- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

GANDONG

-

Dimension(L*W*H):

-

Depends on model

-

Weight:

-

8000 KG

-

Product name:

-

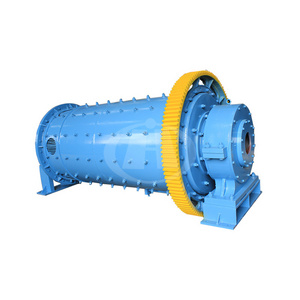

Grinding ball mill ore powder stone gold mining equipment

-

Output size:

-

0.074-0.4mm

-

Feeding size:

-

<25mm

-

Rotational speed(r/min):

-

30.7 r/min

-

Material:

-

Casting Steel

-

Installation:

-

Engineer's Guide

-

whole plant machine:

-

supply

-

flowchart design:

-

professional enginner service for you

-

Application:

-

Stone powder grinding

-

OEM/ODM:

-

Yes

Quick Details

-

Marketing Type:

-

New Product 2021

-

Capacity(t/h):

-

0.3-90 t/h

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

GANDONG

-

Dimension(L*W*H):

-

Depends on model

-

Weight:

-

8000 KG

-

Product name:

-

Grinding ball mill ore powder stone gold mining equipment

-

Output size:

-

0.074-0.4mm

-

Feeding size:

-

<25mm

-

Rotational speed(r/min):

-

30.7 r/min

-

Material:

-

Casting Steel

-

Installation:

-

Engineer's Guide

-

whole plant machine:

-

supply

-

flowchart design:

-

professional enginner service for you

-

Application:

-

Stone powder grinding

-

OEM/ODM:

-

Yes

Stone grinding machine ball mill from China

The ball mill is a key equipment to grind the crushed materials, and the ball mill is widely used in powder-making production line including cement, silicate, new-type building material, refractory material, fertilizer, ore dressing of ferrous metal and non-ferrous metal, glass ceramics, etc, and the ball mill can grind various ores and other materials with dry type and wet type. But according to discharge in different ways, the ball mill can be divided into gate ball mill and overflow ball mill. The gate ball mill is enforced discharging, relatively the discharge would be coarser, but the capacity would be higher, usually the gate ball mill used for primary grinding, the overflow ball mill used for secondary grinding.

Technical Specifications

|

SPECIFICATIONS FOR BALL MILL |

||||||

|

Model |

Rotation speed(r/min) |

Max ball load(t) |

Capacity t/h) |

Power(Kw) |

Dimension |

Weight (Kg) |

|

Φ900×1200 |

41.6 |

1.1 |

0.3~0.9 |

11 |

3843×1850×1400 |

4210 |

|

Φ900×2100 |

41.6 |

1.8 |

0.6~1.5 |

15 |

4743×1850×1400 |

6660 |

|

Φ1200×2400 |

35.1 |

4.0 |

1.6~4.1 |

37 |

5540×2300×1850 |

10020 |

|

Φ1200×2800 |

35.1 |

4.6 |

1.9~4.8 |

45 |

5940×2300×1850 |

10935 |

|

Φ1500×2400 |

30.7 |

7.0 |

2.8~6.5 |

55 |

6830×2930×2060 |

15430 |

|

Φ1500×3000 |

30.7 |

9.0 |

3.5~8.0 |

80 |

7430×2930×2060 |

16843 |

|

Φ1500×4000 |

30.7 |

11.11 |

4.8~10.5 |

110 |

9030×2930×2060 |

19103 |

|

Φ1500×4500 |

30.7 |

13.5 |

5.5~13.5 |

130 |

8930×2930×2060 |

20000 |

|

Φ1830×3600 |

25.04 |

15.0 |

4.0~21.5 |

155 |

9056×3654×2250 |

31600 |

|

Φ1830×4000 |

25.04 |

17.0 |

4.5~24 |

155 |

9456×3654×2250 |

32700 |

|

Φ1830×4500 |

25.04 |

19.0 |

5.2~26.0 |

180 |

9856×3654×2250 |

34210 |

|

Φ1830×5600 |

25.04 |

21.9 |

7~35 |

245 |

10956×3754×2250 |

39290 |

|

Φ2100×2200 |

23.8 |

15.0 |

3.0~22.0 |

150 |

7775×4060×3400 |

38793 |

|

Φ2100×3000 |

23.8 |

20.0 |

4.0~30.0 |

180 |

8475×4060×3400 |

41965 |

Re: This table only shows partial models, more model information please contact us .

Working principle

The ball mill is a horizontal rotating device transmitted by the outer gear. The materials are transferred to the grinding chamber through the quill shaft uniformly. There are ladder liner and ripple liner and different specifications of steel balls in the chamber. The centrifugal force caused by rotation of barrel brings the steel balls to a certain height and impact and grind the materials. The ground materials are discharged through the discharging board thus the grinding process is finished.

The machine is composed by feeding part, discharging part, turning part and driving part (reducer, small driving gear, electric motor and electric control). The quill shaft adopts cast steel part and the liner is detachable. The turning gearwheel adopts casting hobbing process and the drum is equipped with wear-resistant liner, which has good wear-resistance. The machine is with stable and reliable working condition. Moreover, according to different materials and discharging methods, there are dry ball mills and wet ball mills for choice.

Mineral processing line case show

Our goal is to provide customers with one stop service in the field of mining, including the minerals in the mineral analysis, mineral processing test, engineering design, equipment production, equipment installation, equipment debugging and of technical training etc integrated services, through the provision of our perfect services to solve all customer's problem from his investment to his return.

Jiangxi Well-tech International Mining Equipment Co.,Ltd. (Gandong Mining Equipment) is a large mineral processing service company specialized in designing, manufacturing, installing and debugging of mining equipment as well as providing flow sheet design and course training of mineral processing.

Our company covers an area of 48,000 square meters, the workshop covers 20,000 square meters, we have various large modernized machinery process facilities, professional engineering team and installation team.

Now our company is the largest manufacturer and exporter of gravity dressing equipment in China.

Pre-Sales Service

Inquiry and consulting support.

Sample testing support.View our Factory.

After-Sales Service

Training how to instal the machine, training how to use the machine.

Engineers available to service machinery overseas.