1) - * Tooling savings

2) - * Short setup time (saves on short production runs)

3) - * The capacity to process stiff,high durometer materials

4), - * Least amount of waste

|

Item

|

Food Grade Colorful Silicone Rubber Round O Ring Manufacturer

|

|

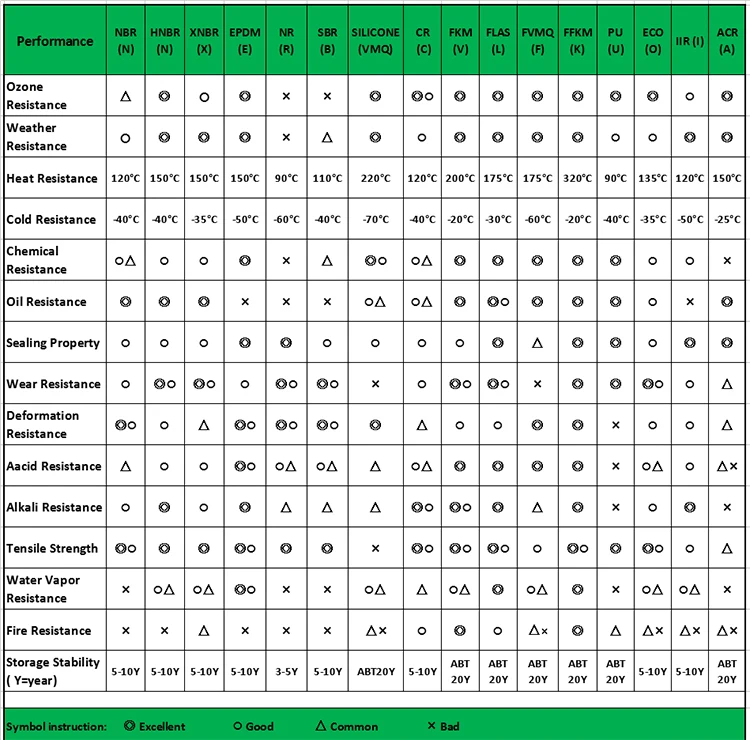

Material

|

EPDM, NBR, SBR, NR, Silicone(VMQ), Neoprene(CR), HNBR, XNBR, FKM, FFKM, FVMQ, FLAS, PTFE, PU, ECO, IIR, ACR, etc...

|

|

Certificate

|

IATF 16949:2016 / ISO 9001:2015 / ISO 45001:2018 / ISO 14001:2015 /REACH/ROHS/MSDS/LFGB/F D A

|

|

Drawing Format

|

.stp / .step / .igs /.stl /.dwg / .pdf

|

|

Color

|

Almost all PMS colors available for Silicone (VMQ); Mostly black for other rubber materials, if other colors are required, please

indicate it on inquiry. |

|

Parameters

|

Inch, centimeter, millimeter, etc.

|

|

Function

|

Industrial parts /daily supply / Automotive/ Medical device, etc...

|

|

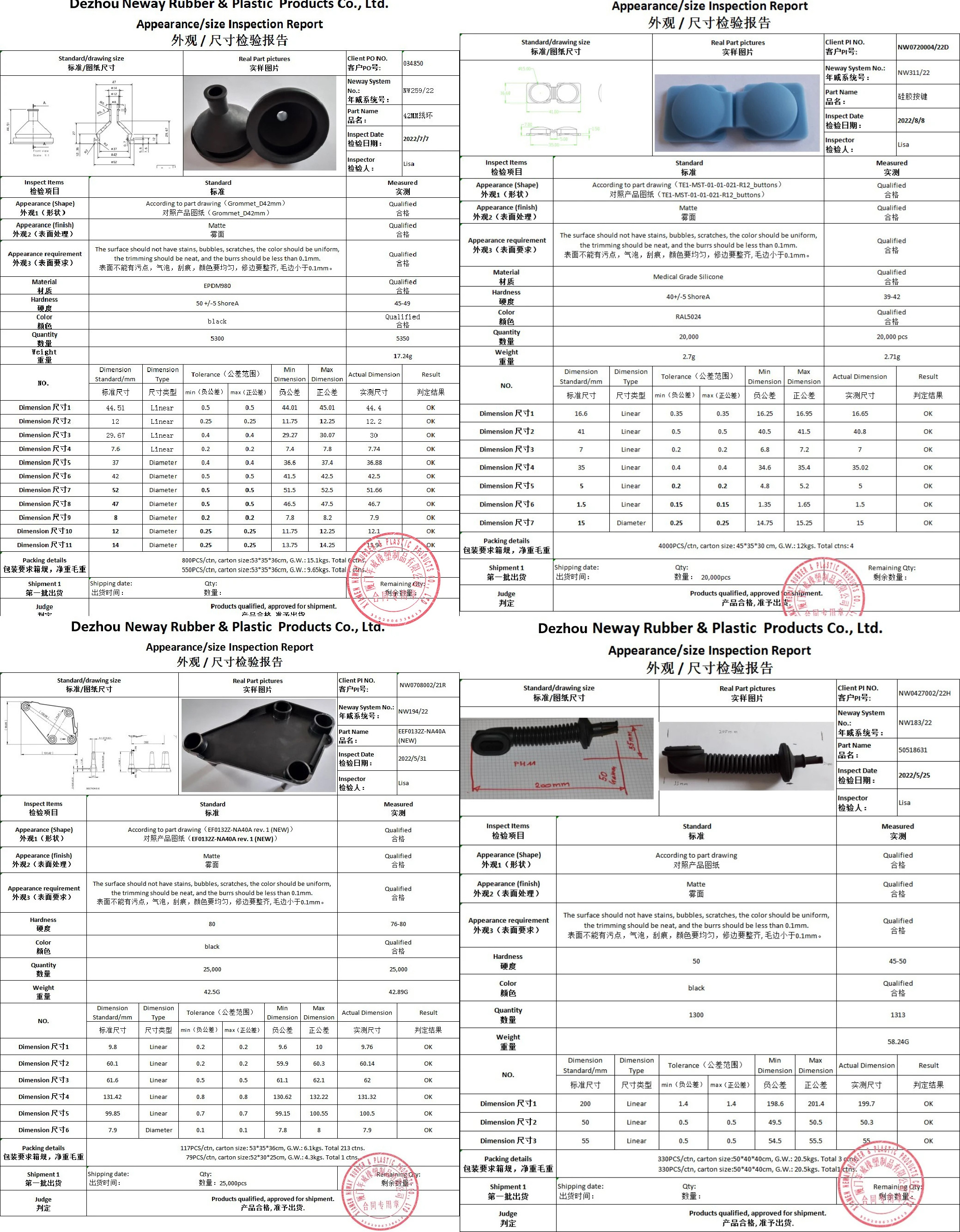

Surface Treatment

|

Matte, Common polishing, Mirror polishing, Texture, Laser Engraving, Power Coating (Painting), Printing, Segmented colors, Mixed

colors, etc. |

|

Mold Material

|

No. 50 steel, No. 45 steel, P20, 8407, H13, 718H, etc.

|

|

Mold Precision

|

If no special request, apply to ISO3302:2014 standards, class 2.

|

|

Mold Life-cycle

|

100,000-500,000 shots.

|

|

Packing

|

Pack in bulk / poly bag / bubble bag / color box.

|

|

Sample

|

Available. One cavity sample mold or 3D printing.

|

|

Price Tip

|

The price shown above is just for reference, final actual price depends on your design, material request, surface treatment, order

qty, package request, etc. |