Loading capacity: 5T

Inner diameter: 470-530mm

Steel coil width :914, 1000, 1220, 1250 mm.According to your actual drawing.

Working speed: 0-15m/min, adjustable

- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.25-0.7 mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

TOPPO

-

Voltage:

-

380V, 50HZ, 3 phase

-

Dimension(L*W*H):

-

about 7.7*1.5*1.3 m (L*W*H)

-

Weight:

-

3250 kg

-

Feeding width:

-

1000 mm

-

Marketing Type:

-

Easy to operate

-

Feature:

-

high production speed

-

Control System:

-

fully automatic

-

Operation Language:

-

Chinese/English/Spanish

-

Suitable Material:

-

Q235 or similar

-

Raw Material:

-

PPGI/Galvanized Sheet

-

Delivery Time:

-

35 working days after deposit

-

Color of Machine:

-

blue, gray, or your required color

-

Life Time:

-

at least 10 years

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

0-20 m/min

-

Rolling thinckness:

-

0.25-0.7 mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

TOPPO

-

Voltage:

-

380V, 50HZ, 3 phase

-

Dimension(L*W*H):

-

about 7.7*1.5*1.3 m (L*W*H)

-

Weight:

-

3250 kg

-

Feeding width:

-

1000 mm

-

Marketing Type:

-

Easy to operate

-

Feature:

-

high production speed

-

Control System:

-

fully automatic

-

Operation Language:

-

Chinese/English/Spanish

-

Suitable Material:

-

Q235 or similar

-

Raw Material:

-

PPGI/Galvanized Sheet

-

Delivery Time:

-

35 working days after deposit

-

Color of Machine:

-

blue, gray, or your required color

-

Life Time:

-

at least 10 years

1. Catalog

2. Details

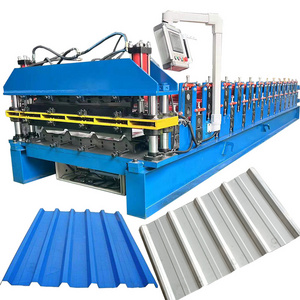

Metal Roofing Panel Corrugate Sheet Roll Forming Machine Manufacturer

The whole production process is

automatically controlled

by the computer. In this way, you can ensure accuracy and easy work.

Before production, you input your requirement into the control cabinet-for example, 3250 mm per piece, 20 pieces in total.

When the sheet comes to 3250 mm length, the machine will slow down-stop-cut-run again. When you get 20 pieces, the machine will entirely stop.

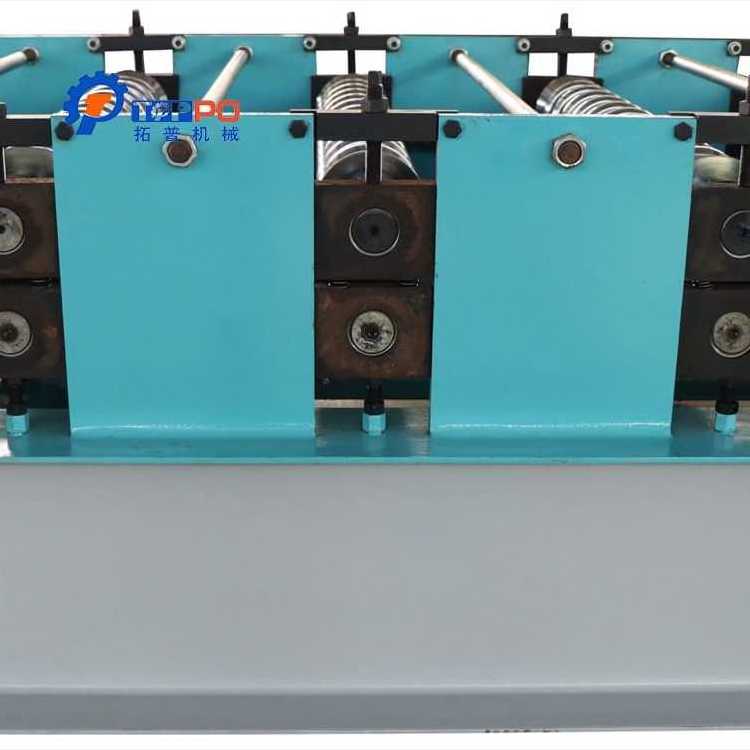

Uncoiler

Feeding table

It is used to control the width and position of the steel sheet.

The sheet is guided into the machine with correct position ,to make sure the panel is neat and parallel

The sheet is guided into the machine with correct position ,to make sure the panel is neat and parallel

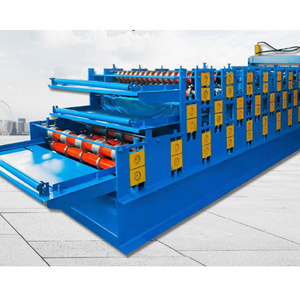

Main frame

Material :350 H steel

Feature:more table, no shaking

Feature:more table, no shaking

Forming rollers

Material:High grade 45# steel.

Roller stations :11-24 stations, according to your actual drawing.

Roller stations :11-24 stations, according to your actual drawing.

Control cabinet

Suitable power :

Feature:

380V, 50Hz, 3 phase. Or according to your need.

Feature:

The whole process is automatically controlled by the computer. In this way, you can ensure the accuracy and easy work.

3. Why Choose Us

fast driving system and fast cutting system

Our machine is equipped with fast driving system and fast cutting system. The production speed is much faster.

We invest more money into the machines, so you can get better components. In this way, we can insure stable performance and high quality.

|

High grade

|

Standard

|

Motorized cutting is 3 times faster

than traditional hydraulic cutting.

you will greatly improve your actual production speed. motorized cutting has the following advantages.

1. Easy maintenance. no extra hydraulic pipes to make it a mess

2. Low noise. the hydraulic station keeps working even it is not cutting.

3. Clean. No worry for oil leaking and making your factory dirty

you will greatly improve your actual production speed. motorized cutting has the following advantages.

1. Easy maintenance. no extra hydraulic pipes to make it a mess

2. Low noise. the hydraulic station keeps working even it is not cutting.

3. Clean. No worry for oil leaking and making your factory dirty

This fast drive improves speed to 25m/minute

from normal 10 m per minute (not include cutting).

Increase your production speed for quick delivery to your customers.

the other benefit for high speed is to reduce labor cost. Now you can reduce

50% working time, and save 50% worker salary.

Increase your production speed for quick delivery to your customers.

the other benefit for high speed is to reduce labor cost. Now you can reduce

50% working time, and save 50% worker salary.

Our feeding table is a curved design

. So the panel will be folded marks when feeding into the machine. There is handwheel to

adjust the steel bar, so you can adjust for different widths easily.

adjust the steel bar, so you can adjust for different widths easily.

4. Product Applications

The advantage of IBR sheet includes beautiful, classical appearance and grace taste.

It is widely used in village, hotel, exhibition, vacation village, family construction and outdoor decorating.

5. About Us

Hot Searches