- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

custom

-

Brand Name:

-

XMSD

-

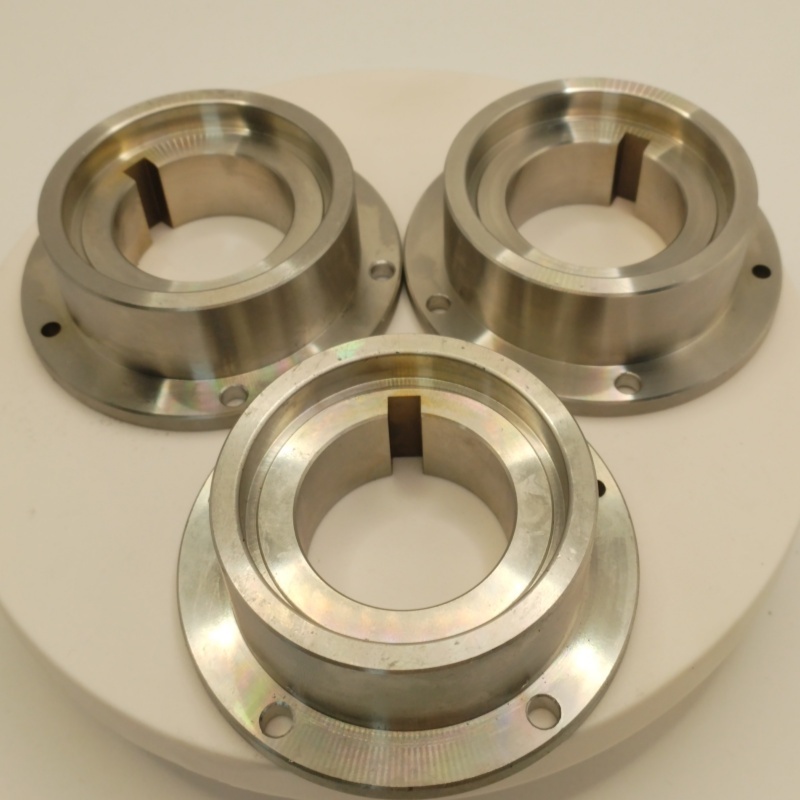

Product Name:

-

Shaft sleeve

-

Material:

-

Stainless steel

-

Processing technology:

-

Turning and wire cutting

-

Colour:

-

Natural color

-

Customized logo:

-

CNC engraving and laser engraving

-

Application scenarios:

-

Automobile, aviation, industry, intelligent equipment, communication

-

Sample:

-

Support

Quick Details

-

CNC Machining or Not:

-

Cnc Machining

-

Material Capabilities:

-

Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys, plastic

-

Place of Origin:

-

Sichuan, China

-

Model Number:

-

custom

-

Brand Name:

-

XMSD

-

Product Name:

-

Shaft sleeve

-

Material:

-

Stainless steel

-

Processing technology:

-

Turning and wire cutting

-

Colour:

-

Natural color

-

Customized logo:

-

CNC engraving and laser engraving

-

Application scenarios:

-

Automobile, aviation, industry, intelligent equipment, communication

-

Sample:

-

Support

Products Description

|

Item

|

Value

|

|

Name

|

Shaft sleeve

|

|

Brand

|

XMSD

|

|

Size

|

custom

|

|

Raw material

|

Stainless steel

|

|

Processing technology

|

Turning and wire cutting

|

|

Surface treatment

|

custom

|

|

Colour

|

Natural color

|

|

LOGO

|

custom

|

|

Application scenarios

|

automation equipment

|

|

Sample

|

Support

|

About Us

Chengdu Xinmaoshengda Technology Co., Ltd.

Certifications

TUV Rheinland

1. Strong factories&high-quality suppliers

2. Diversified machining equipment

3- Adequate production capacity

4- Experienced designers and engineers

5- Complete supply chain

6. High quality after-sales service

Why Choose Us

Are you still struggling with these things??

1. The product is complex and the supplier does not know how to design it

2. I want to take samples for trial sales, but the supplier has a high MOQ

3. Stable supply capacity is required, but suppliers have unpredictable delivery times

4. Unable to provide testing, quality cannot be guaranteed

What can we do to solve your problem?

Work shop

Design

1. Customers provide drawings and produce as needed

2. Assist in design and customize personalized needs

3. Independently design and assist customers in solving problems

Production

1. Design complex products

2. Products with strict tolerance requirements

3. High precision products

4. Beautiful and high-quality finished products

Quality inspection-100%

1. Before production - Material quality confirmation

2. In production - Confirmation of details such as production process and product tolerances

3. After production - Quality inspector conducts 100% inspection

4. Before packaging - conduct the final review

Details Images

1. Strict tolerance control

2- No scratches or burrs after sorting

3- Fluent and smooth chamfered edges

4-100% QC inspection

|

Item

|

value

|

|

Raw material

|

1. Metal:

Aluminum:

2024, 5052, 6061, 6063, 6082, 7075, etc.

Steel:

Carbon steel (10,15,20,25,30,35,40,45,80), etc.

Alloy steel:

(YG4 YG8 15Cr, 20Cr, 42CrMo), etc.

Stainless steel:

201, 202, 301, 302, 303, 304, 316, 420, 430, 440, 630, etc.

Brass, copper,bronze:

H62, H65. H90, HA177-2, HPb59-1, HSn70-1, etc.

Titanium:

TA1, TA2, TA3, TA4, TA5, TC1, TC2, TC3, TC4, TC5, etc.

2. Non metallic:

Plastics:

PU, ABS, POM, PE, PP, PVC, UPVC, PC, PMMA, PPS, PTFE nylon, acrylic, bakelite, etc.

Other:

carbon fiber, glass fiber, wood, hard rubber, etc.

|

|

Manufacturing services

|

Design, CNC machining, milling, turning, grinding, sheet metal processing, 3D printing, verification testing, assembly, etc

|

|

Surface roughness

|

Ra below 0.4

|

|

Accuracy control

|

Up to+/-0.005mm

|

|

surface treatment

|

anodizing,blackening,electroplating(zinc,nickel,chrome), electrophoresis, painting, powder coating,passivate,carburize etc.

|

|

Marking method

|

Laser engraving, CNC engraving, screen printing, transfer printing, etc

|

|

Detection equipment

|

Coordinate measuring machines, micrometers, microscopes, automatic altimeters, hardness testers, projectors, etc

|

|

Engineering drawing format

|

pdf,prt,dxf,dwg.pdf,ipg.png,step,iges

|

Recommend Products

NO.1 Machined parts

Processing equipment:

3-5 axis CNC machining center, intelligent lathe/milling machine, wire cutting machine, tapping machine, etc

Processing technology:

CNC turning, CNC milling, turning milling composite, wire cutting

NO.2 Sheet metal processing

Processing equipment:

Laser cutting machines, stamping machines, riveting machines, welding machines

Processing technology:

Laser cutting, stamping, bending, riveting, welding, etc

NO.3 3D printing

Processing technology:

SLA ,

SLS ,

MJF,

SLM,

DLP, ect.

NO.4 Injection molding

Processing technology:

Injection molding, encapsulation injection molding, insert injection molding, dual color injection molding

FAQ

1.Are you a manufacturer or a trading company?

We are a factory located in Sichuan, China with 15 years of rich experience. The facilities are complete, including quality inspection equipment, ERP system, and 40 machines. If necessary, we can provide you with material qualification certificates, sample quality inspection reports, etc.

2.How to obtain a quotation?

(1) Detailed drawings (PDF/STEP/IGS/DWG...)

: including quality, delivery date, materials, quality, quantity, surface treatment, and other information.

(2) No drawings:

Please provide a draft of samples, pictures, or detailed dimensions, and we will design 3D drawings for you. After verification, we will provide a quotation.

3. How do we ensure quality?

(1) Material Inspection - Check the surface and approximate dimensions of the material.

(2) The first inspection of production - ensuring critical dimensions in large-scale production.

(3) Sampling inspection - Check the quality before delivery to the warehouse.

(4) Pre shipment inspection -100% inspection by QC assistant before shipment.

4.What can you buy from us?

Metal and non-metallic products, sheet metal parts, switch hook type external lock lubrication device, tooling fixtures, molds

5.Can you provide samples before mass production?

Of course, sample fees are necessary. If possible, it will be returned during mass production.

6. After sales service team

If you have any questions after receiving the product, you can provide feedback within one month through voice calls, video conferences, emails, and other means. Our team will provide you with a solution within a week.

Hot Searches