Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

1year

-

Brand Name:

-

Hichwan

-

Model Number:

-

ES, ES

-

Place of Origin:

-

Shandong, China

-

Horsepower:

-

To be selected

-

Outlet Size:

-

According to customer requirements

-

Power:

-

To be negotiated(11-3550KW)

-

motor:

-

Electric motor

-

industrial water pump:

-

centrifugal pump

-

double suction pump:

-

Double Suction Split Casing Centrifugal Pump

-

Pump Type:

-

Horizontal Pump

-

Color:

-

The choice is yours

-

Oil or Not:

-

Oil Free

-

Production Capacity:

-

300set/Year

-

Motor:

-

100% Copper Wire

-

electric water pump:

-

industrial pump

Quick Details

-

Application:

-

Automotive Industry, Commercial Buildings, Developing World Water Solutions, Drinking water treatment, Food and Beverage Industry, Industrial Utilities, Irrigation and Agriculture, Metal and Equipment Manufacturers, Mining industry, Pharmaceutical industry, Raw Water Intake, Washing and Cleaning, Wastewater Transport and Flood Control, wastewater treatment, Water Distribution, Water Treatment Solutions

-

Pressure:

-

High Pressure

-

Voltage:

-

380V/415V/660V/1140V

-

Warranty:

-

1year

-

Brand Name:

-

Hichwan

-

Model Number:

-

ES, ES

-

Place of Origin:

-

Shandong, China

-

Horsepower:

-

To be selected

-

Outlet Size:

-

According to customer requirements

-

Power:

-

To be negotiated(11-3550KW)

-

motor:

-

Electric motor

-

industrial water pump:

-

centrifugal pump

-

double suction pump:

-

Double Suction Split Casing Centrifugal Pump

-

Pump Type:

-

Horizontal Pump

-

Color:

-

The choice is yours

-

Oil or Not:

-

Oil Free

-

Production Capacity:

-

300set/Year

-

Motor:

-

100% Copper Wire

-

electric water pump:

-

industrial pump

Product Description

-Eco-friendly

The traditional grease-lubricated bearings (including both rolling contactbearings and sliding contact bearings) are replaced with self-lubricating sliding contact bearings, eliminating the pollution hazard to both thetransmission medium and the site environment.

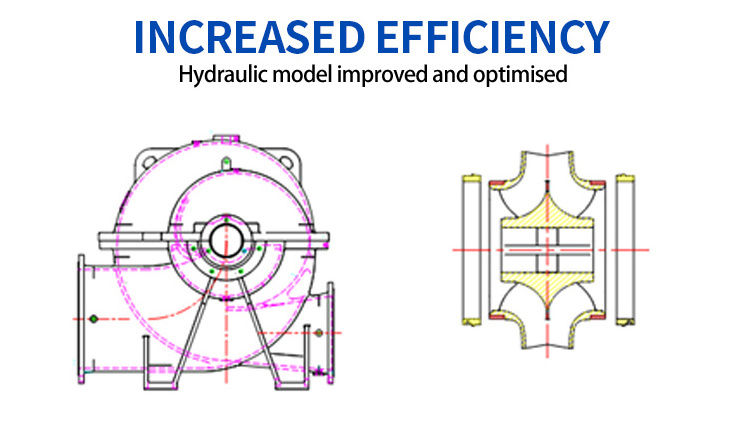

-Energy-saving

A. Lubricant is no longer needed.

B. Less material used.

C. Increased efficiency.

-

Maintenance-free and low operation cost

A. Maintenance-free bearing eliminates manual inspection.

B. The non-driving end seal adopts static seal technique,eliminating one mechanical seal.

-Longer bearing life

The service life of traditional ball bearings is affected by the operating conditions. The general design life is about 2-5 years. With this product,the bearing service life can reach 5-10 years.

-

Safer, smoother, and more reliable operation

A. Carefully designed to reduce vibration and noise.

B. The non-driving end adopts static sealing, which reduces onepoint of failure.

C. The bearing cage of the traditional double-suction pump isremoved, the length of the pump shaft is shortened, improving theoperational stability of the pump.

D. Diaphragm coupling for the full range of pumps.

|

Inlet diameter(mm)

|

|

φ150 ~ φ500

|

|

φ600 ~ φ1200

|

|

||

|

Frequency(Hz)

|

|

50

|

60

|

50

|

60

|

||

|

Flow(m3/min)

|

|

5~40

|

6~50

|

40~200

|

45~250

|

||

|

Head(m)

|

|

5~130

|

8~180

|

10~120

|

15~180

|

||

|

Pump stage

|

High speed

|

2,4

|

2,4

|

6,8,10,12

|

6,8,10,12

|

||

|

|

Low speed

|

4,6

|

4,6

|

8,10,12,14

|

8,10,12,14

|

||

Product Paramenters

Only some models are shown,please contact us for more parameters.

|

Model

|

|

Flow

|

Head

|

Speed

|

Motor Power

|

Efficiency

|

NPSHr

|

|

|

|

|

m³/h

|

m

|

R/min

|

KW

|

%

|

|

|

|

200ES-11

|

O

|

288

|

11

|

1460

|

15

|

84

|

2.3

|

|

|

|

A

|

270

|

9.5

|

|

11

|

83.5

|

2.8

|

|

|

|

B

|

258

|

8.5

|

|

11

|

83

|

2.9

|

|

|

|

C

|

246

|

7.4

|

|

7.5

|

82

|

3

|

|

|

200ES-16

|

O

|

264

|

16

|

1460

|

18.5

|

83

|

2

|

|

|

|

A

|

276

|

15

|

|

18.5

|

82

|

2.2

|

|

|

|

B

|

282

|

13.6

|

|

15

|

82

|

2.8

|

|

|

|

C

|

294

|

12.4

|

|

15

|

80.5

|

3

|

|

|

200ES-26

|

O

|

300

|

26

|

1460

|

30

|

83

|

2.2

|

|

|

|

A

|

270

|

24

|

|

30

|

82

|

2.2

|

|

|

|

B

|

258

|

21.6

|

|

22

|

81

|

2.3

|

|

|

|

C

|

240

|

19.2

|

|

22

|

79

|

2.3

|

|

|

200ES-40

|

O

|

306

|

40

|

1460

|

55

|

81

|

2.3

|

|

|

|

A

|

294

|

37

|

|

45

|

81

|

2.3

|

|

|

|

B

|

282

|

33

|

|

37

|

80

|

2.3

|

|

|

|

C

|

270

|

30

|

|

37

|

79

|

2.3

|

|

|

200ES-65

|

O

|

372

|

63

|

1460

|

90

|

79

|

2.6

|

|

|

|

A

|

348

|

56

|

|

75

|

77.5

|

2.6

|

|

|

|

B

|

330

|

50

|

|

75

|

76.5

|

2.7

|

|

|

|

C

|

312

|

44

|

|

55

|

75

|

2.7

|

|

|

250ES-13

|

O

|

414

|

13.5

|

1460

|

22

|

82

|

3

|

|

|

|

A

|

396

|

11.8

|

|

18.5

|

82

|

3.6

|

|

|

|

B

|

384

|

10.5

|

|

15

|

82

|

3.7

|

|

|

|

C

|

366

|

9.2

|

|

15

|

81

|

3.7

|

|

|

250ES-20

|

O

|

432

|

20.4

|

1460

|

37

|

84

|

2.7

|

|

|

|

A

|

408

|

18.5

|

|

30

|

82

|

2.9

|

|

|

|

B

|

396

|

17.2

|

|

30

|

81

|

3.5

|

|

|

|

C

|

378

|

15

|

|

22

|

79

|

3.8

|

|

|

250ES-30

|

O

|

456

|

31

|

1460

|

55

|

84

|

3

|

|

|

|

A

|

420

|

28.5

|

|

45

|

83

|

3

|

|

|

|

B

|

396

|

26

|

|

45

|

82

|

3

|

|

|

|

C

|

372

|

23.5

|

|

37

|

82

|

3

|

|

|

250ES-50

|

O

|

498

|

50

|

1460

|

90

|

83

|

3

|

|

|

|

A

|

450

|

44

|

|

75

|

83

|

3

|

|

|

|

B

|

420

|

41

|

|

75

|

82

|

3

|

|

|

|

C

|

402

|

37

|

|

55

|

82

|

3

|

|

|

250ES-76

|

O

|

510

|

76

|

1460

|

160

|

79

|

3

|

|

|

|

A

|

450

|

70

|

|

132

|

78

|

3

|

|

|

|

B

|

402

|

64

|

|

110

|

77

|

3

|

|

|

|

C

|

372

|

58

|

|

90

|

76

|

3

|

|

|

300ES-16

|

O

|

588

|

16.5

|

1460

|

37

|

84

|

3.8

|

|

|

|

A

|

552

|

15

|

|

30

|

83

|

4.5

|

|

|

|

B

|

528

|

13.6

|

|

30

|

82

|

4.7

|

|

|

|

C

|

516

|

11.6

|

|

22

|

81

|

4.8

|

|

|

300ES-25

|

O

|

576

|

25.5

|

1460

|

55

|

85

|

3.3

|

|

|

|

A

|

564

|

23

|

|

55

|

84

|

3.6

|

|

|

|

B

|

552

|

21

|

|

45

|

83

|

4.2

|

|

|

|

C

|

516

|

19

|

|

37

|

82

|

4.6

|

|

|

300ES-42

|

O

|

576

|

42

|

1460

|

90

|

85

|

3.4

|

|

|

|

A

|

552

|

38

|

|

75

|

85

|

3.4

|

|

|

|

B

|

528

|

35

|

|

75

|

84

|

3.5

|

|

|

|

C

|

504

|

31

|

|

75

|

83

|

3.8

|

|

|

300ES-65

|

O

|

600

|

65

|

1460

|

160

|

84

|

3.6

|

|

|

|

A

|

588

|

58

|

|

132

|

82

|

3.6

|

|

|

|

B

|

564

|

52

|

|

110

|

82

|

3.6

|

|

|

|

C

|

552

|

46

|

|

110

|

81

|

3.6

|

|

|

300ES-100

|

O

|

720

|

100

|

1460

|

280

|

80

|

4

|

|

|

|

A

|

630

|

91

|

|

220

|

80

|

4

|

|

|

|

B

|

588

|

82

|

|

200

|

79

|

4

|

|

|

|

C

|

552

|

74

|

|

160

|

79

|

4

|

|

Pump casing & Casing cover

The pressure chamber of ES type double suction pump has a trapezoidal cross-section. To avoid shape distortion due to casting errors, the flange of the casing cover is designed to be slightly larger than the flange of the casing.For a split casing pump with a lower head, a single-shell structure is used. To reduce the pressure pulsation during the operation, the diaphragm tongue of the pump pressure chamber is designed with an inclined shape.For a split casing pump with a higher head, the radial force generated when the pump is running is large. Hence a double volute chamber structure is adopted.

|

|

Standard specification

|

Special specification

|

|

Extraction medium

|

Clear water, industrial water, river water

|

Sea water, paper pulp liquid (water-like), organic liquid fertilizer, medium with impurities

|

|

Medium temperatures

|

Below 80℃

|

80℃~300℃

|

|

Shaft seal

|

Static seal/

Mechanical seal |

Static seal/

Mechanical seal |

|

Bearing and lubricant

|

Maintenance-free

water-based lubricant |

Special maintenance-free self-lubricating

|

|

Rotating direction

|

Clockwise

(From the prime mover) CW |

Anti-clockwise

CCW |

|

Import and export flange

|

GB

|

JIS. ANSI. API. JPI etc.

|

|

Inlet & outlet direction

|

Horizontal inlet,

horizontal outlet |

As per customer requirements

|

|

Drive method

|

Electric motors, internal combustion engines, steam turbines, etc.

|

Electric motors, internal combustion engines, steam turbines, etc.

|

Changes in structure and lubrication methods improve efficiency

The bearing of the ES type double suction pump is a self-lubricating bearing located inside the pump body to support the rotor components.lts biggest advantage is maintenance-free (that is, no daily maintenance is required). lt has the advantages of small installation space, stable operation, high efficiency, low operation and maintenance.

|

Component

|

Standard specification

|

Special specification

|

|

Pump casing & Casing cover

|

Grey iron/ Ductile iron

|

Stainless steel/

Corrosion-resistant stainless steel |

|

Impeller

|

Grey iron/

Cast steel/ Stainless steel |

Corrosion-resistant stainless steel/

Bronze |

|

Shaft

|

Carbon steel

|

Stainless steel/

Corrosion-resistant stainless steel |

|

Bearing

|

Maintenance-free water-based lubricant

|

Special maintenance-free self-lubricating

|

|

Seal ring

|

Carbon steel/

Copper |

Grey iron/

Stainless steel/ Corrosion-resistant stainless steel |

Hot Searches