Screw feeding machine can be used with various specifications of extruder, high-speed mixer, so that plastic powder, particles

from the storage box, by the screw automatic feeding (height can be determined according to the user), and control by the

processor feeding, with automatic feeding, fast feeding, labor saving, safe and reliable characteristics.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Huan

-

Year:

-

Customized

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

3.6*2.2*2.36m

-

Hollow part volume:

-

5L

-

Screw L/D Ratio:

-

24

-

Screw diameter (mm):

-

70 mm

-

Screw Heating Power(kW):

-

14.1 kW

-

Extruder Motor Power(kW):

-

18.5 kW

-

Mold Platen Size(Width)(mm):

-

430 mm

-

Mold Platen Size(Height)(mm):

-

470 mm

-

Air Pressure(MPa):

-

0.8 MPa

-

Air Comsumption(m³/min):

-

0.8 m³/min

-

Die Head Heating Power(kW):

-

6.5 kW

-

Accumulator Capacity(L):

-

0 L

-

Power (kW):

-

49.14

-

Weight (T):

-

5.5

-

Model Number:

-

HJS70D

-

Blow Moulding Type:

-

Extrusion Blow Moulding

-

Automatic:

-

Yes

-

Material:

-

PE,PP,PVC,PA...

-

Machine type:

-

Extrusion blow moulding machine

-

Range:

-

0-5L plastic bottle

-

Production:

-

hdpe extrusion blow molding machine

-

Rotary Cylinder Brand:

-

Customized

-

High Pressure Valve Brand:

-

Customized

-

Product name:

-

extrusion blow mould machine

Quick Details

-

Clamping Force (kN):

-

75

-

Output (kg/h):

-

70 kg/h

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Huan

-

Year:

-

Customized

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

3.6*2.2*2.36m

-

Hollow part volume:

-

5L

-

Screw L/D Ratio:

-

24

-

Screw diameter (mm):

-

70 mm

-

Screw Heating Power(kW):

-

14.1 kW

-

Extruder Motor Power(kW):

-

18.5 kW

-

Mold Platen Size(Width)(mm):

-

430 mm

-

Mold Platen Size(Height)(mm):

-

470 mm

-

Air Pressure(MPa):

-

0.8 MPa

-

Air Comsumption(m³/min):

-

0.8 m³/min

-

Die Head Heating Power(kW):

-

6.5 kW

-

Accumulator Capacity(L):

-

0 L

-

Power (kW):

-

49.14

-

Weight (T):

-

5.5

-

Model Number:

-

HJS70D

-

Blow Moulding Type:

-

Extrusion Blow Moulding

-

Automatic:

-

Yes

-

Material:

-

PE,PP,PVC,PA...

-

Machine type:

-

Extrusion blow moulding machine

-

Range:

-

0-5L plastic bottle

-

Production:

-

hdpe extrusion blow molding machine

-

Rotary Cylinder Brand:

-

Customized

-

High Pressure Valve Brand:

-

Customized

-

Product name:

-

extrusion blow mould machine

How to produce soft tube?

Raw Material

High barrier EVOH

Raw Material

PE

Automatic ice lolly tube,ice pops soft fruit jelly, packaging blow molding machine price

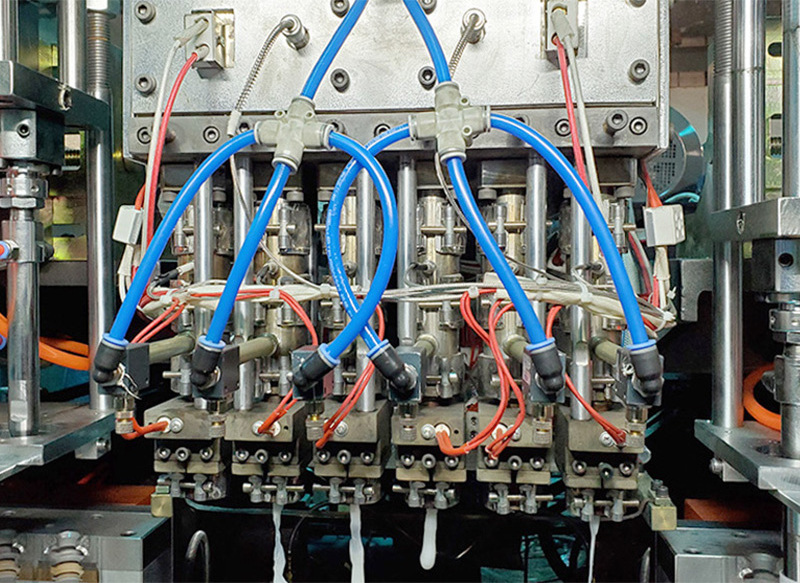

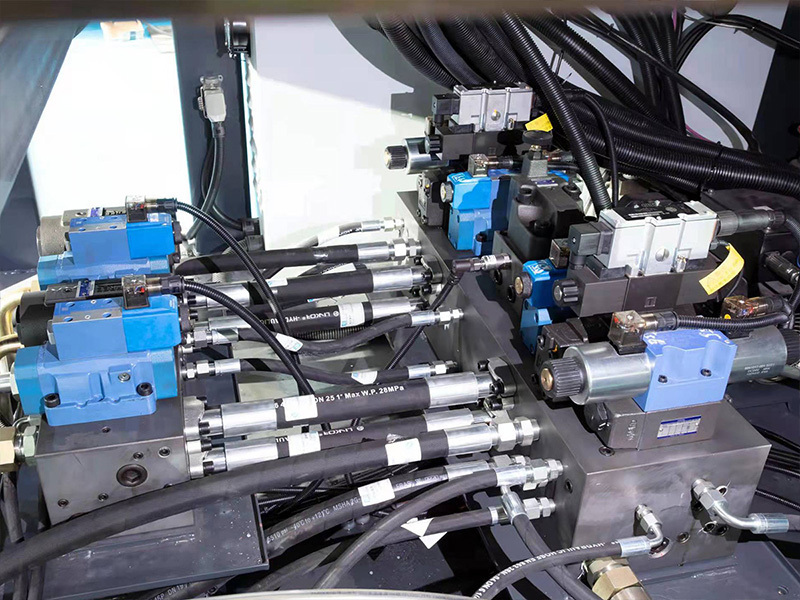

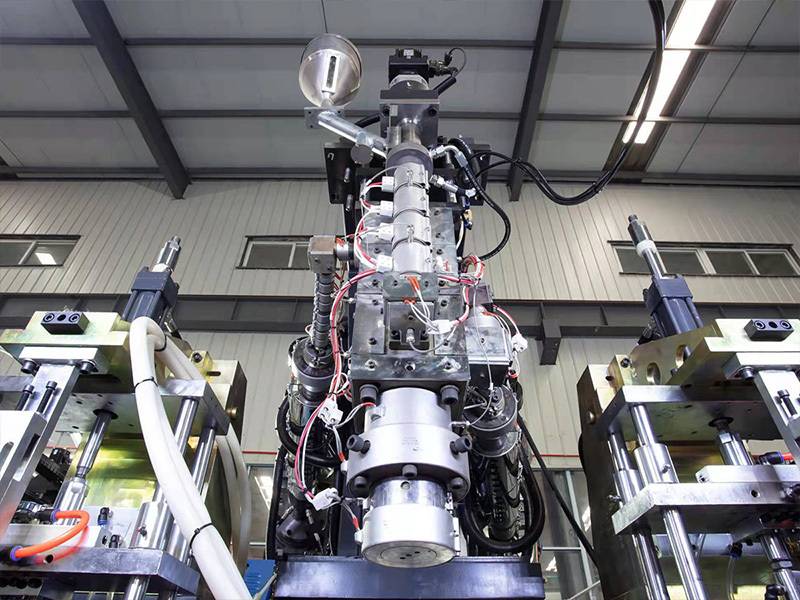

The extrusion blow molding machine is standard type machine with double station tie bar structure, The clamping structure is three

or four tie bars direct locking structure with automatic lubrication system.

The whole machine adopts computer control, simple operation, reliable work, high degree of automation, good interchangeability of

components,realize one machine multi-purpose. It can choose single and double mode-shifting models to meet different output

requirements. It can be equipped with single head, double head, four head, multi-layer head, double transparent line head and

servo wall thickness control head to meet the requirements of different products.

or four tie bars direct locking structure with automatic lubrication system.

The whole machine adopts computer control, simple operation, reliable work, high degree of automation, good interchangeability of

components,realize one machine multi-purpose. It can choose single and double mode-shifting models to meet different output

requirements. It can be equipped with single head, double head, four head, multi-layer head, double transparent line head and

servo wall thickness control head to meet the requirements of different products.

Product Details

Automatic ice lolly tube,ice pops soft fruit jelly, packaging blow molding machine price

Extrusion blow molding machine,which produce the EVHO cosmetic pearlized sun cream bottles automatically.High speed,high capacity,with 4 cavity.The machine is connect with IML,when producing the bottles, it can be labeling at the same time.

Specification

|

SPECIFICATIONS

|

HJS70D/F

|

|

Material

|

PE PP PVC PA...

|

|

Max container capacity

|

5L

|

|

Number of die

|

123,4,6

|

|

Machine Dimension(LxWxH)

|

3.6x2.2x2.36m

|

|

Total weight

|

5.5ton

|

|

CLAMPING UNIT

|

|

|

Clamping force

|

90kN

|

|

Platen openning stokes

|

180-480mm

|

|

Carriage stroke

|

450mm

|

|

Max mould size(WxH)

|

430x470mm/430x400mm

|

|

EXTRUSION UNIT

|

|

|

Screw diameter

|

70mm

|

|

Screw L/D ratio

|

24 L/D

|

|

(HDPE) Plasticizing capacity

|

70kg/h

|

|

Screw heating zone

|

3 zone

|

|

Screw heating power

|

14.1kw

|

|

Screw fan power

|

0.14kw

|

|

Extrusion motor power

|

18.5kw

|

|

DIE HEAD

|

|

|

Die head heating zone

|

3 zone

|

|

Power of die heating

|

6.5kw

|

|

ENERGY CONSUMPTION

|

|

|

Total power of machine

|

49.14kw

|

|

Power of oil pump motor

|

9.5kw

|

|

Air pressure

|

0.6-0.8 Mpa

|

|

Average energy consumption

|

28kw

|

|

Consumption compression air

|

1.2m3/min

|

|

Consumption cooling water

|

40L/min

|

More type bottles,just change the different shape mould,it can be customized as your requirement.

Related Product

Additional auxiliary machine can be equipped

Bottle leak test machine

The machine can be connected with the blowing line ,for checking the bottle is good or broken.It can test the hole of the bottle min. 0.2mm.

Bottle bagging packing machine

The machine is fully automatic,for packing the bottles in the pp bag.It's more convinent for carrying bottles

Packing & Delivery

1. cover the extrusion blow moulding machine by a film

2. installed on the wooden pallet with fumigation-free

3. delivered by standard container

Hot Searches