- Product Details

- {{item.text}}

Quick Details

-

Power:

-

0

-

Weight:

-

100 KG

-

Dimension(L*W*H):

-

70*60*120CM

-

Processing Types:

-

BOTTLE

-

Product name:

-

Air Bottle Washing Machine

-

Material:

-

Stainless Steel

-

Capacity:

-

1600-2000pcs/h

-

Cleaning type:

-

Electrostatic ion

-

Application:

-

Recycled Bottle Washer

-

Function:

-

Cleaning Equipment

-

Bottle type:

-

Glass Bottle Washiner

-

After Warranty Service:

-

Spare parts

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Certification:

-

GMP

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Jinfeng

-

Voltage:

-

220V

-

Power:

-

0

-

Weight:

-

100 KG

-

Dimension(L*W*H):

-

70*60*120CM

-

Processing Types:

-

BOTTLE

-

Product name:

-

Air Bottle Washing Machine

-

Material:

-

Stainless Steel

-

Capacity:

-

1600-2000pcs/h

-

Cleaning type:

-

Electrostatic ion

-

Application:

-

Recycled Bottle Washer

-

Function:

-

Cleaning Equipment

-

Bottle type:

-

Glass Bottle Washiner

-

After Warranty Service:

-

Spare parts

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Certification:

-

GMP

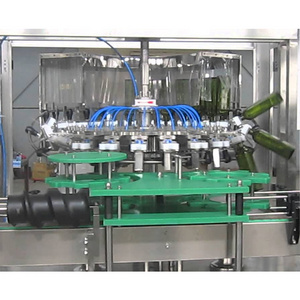

Rinser Perfume Plastic/Glass Cosmetic Bottles Air Cleaning Machine Bottle Washing Machine

Feature

1. Low energy consumption, clean pollution-free; easy operation, low failure rate; low prices.

2. The machine uses 304 stainless steel. Electrical parts adopt international brand OMRON and Schneider.

3. The use of double precision filter, electrostatic ion generator to ensure that no residual dust bottle.

4. Automatic storage dust particles to ensure clean air and room class operator health.

5. Applicable to pipeline operations, working with a variety of line matching and high efficiency. Than conventional washing, drying more efficient, saving and environmental protection.

6. The machine can be used in beverage plants, food plants, chemical plants, cosmetics factory, pharmaceutical production and other enterprises.

7.Caster design, convenient to move. Horizontal adjustment wheel suitable for different environment.

Working principle

Connecting the compressor, the switch to open the gas and gas pressure regulator to 4-6KG / CM². Adjust the height of the bottle holder according to the height of the bottle. You will need to clean the bottle upside down in the wash bottle holder, press down in the end. This time, the washing nozzle clean air rises and opens the solenoid valve to the bottle blowing clean air radio, direct the set time and then stop, and finally picked up the artificial clean bottle.

Scope of application

This machine is widely applicable to various types of glass bottles, plastic bottles cleaned before filling.

Technical parameters

1. Package: PE film cover inside and then plywood case.

2. Accept terms: EXW , FOB , C&F , CIF , etc.

3. Shipping by Express , Air or Sea based on customers' requirements and lowest cost solution.