- Product Details

- {{item.text}}

Quick Details

-

Dimensions(L*W*H):

-

4.8*2.25*3.2m

-

Weight:

-

6000 KG

-

printing material:

-

film, paper, non-woven

-

color:

-

eight colors

-

product name:

-

high speed 8 colors flexo rinting machine

-

Model number:

-

GYT series

-

Max. width of material:

-

1000mm

-

Max. width of printing:

-

960mm

-

printing speed:

-

5-50m/min

-

total power:

-

30KW

-

advantage:

-

high speed running, adopting angular gears, easy operation

-

function:

-

accurate color register

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

HAIXIN

-

Voltage:

-

380V(customized)

-

Dimensions(L*W*H):

-

4.8*2.25*3.2m

-

Weight:

-

6000 KG

-

printing material:

-

film, paper, non-woven

-

color:

-

eight colors

-

product name:

-

high speed 8 colors flexo rinting machine

-

Model number:

-

GYT series

-

Max. width of material:

-

1000mm

-

Max. width of printing:

-

960mm

-

printing speed:

-

5-50m/min

-

total power:

-

30KW

-

advantage:

-

high speed running, adopting angular gears, easy operation

-

function:

-

accurate color register

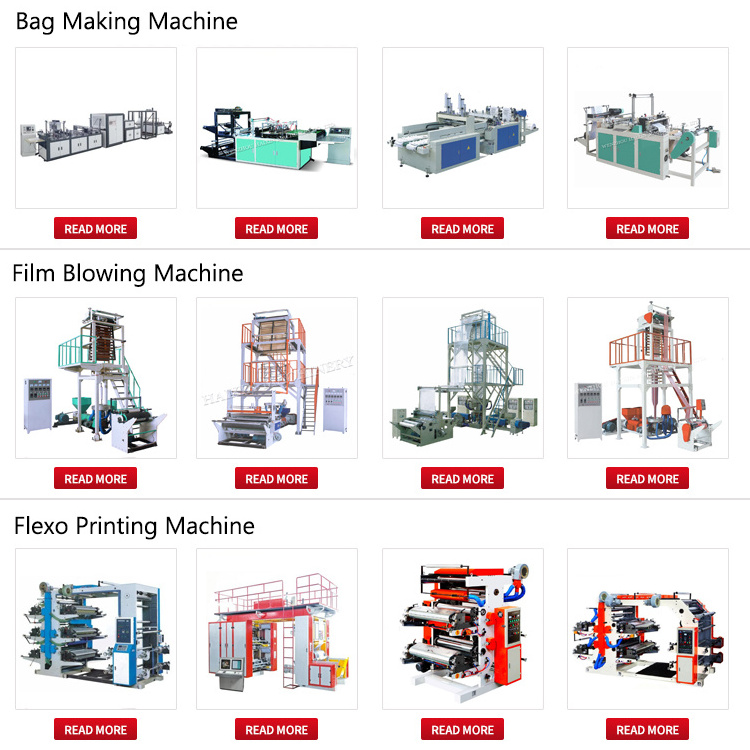

High speed 8 colors roll paper letterpress flexo printing machine for sale

GYT Series High Speed Flexographic Printing Machine

Introduction

This machine uses soft and photosensitive resin as printing plate, so called “flexographic printing machine”. It can print various packaging materials such as PE, PP, glass paper, roll paper and it is ideally for printing food package, supermarket handbag, vest bag and garment bag, etc.

Performance and Features

1.High speed and full load start up; stable running by tension control when increasing and decreasing speed, noise is decreased

2.High dots presentation rate under high speed; clear and vivid stratification of screen printing; strong stereo effect and accurate registering

3.Aluminum roller adopts the Japan semi-sealing small bearing; flinty oxidation, static and dynamic balancing treatments are conducted; low resistance and small flop

4.The angular gears adopted; accurate printing size and full printing specifications (5mm is a spec)

5.It has blowing and heating devices; the heating system adopts the central thermostatic control system and group management, also with the cold air forming devices

6.Printing rolls should keep moving while machine halted

7.Material holder use air shaft

8.Auto tension control

9.Unwind with auto deviation correction system (EPC)

10.Edge position control

Main Technical Variables

|

Printing width |

600mm |

800mm |

1000mm |

1200mm |

1400mm |

1600mm |

1800mm |

2000mm |

|

Printing color |

(PC: 8+0, 7+1, 6+2, 4+4) |

|||||||

|

Printing length |

7.5# - 40# |

|||||||

|

Printing plate lifting system |

Pneumatic/Hydraulic pree control |

|||||||

|

Mechanical speed |

80m/min |

|||||||

|

Printing speed |

60m/min |

|||||||

|

Anilox cylinder |

ceramic anilox roller 50-1000LPI |

|||||||

|

Register precision |

Longitude:±0.25mm, Transerse:±0.25mm |

|||||||

|

Rewinder/unwinder dia |

φ750 (depends on your need) |

|||||||

|

Master motor |

3.7kw |

3.7kw |

5.5kw |

5.5kw |

7.5kw |

7.5kw |

11kw |

11kw |

|

Unwinder powder brake |

5kg |

10kg |

20kg |

40kg |

||||

|

Rewinder motor |

1.5kw |

1.5kw |

2.2kw |

3.0kw |

||||

|

electrical heater |

20kw |

22kw |

24kw |

26kw |

28kw |

30kw |

32kw |

34kw |

|

Blower of heater(kw) |

1.5*2 |

1.1*4 |

1.1*4 |

1.1*4 |

1.5*4 |

1.5*4 |

2.2*4 |

2.2*4 |

|

Centrifugal blower(kw) |

0.37 |

0.37 |

0.55 |

0.75 |

1.1 |

1.1 |

1.5 |

1.5 |

|

Inking motor(kw) |

0.37 |

0.37 |

0.37 |

0.37 |

0.75 |

0.75 |

0.75 |

0.75 |

|

Master frequency converter |

DELTA (TAIWAN) |

|||||||

|

Bearing |

MADE IN CHINA |

|||||||

|

Unilateral bearing |

MADE IN CHINA |

|||||||

|

Net weight(kg) |

5500 |

5750 |

6000 |

6250 |

6500 |

6750 |

7000 |

7300 |

|

Total power |

26kw |

28kw |

30kw |

33kw |

37kw |

40kw |

42kw |

46kw |

|

Dimension (L*W*H) |

4800 * 1850 * 3200mm |

4800 * 2050 * 3200mm |

4800 * 2250 * 3200mm |

4800 * 2450 * 3200mm |

4800 * 2650 * 3300mm |

4800 * 2850 * 3300mm |

4800 * 3050 * 3300mm |

4800 * 3250 * 3300mm |

1.We welcome the customers to visit the factory and we will pick you up.

2.Our machines use famous brand parts and test every part of the machine in the process of production.

3.Our engineers can install machines for you, and we can also train your employees until they can operate the machine independently. Of course, you can learn and install in our factory

4.We can provide a warranty of 14 months. If the machine has a non-human failure (except for vulnerable parts), we will provide you with a maintenance plan.

5.Welcome to send us an inquiry