- Product Details

- {{item.text}}

Quick Details

-

Power:

-

5kw

-

Weight:

-

250 KG

-

Dimension(L*W*H):

-

1650*980*1390mm

-

Year:

-

2021

-

Name:

-

puffed rice ball molding machine

-

Features:

-

Continuous & Automatic

-

Material:

-

Stainless steel

-

After-sales Service:

-

Full life

-

Manual:

-

English version

-

Layout:

-

AutoCAD format according to client's workshop

-

Guarantee:

-

1 year

-

Spare Parts:

-

1 set

-

Training:

-

Provide by technician in commissioning service

-

Recipe & Formula:

-

Provide free of charge

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DARIN

-

Voltage:

-

380V 50Hz

-

Power:

-

5kw

-

Weight:

-

250 KG

-

Dimension(L*W*H):

-

1650*980*1390mm

-

Year:

-

2021

-

Name:

-

puffed rice ball molding machine

-

Features:

-

Continuous & Automatic

-

Material:

-

Stainless steel

-

After-sales Service:

-

Full life

-

Manual:

-

English version

-

Layout:

-

AutoCAD format according to client's workshop

-

Guarantee:

-

1 year

-

Spare Parts:

-

1 set

-

Training:

-

Provide by technician in commissioning service

-

Recipe & Formula:

-

Provide free of charge

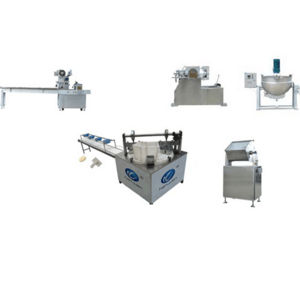

Promotional new products automatic puffed rice ball molding machine puff rice balls machine suppliers

Introduction

DRC-65 Cereal Bar Forming Machine

can be used for producing cereal bar with different shapes and sizes by changing the molds.

Ø Combined procedures into one: Filling materials - Forming shape - Cooling cereal bar - Demolding cereal bar - Conveying & cooling cereal bar.

Ø Controlled by Siemens PLC and touch screen with friendly interface. The staff could 180°rotate the touch screen, flexible and convenient. The controller languages can be Chinese, English, French, Arabic, Spanish, Russian, etc.

Ø Equipped with two sets of mechanical pressing molds, does not hurt materials and without material wastage.

Ø The forming molds are made by HMWHDPE and includes 36 pieces. The mold cavity can be designed with different shapes and sizes as customer’s requirements, such as cylinder, ball, square, round cake, heart, triangle.

Ø Equipped with sensors to accurately check the forming molds position, so the pressing mold could tightly fit, makes super cereal bar shaping.

Ø The conveying belt is made by HMWHDPE to avoid the materials sticking on the belt, also meet food grade.

Ø Using high performance frequency inverter, easy adjust speed, high efficiency, it can produce 24-hour continuously.

Ø After forming procedure and demolding procedure, there has fans to cool down the cereal bar to normal temperature.Easy operation, clean and maintenance.

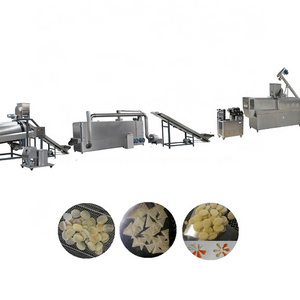

Paramenter of Cold Pet Treat Extrusion Line

|

Output

|

200-300kg/hr

|

|

Mixer Tank Size

|

390 x 380 x 410mm

|

|

Material Hopper Size

|

450 x 400 x 300mm

|

|

Mixer Tank Temperature

|

0-70℃

|

|

Mold Quan

|

39pcs, includes

|

|

|

Forming mold x 36pcs

|

|

|

Pressing mold x 2pcs

|

|

|

Demolding mold x 1pcs

|

|

Forming Mold size

|

509 x 173mm

|

|

Effective mold size

|

380 x 140mm

|

|

Min. distance between mold cavity

|

11mm

|

|

Power

|

10.8kw

|

|

Weight

|

1200kg

|

|

Dimension

|

5300 x 965 x 1850mm

|

Details Images

Hot Searches