- Product Details

- {{item.text}}

Quick Details

-

Mold Height(mm):

-

280 - 800 mm

-

Ejector Stroke(mm):

-

180 mm

-

Ejector Force(kN):

-

126 kN

-

Theoretical Shot Volume(cm³):

-

1689 cm³

-

Injection Rate (g/s):

-

1537 g/s

-

Injection Weight (g):

-

446 g

-

Screw Speed (rpm):

-

1 - 4200 rpm

-

Screw diameter (mm):

-

700 mm

-

Screw L/D Ratio:

-

20

-

Distance between Tie Bars:

-

720x720 mm

-

Weight (KG):

-

5000 kg

-

Place of Origin:

-

Jiangsu, China

-

Open Stroke(mm):

-

420 mm

-

Model Number:

-

BST-4000

-

Brand Name:

-

U Tech

-

Power (kW):

-

37 kW

-

Warranty of core components:

-

2

-

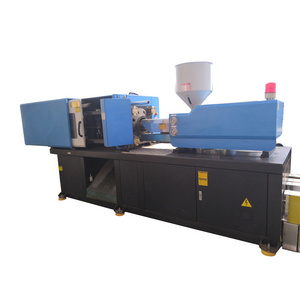

Product name:

-

Plastic Products Injection Molding Machine

-

Name:

-

Plastic Making Injection Molding Machine

-

Application:

-

Injection Molding Machine Molds Change

-

Color:

-

Customzied

-

Advantage:

-

High efficiency

-

Material:

-

Stainless Steel 304 / 316L

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Product:

-

PET preform Injection Molding Machine

Quick Details

-

Distance between Tie Bars(Width)(mm):

-

720mm

-

Distance between Tie Bars(Height)(mm):

-

720mm

-

Plasticizing Capacity(g/s):

-

446

-

Mold Height(mm):

-

280 - 800 mm

-

Ejector Stroke(mm):

-

180 mm

-

Ejector Force(kN):

-

126 kN

-

Theoretical Shot Volume(cm³):

-

1689 cm³

-

Injection Rate (g/s):

-

1537 g/s

-

Injection Weight (g):

-

446 g

-

Screw Speed (rpm):

-

1 - 4200 rpm

-

Screw diameter (mm):

-

700 mm

-

Screw L/D Ratio:

-

20

-

Distance between Tie Bars:

-

720x720 mm

-

Weight (KG):

-

5000 kg

-

Place of Origin:

-

Jiangsu, China

-

Open Stroke(mm):

-

420 mm

-

Model Number:

-

BST-4000

-

Brand Name:

-

U Tech

-

Power (kW):

-

37 kW

-

Warranty of core components:

-

2

-

Product name:

-

Plastic Products Injection Molding Machine

-

Name:

-

Plastic Making Injection Molding Machine

-

Application:

-

Injection Molding Machine Molds Change

-

Color:

-

Customzied

-

Advantage:

-

High efficiency

-

Material:

-

Stainless Steel 304 / 316L

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Product:

-

PET preform Injection Molding Machine

Product Description

Strong Technical design ability, Stable quality, and large production capability, Famous brand. Servo energy saving Injection Molding Machine, equipped with high performance servo motor controlling system, the machine's output power can vary in accordance with the loading changes,which reduce energy consumption and noise. The motor rotates at lower speed in holding pressure stage.

Machine Features:

1) Precision hydraulic synchronous template adjusting system.

2) Optimal design of high-strength, precision clamping unit.

3) Large screen, high precision machine computer system.

4) Optimized electric system.

5) Balanced type of double whole transfer oil cylinder.

6) Large torque oil motor.

7) High abrasion-resistant alloy sliding block.

8) The integrate type of detachable oil tank, magnetic filter and bypass strainer.

9) Reasonable and high efficient lubrication system.

10) Modularized energy conservation, high response oil-way system

Machine details

Configuration

|

S/N

|

Name

|

Brand

|

country

|

|

1

|

Main motor

|

ABB

|

Switzerland

|

|

2

|

Inverter

|

MITSUBISHI

|

Japan

|

|

3

|

PLC

|

OMRON

|

Japan

|

|

4

|

Touch screen

|

MITSUBISHI

|

Japan

|

|

5

|

Contactor

|

SCHNEIDER

|

France

|

|

6

|

Thermo- relay

|

SCHNEIDER

|

France

|

|

7

|

Air-break switch

|

SCHNEIDER

|

France

|

|

8

|

Proximity switch

|

TURCK

|

USA

|

|

9

|

Photoelectric switch

|

BANNER

|

USA

|

|

10

|

Air circuit system

|

SMC

|

Japan

|

|

11

|

Water pump

|

Southern

|

China

|

Other Injection product samples

The rigidity, orientation, discharging mechanism, positioning method, gap size and other factors should be considered in the design and parameter selection of die structure. The wearing parts on the mold should be easy to replace. For plastic mold and diecasting die, reasonable gating system, flow state of molten plastic or metal, position and direction of entering the cavity shouldalso be considered. The first mock exam is to increase the productivity and reduce the runner loss. A number of identical or different products can be completed in one mold at the same time. High efficiency, high precision and long life mold should be used in mass production.

Plastic injection moulds

Plastic bottle caps injection molding machine

Packing & Shipping

Why Choose Us

Plastic injection samples we produce

The rigidity, orientation, discharging mechanism, positioning method, gap size and other factors should be considered in the design and parameter selection of die structure. The wearing parts on the mold should be easy to replace. For plastic mold and die casting die, reasonable gating system, flow state of molten plastic or metal, position and direction of entering the cavity should also be considered. The first mock exam is to increase the productivity and reduce the runner loss.

The rigidity, orientation, discharging mechanism, positioning method, gap size and other factors should be considered in the design and parameter selection of die structure. The wearing parts on the mold should be easy to replace. For plastic mold and die casting die, reasonable gating system, flow state of molten plastic or metal, position and direction of entering the cavity should also be considered. The first mock exam is to increase the productivity and reduce the runner loss.

A number of identical or different products can be completed in one mold at the same time. High efficiency, high precision and long life mold should be used in mass production.

Certifications

FAQ

Q1:Do you have any reference project?

>> A1:We have reference project in most countries, and you can visit their factories if we get the permission of the customer.

Q2:What's your guarantee or the warranty of the quality if we buy your machines?

>>A2:We offer you high quality machines with 2 years guarantee . we will give u spare part free in 2 years.

Q3: Do you provide customized service?

>> A3: We will customize the machine according to your needs, material ,power,filling type,the kinds of the bottles and soon.

Q4:When can I get my machine after I paid?

>> A4:We will deliver the machines on time as the date we agreed both side.

Q5:How can I install my machine when it arrives?

>> A5:We will send our engineer to your side as soon as you get all your machines ready for testing and teaching your technician show to run the machines.

Hot Searches