toys/Sports goods/Machinery equipment etc.

|

Advantages of Metal Stamping

Stamping is suitable for mass, complex part production. More specifically, it offers:

Complex forms, such as contours

High volumes (from thousands to millions of parts per year)

Processes such as fineblanking allow for forming of thick metal sheets.

Low cost-per-piece prices

Disadvantages of Metal Stamping

Metal stamping’s disadvantages are its setup costs and timelines. Production is quick and inexpensive after tool finalization. Its disadvantages include:

Longer lead times on first parts (as time is needed to create dies).

Tooling, check fixtures, and non-renewable engineering drive upfront costs needed for stamp production lines.

In order to ensure the product can be reliably produced to specification, suppliers often need to iterate on die design multiple times before production commences.

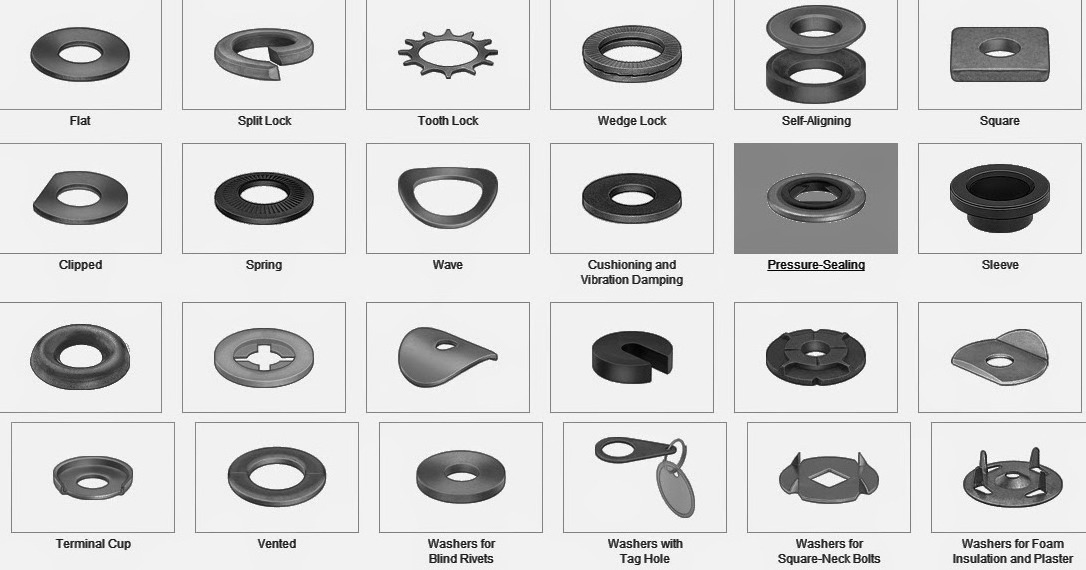

Related products

|

1, Main Materials

|

|

|

|

|

||||

|

Stainless Steel

|

SS201,SS301,SS303, SS304, SS316, SS416 etc.

|

|

|

|

||||

|

Steel

|

mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45# etc.

|

|

|

|

||||

|

Brass

|

HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc.

|

|

|

|

||||

|

Aluminum

|

AL6061, Al6063, AL6082, AL7075, AL5052, A380 etc.

|

|

|

|

||||

|

Iron

|

A36, 45#, 1213, 12L14, 1215 etc.

|

|

|

|

||||

|

Copper

|

C11000,C12000,C12000, C36000 etc.

|

|

|

|

||||

|

Plastic

|

ABS, PC, PE, POM, Nylon, PP, Peek etc.

|

|

|

|

||||

|

2, Surface Treatment

|

|

|

|

|

||||

|

Stainless Steel

|

Polishing, Passivating, Sandblasting, Laser engraving

|

|

|

|

||||

|

Steel

|

Zinc plating, Oxide black, Nickel plating, Chrome platingk, Carburized, Powder Coated

|

|

|

|

||||

|

Aluminum

|

Clear Anodized, Color Anodized, Sandblast Anodized, Chemical Film,Brushing,Polishing

|

|

|

|

||||

|

Plastic

|

Plating gold (ABS), Painting, Brushing (Acylic), laser engraving

|

|

|

|

||||

|

3, Quality Control

|

|

|

|

|

||||

|

1.Checking the raw material after they reach our factory------- Incoming quality control ( IQC)

|

|

|

|

|

||||

|

2. Checking the details before the production line operated

|

|

|

|

|

||||

|

3. Have full inspection and routing inspection during mass production---In process quality control(IPQC)

|

|

|

|

|

||||

|

4. Checking the goods after they are finished---- Final quality control(FQC)

|

|

|

|

|

||||

|

5. Checking the goods after they are finished-----Outgoing quality control(OQC)

|

|

|

|

|

||||

Company Introduction

Exhibition&Visitors

|

1) Design assistance and full engineering support .

|

|

|

|

|

||||

|

2) Professional at OEM CNC parts .

|

|

|

|

|

||||

|

3) Complete production lines for custom turning, milling, CNC machining sheet metal fabrication, stamping, bending, argon welding and surface treatment.

|

|

|

|

|

||||

|

4) Advanced machine tools, CAD/CAM programming software.

|

|

|

|

|

||||

|

5) Prototype machining capabilities.

|

|

|

|

|

||||

|

6) Strict quality control standards with a highly qualified inspection department .

|

|

|

|

|

||||

|

7) Continually upgrading and advancing our equipment to remain competitive .

|

|

|

|

|

||||

Certifications

Packaging&Shipping

FAQ

Q1: Are you trading company or manufacturer ?

A1: We are factory.

Q2: Can I visit your factory?

A2: Yes! Warmly welcome to visit our factory. It would be Great if you can inform us in advance.

Q3:The quality of your products?

A3:The company has advanced production and testing equipment .Every products will be 100% inspected by our qc department before

shipment.

Q4:How about your price?

A4:High quality products with reasonable price. Please give me a inquire, I will quoted you a price for you refer at once.

Q5:Could you provide free samples?

A5:We can provide free samples for standard fastener, But the clients will pay the Express charges.

Q6: What’s your Delivery Time?

A:Standard parts: 7-15days,Non-standard parts: 15-25days.We will make the delivery as soon as possible with the guarantee quality.

Q7: How should I order and make payment?

A7:By T/T, for samples 100% with the order; for production, 30% paid for deposit by T/T before production arrangement, the balance

to be paid before shipment.

A1: We are factory.

Q2: Can I visit your factory?

A2: Yes! Warmly welcome to visit our factory. It would be Great if you can inform us in advance.

Q3:The quality of your products?

A3:The company has advanced production and testing equipment .Every products will be 100% inspected by our qc department before

shipment.

Q4:How about your price?

A4:High quality products with reasonable price. Please give me a inquire, I will quoted you a price for you refer at once.

Q5:Could you provide free samples?

A5:We can provide free samples for standard fastener, But the clients will pay the Express charges.

Q6: What’s your Delivery Time?

A:Standard parts: 7-15days,Non-standard parts: 15-25days.We will make the delivery as soon as possible with the guarantee quality.

Q7: How should I order and make payment?

A7:By T/T, for samples 100% with the order; for production, 30% paid for deposit by T/T before production arrangement, the balance

to be paid before shipment.

Hot Searches