All the materials are inorganic and will not become food for termites and insects

- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Office Building

-

Design Style:

-

Modern

-

Type:

-

Building Material

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

yurui

-

Model Number:

-

zhuchen 01

-

Product name:

-

mgo board

-

Raw material:

-

MgO + MgSO4

-

Size:

-

1220*2440/1220*3000mm

-

Thickness:

-

3-20mm

-

Color:

-

Customized

-

classify:

-

standard board /sanding board

-

Density:

-

0.95-1.1kg/m3

-

Fireproof Grade:

-

Grade A1

-

Key Advantage:

-

Fire Resistant Morre

Quick Details

-

Warranty:

-

1 Year

-

After-sale Service:

-

Online technical support, Onsite Installation, Onsite Training, Onsite Inspection, Return and Replacement

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects, Cross Categories Consolidation

-

Application:

-

Office Building

-

Design Style:

-

Modern

-

Type:

-

Building Material

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

yurui

-

Model Number:

-

zhuchen 01

-

Product name:

-

mgo board

-

Raw material:

-

MgO + MgSO4

-

Size:

-

1220*2440/1220*3000mm

-

Thickness:

-

3-20mm

-

Color:

-

Customized

-

classify:

-

standard board /sanding board

-

Density:

-

0.95-1.1kg/m3

-

Fireproof Grade:

-

Grade A1

-

Key Advantage:

-

Fire Resistant Morre

Product Description

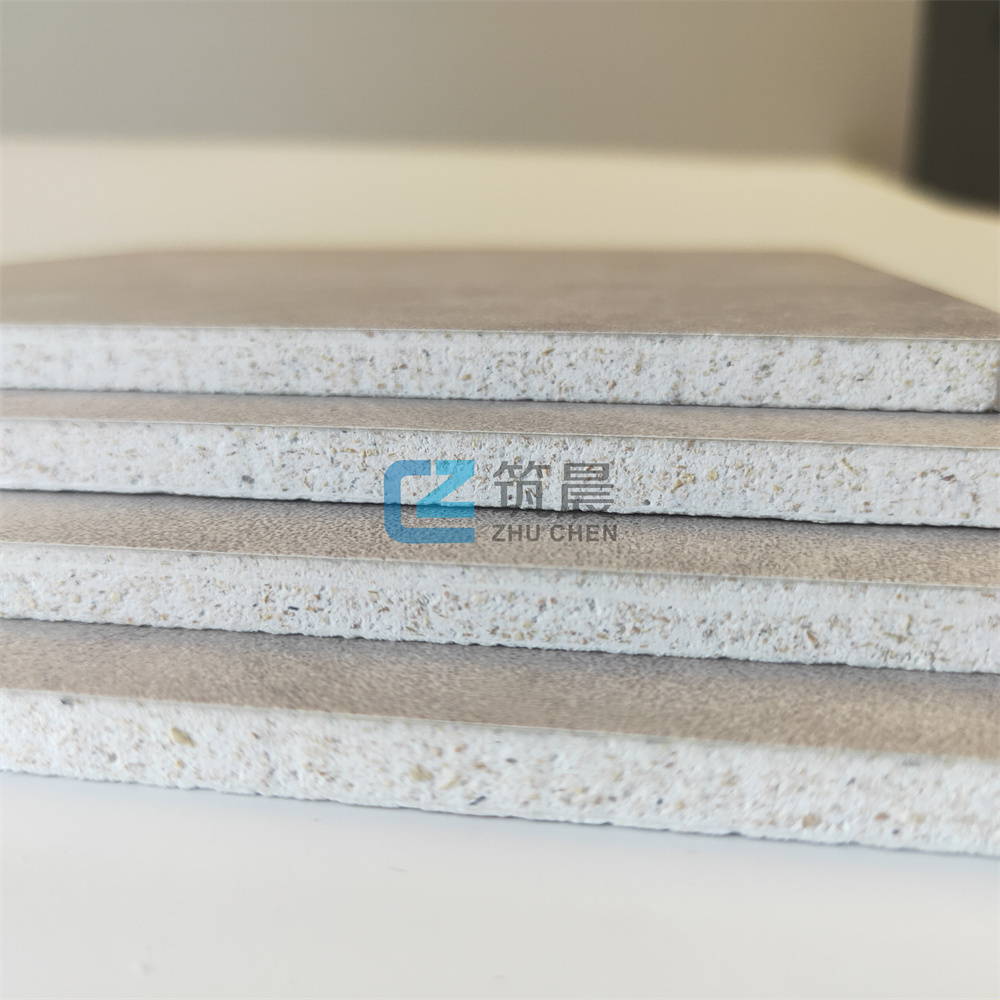

About MgO Board

The MgO Sulfate board is made from magnesium oxide, magnesium sulfate, Wood fiber, Perlite, fiberglass mesh. The highly purified MgO is used as the main fireproof material, wood fiber and perlite are used as filling materials.

|

Width

|

600/900/1200/1220, customize

|

|

|

|

|||

|

Length

|

2400-3050 mm, customize

|

|

|

|

|||

|

Thickness

|

3-50 mm

|

|

|

|

|||

|

Color

|

White; Pink; Purple; Green; Grey; Blue; Black; Brown, etc, we can customize for you

|

|

|

|

|||

|

Edge

|

Square; tapered ; T&G; L - shiplap

|

|

|

|

|||

|

Capacity

|

250-300 pieces/hour

|

|

|

|

|||

|

Type

|

Sanding mgo board; non-woven mgo board; HPL laminated mgo board ; Melamine paper laminated mgo board; mgo sip panels; mgo sandwich panel

|

|

|

|

|||

Why choose MGO

Why Builders Love MgO board?

* Moisture resistant – doesn’t warp or swell.

* Resistant to cold and heat – build in any season

* Easy to finish – prime and paint, tile, stucco, clad

* Impact-resistant

* Easy to use – lightweight and flexible

* Class A fire-rated and contains no asbestos

* Strong

* Easy to store

* Simple and inexpensive to dispose

* Resistant to cold and heat – build in any season

* Easy to finish – prime and paint, tile, stucco, clad

* Impact-resistant

* Easy to use – lightweight and flexible

* Class A fire-rated and contains no asbestos

* Strong

* Easy to store

* Simple and inexpensive to dispose

Why homeowners love MgO board?

* Insect-resistant

* Mold, mildew, and dry rot resistant

* Sound insulator – more than 40 decibels

* Eco-friendly

* Impact-resistant

* Non-toxic

* Mold, mildew, and dry rot resistant

* Sound insulator – more than 40 decibels

* Eco-friendly

* Impact-resistant

* Non-toxic

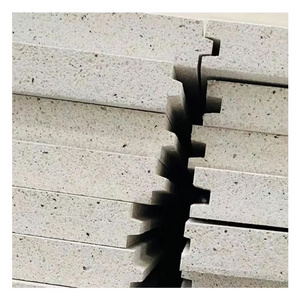

Different Types of Mgo Boards

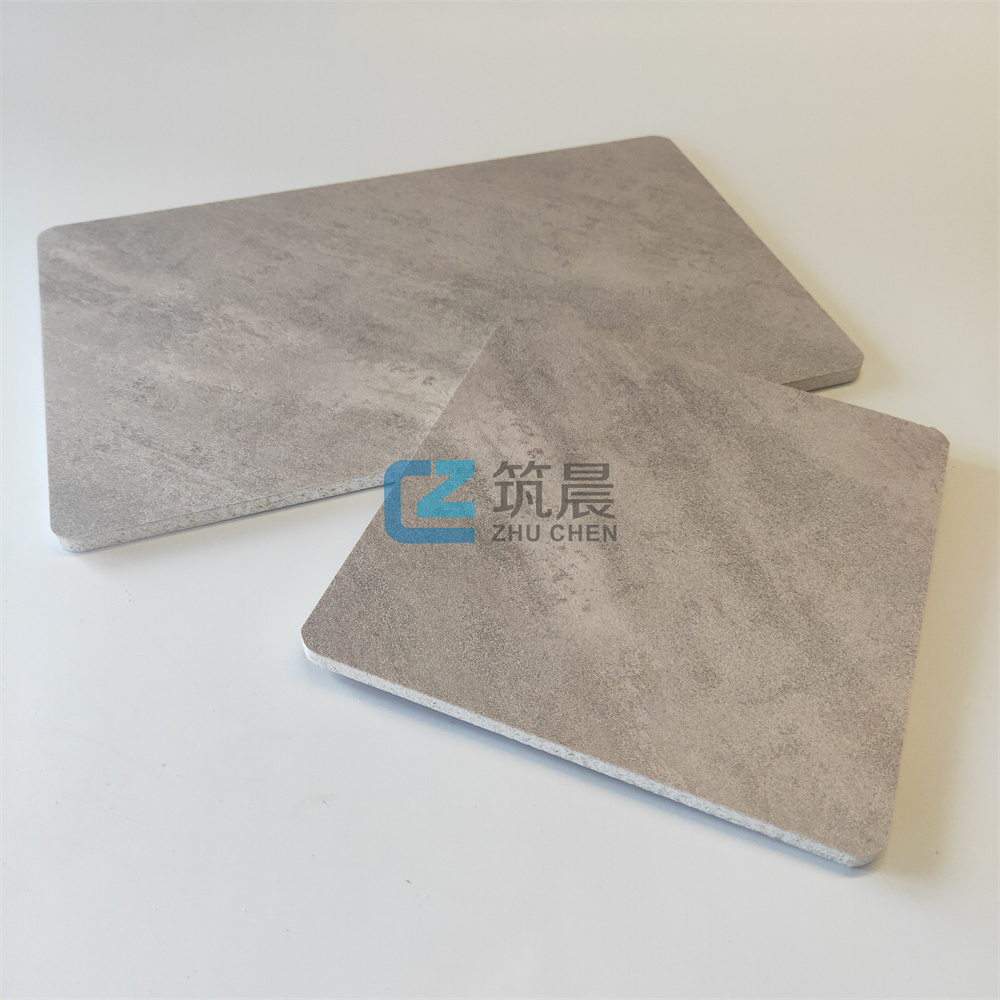

Standard MgO Board

It also called Non-woven MgO board, which has a smooth surface and rough backside.Its structure is Slurry layer + Non-woven +

fiber glass mesh + filling material later.

If you use it for wall , SIP, cladding, ...ect and not require strict precise tolerance of thickness, non-woven MgO board is

better choice as its price is cheaper than other types.

fiber glass mesh + filling material later.

If you use it for wall , SIP, cladding, ...ect and not require strict precise tolerance of thickness, non-woven MgO board is

better choice as its price is cheaper than other types.

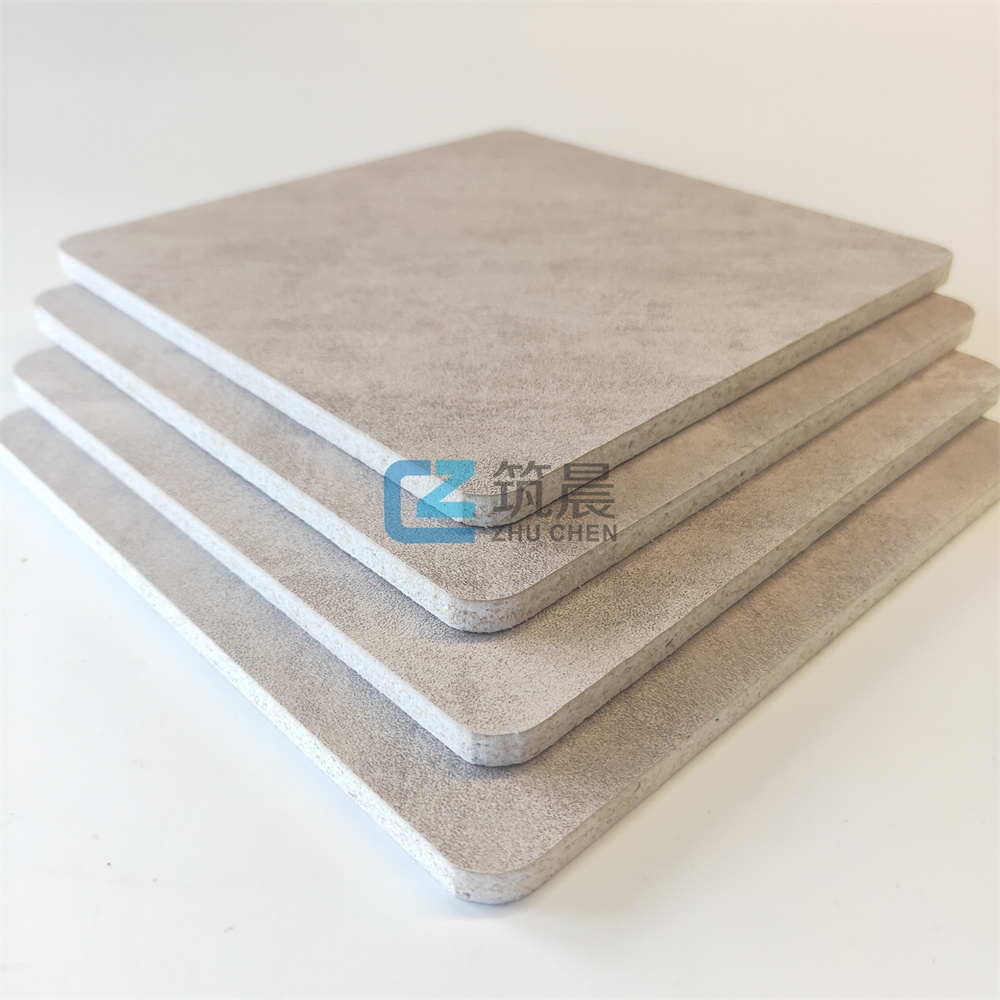

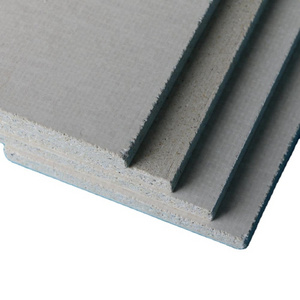

Sanded MgO Board

It have one more layer material - sanding material, and one more production process - sanding process.It's a premium quality MgO

board, it has a very smooth surface and sanded backside. Because the production process is difference from the common MgO board, the price is higher than the common MgO board.

board, it has a very smooth surface and sanded backside. Because the production process is difference from the common MgO board, the price is higher than the common MgO board.

Its backside has been sanded, so the thickness tolerance is very small. Many customers use this for deep process, such as

laminated with HPL, PVC, Aluminum, and Melamine paper.

laminated with HPL, PVC, Aluminum, and Melamine paper.

Strong MgO Fooring Board

This kind MgO board is specially designed for the projects need high strength performance. For examples, floorings. To this

board,we use over 6 layers high strength fiberglass mesh. Also, we chose a very nice glue coated fiberglass mesh. This mesh is

much longer working life and stronger than the common mesh.The bending strength of this board could reach 20MPa of 18mm.

board,we use over 6 layers high strength fiberglass mesh. Also, we chose a very nice glue coated fiberglass mesh. This mesh is

much longer working life and stronger than the common mesh.The bending strength of this board could reach 20MPa of 18mm.

Laminated MgO board

Now in our factory, we could provide the HPL laminated MgO board and melamine paper laminated MgO board.

This board combines the HPL/melamine paper on the Sanding MgO board. So, it has both the advantaged of the HPL/Melamine and the MgO board. Fireproof, high strength, waterproof and easy to clean.

This board combines the HPL/melamine paper on the Sanding MgO board. So, it has both the advantaged of the HPL/Melamine and the MgO board. Fireproof, high strength, waterproof and easy to clean.

MGO multi-application

About Us

Our Figures

Already

25

year experiences in producing MgO Board

We are 1st manufacturer of pure sulfate MgO board

Have 4 production line to focus on different requirements

Over 50 countries keep supplying and exporting to with reliable quality.

We are 1st manufacturer of pure sulfate MgO board

Have 4 production line to focus on different requirements

Over 50 countries keep supplying and exporting to with reliable quality.

Deeply study MgO board and production machinery for 20+years,own top technique.

1. Professional export team: full of experience to handle the export, transportation, files, and documents,

2. Experienced engineer and workers for production: Our general engineers own 18 years experience and professional technology in MGO board field, proficient in the process from No.1 generation MGO board production until the newest MGO board machine design/manufacturing.

3. Equipped with high automatic production line,ensure standard and consistent processing.

4. Strict production procedures and strict QC system and implement

2. Experienced engineer and workers for production: Our general engineers own 18 years experience and professional technology in MGO board field, proficient in the process from No.1 generation MGO board production until the newest MGO board machine design/manufacturing.

3. Equipped with high automatic production line,ensure standard and consistent processing.

4. Strict production procedures and strict QC system and implement

Strict Quality Control System

Work together with any third party inspection and factory audit. Whole system in factory from raw materials to finished product, to make sure the product are inspected and qualified.

Before each batch of raw materials into the factory, laboratory test firstly, and make the quality report, If it is qualified after the factory to use.

After the production of each batch of boards is completed, we will conduct sampling tests on this batch of boards, and carry out strict testing on the boards from various aspects such as density, strength, hardness etc.to ensure that the pass rate of each batch of boards reaches 99.8 %.

After the production of each batch of boards is completed, we will conduct sampling tests on this batch of boards, and carry out strict testing on the boards from various aspects such as density, strength, hardness etc.to ensure that the pass rate of each batch of boards reaches 99.8 %.

Customization

Rich experience in customization, custom products do not mean that customers give us a specification and we just follow them.

Generally, it is necessary to communicate with customers in depth about the application requirements of products, and at the same time, multiple proofing tests are required to finally form a qualified finished product.

Generally, it is necessary to communicate with customers in depth about the application requirements of products, and at the same time, multiple proofing tests are required to finally form a qualified finished product.

Packing & Shipping

Before Package

Before package, the board will be tested and inspected again by our lab and worker. Each of the board will be cleaned to make sure the board are clean and pick out any defect board.

During Package

We will use film to cover the pallets to avoid any mosiure during the transportation. Use green PET package strapping - Bundle the boards and reinforce the pallets.

FAQ

Q1. How do you pack your boards?

A: Generally, we pack our goods in strong wood pallets.

Q2. What are your terms of payment?

A: T/T 30% as deposit, and 70% against to the BL copy.

Q3. What are your terms of delivery?

A: FOB, CFR, CIF.

Q4. How about your delivery time?

A: Generally, it will take 15 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples. If you have special requirements of the products, we also could discuss with our engineers.

Q6. Could you provide samples?

A: Sure, please contact us now.

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Warmly welcome you contact me for your questions.

Hot Searches