- Product Details

- {{item.text}}

Quick Details

-

Design Printing:

-

Offer Printing

-

Material:

-

fiberglass

-

Feature:

-

Heat-Resistant

-

Use:

-

Carton Sealing

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

allesd

-

Model Number:

-

AT-0319K

-

Thickness:

-

0.145MM, 0.145mm

-

Product name:

-

Fiberglass Adhesive Tape

-

Application:

-

High temperature resistant packaging and bundling

-

Width:

-

25mm

-

Length:

-

50m

-

Size:

-

Custom Size Accepted

-

MOQ:

-

50rolls

-

Initial adhesion force:

-

>30

-

Paper tube diameter:

-

76mm

Quick Details

-

Adhesive:

-

Acrylic

-

Adhesive Side:

-

Single Sided

-

Adhesive Type:

-

Pressure Sensitive

-

Design Printing:

-

Offer Printing

-

Material:

-

fiberglass

-

Feature:

-

Heat-Resistant

-

Use:

-

Carton Sealing

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

allesd

-

Model Number:

-

AT-0319K

-

Thickness:

-

0.145MM, 0.145mm

-

Product name:

-

Fiberglass Adhesive Tape

-

Application:

-

High temperature resistant packaging and bundling

-

Width:

-

25mm

-

Length:

-

50m

-

Size:

-

Custom Size Accepted

-

MOQ:

-

50rolls

-

Initial adhesion force:

-

>30

-

Paper tube diameter:

-

76mm

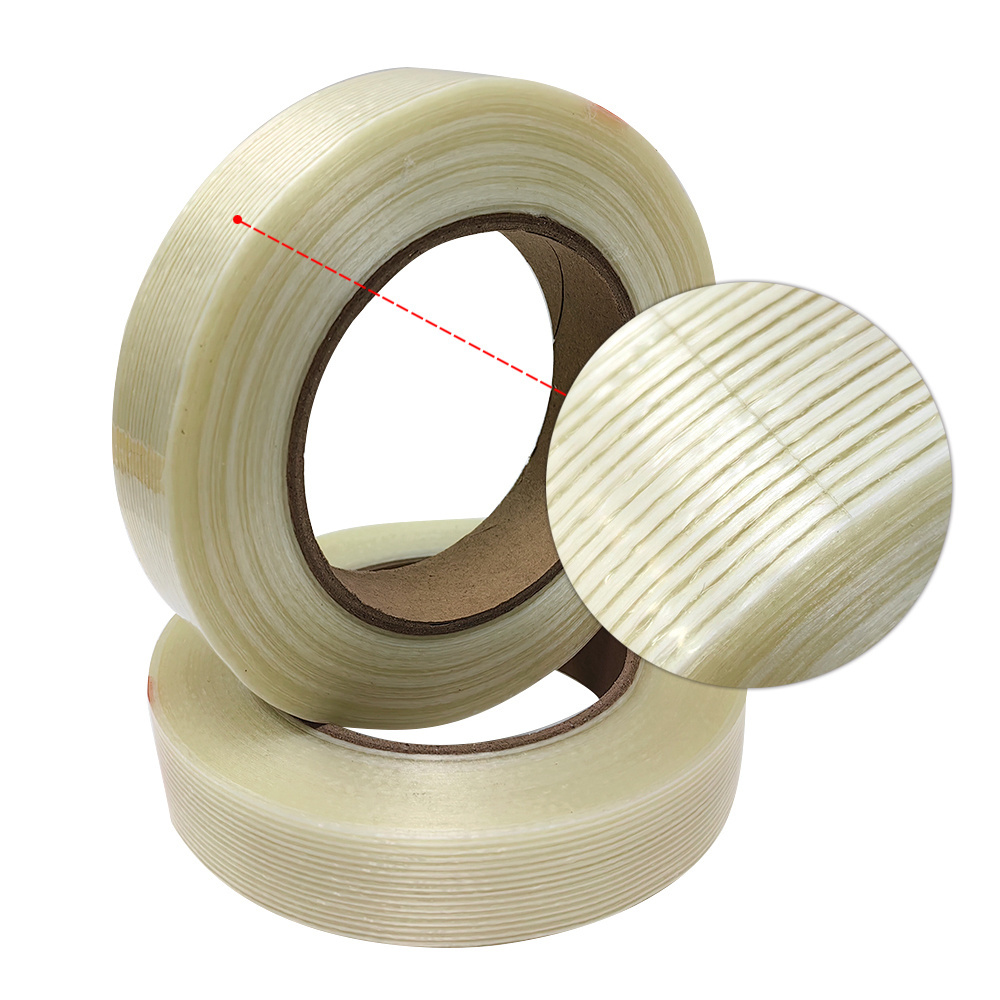

Products Description

|

Reinforced Filament Adhesive Tape

|

|

|

|

Material

|

PET + Filament Fiber

|

|

|

Adhesive

|

Pressure sensitive adhesive

|

|

|

Color

|

Transparent

|

|

|

Size

|

25mm*50m

|

|

|

Initial adhesion force

|

>30

|

|

|

180 ° peel force (N/25mm)

|

>35

|

|

|

Adhesive force

|

>72h

|

|

|

Tensile strength (N/in)

|

>500N

|

|

|

Elongation at break

|

5%

|

|

|

|

|

|

|

Product features:

|

1. Glass fiber tape uses transparent PET film or BOPP film as the backing material, and glass fiber yarn is reinforced to provide

high tensile strength and can prevent friction, scratches, and moisture. 2. The specially configured high-performance adhesive layer ensures appropriate initial adhesion and holding force, and can complete the bundling process in a timely manner by lightly pressing the tape on the surface being adhered, which is more convenient, fast, and economical than general operations. 3. High viscosity and strength can ensure that the minimum use of tape can meet the strict packaging requirements and reduce costs. 4. Transparent PET film can also be printed with text or advertisements for different needs. 5. The specially configured high-performance adhesive layer has a wide temperature adaptation range, and can be used for pasting operations in different environments such as winter (above 0 ℃) and summer (note that the optimal operating environment temperature is 15 ℃ -35 ℃, which becomes difficult to paste as the adhesive layer gradually hardens as the temperature decreases). Once pasted, it can maintain a good adhesion effect over a wider temperature range. |

|

|

Application:

|

Used for packaging household appliances, such as heavy goods such as refrigerators and washing machines, it can provide fixed

protection, and can also be used for packaging industrial products such as batteries. |

|

|

Tips on using tape

|

1. The adhesive strength depends on the contact area between the adhesive surface and the adhered surface, so appropriate pressure

and time can improve the adhesive strength Degrees. 2. The surface of the pasted material should be kept clean and free of oil stains. If necessary, solvents such as isopropanol and acetone can be used for cleaning. 3. The optimal operating environment temperature for pasting is room temperature, and at lower temperatures, it becomes difficult to stick due to the hard adhesive film. |

|

|

Suggested application

|

Packaging applications that require high viscosity, high strength, and high adhesion (high shear strength).

|

|

|

Storage

|

1. First in, first in. 2. Store in a dry and cool place and avoid direct sunlight.

3. Under suitable storage conditions,the storage period is two years from the date of production. |

|

Recommend Products

Hot Searches