- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

2%

-

CrO Content (%):

-

0

-

SiC Content (%):

-

0

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

TKCLB

-

Brand Name:

-

TK BRICKS

-

Fe2O3 %:

-

2.5 max

-

Refractoriness ℃::

-

1740 min

-

Refractoriness under load (0.2MPa) ℃::

-

1350 min

-

Apparent porosity %:

-

24 max

-

Cold crushing strength Mpa:

-

30 min

-

Application:

-

Insulation,refractory LINER

-

Size:

-

230*114*65mm or customized

-

Advantage:

-

high temperature mechanics and chemical corrosion resista

-

Bulk density g/cm3:

-

2.3-2.4kg/m3

-

Certificate:

-

ISO BV

Quick Details

-

SiO2 Content (%):

-

50%~65%

-

Al2O3 Content (%):

-

38-42%

-

MgO Content (%):

-

0.8-1.2

-

CaO Content (%):

-

2%

-

CrO Content (%):

-

0

-

SiC Content (%):

-

0

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

TKCLB

-

Brand Name:

-

TK BRICKS

-

Fe2O3 %:

-

2.5 max

-

Refractoriness ℃::

-

1740 min

-

Refractoriness under load (0.2MPa) ℃::

-

1350 min

-

Apparent porosity %:

-

24 max

-

Cold crushing strength Mpa:

-

30 min

-

Application:

-

Insulation,refractory LINER

-

Size:

-

230*114*65mm or customized

-

Advantage:

-

high temperature mechanics and chemical corrosion resista

-

Bulk density g/cm3:

-

2.3-2.4kg/m3

-

Certificate:

-

ISO BV

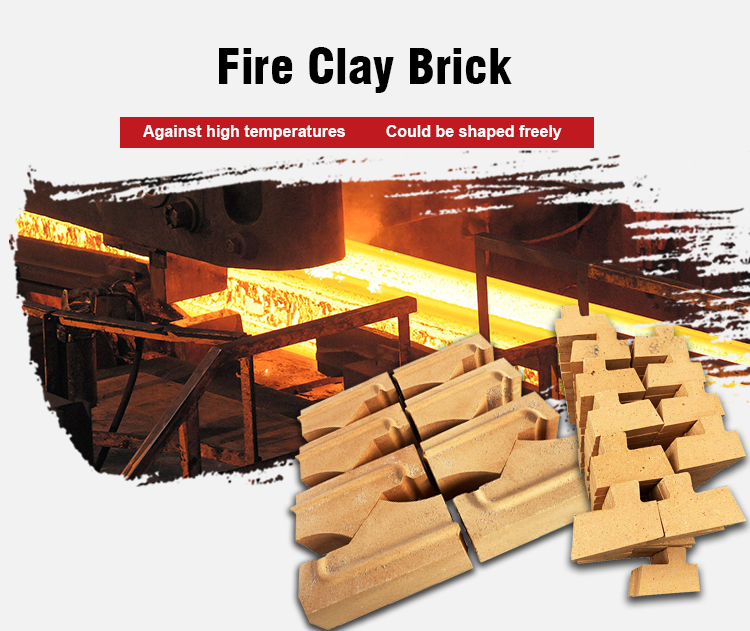

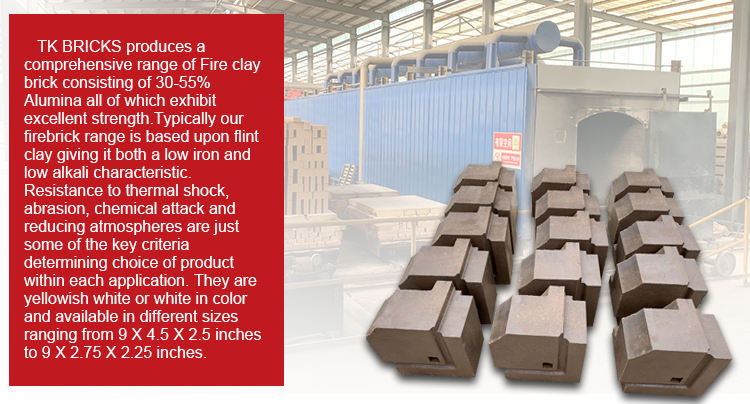

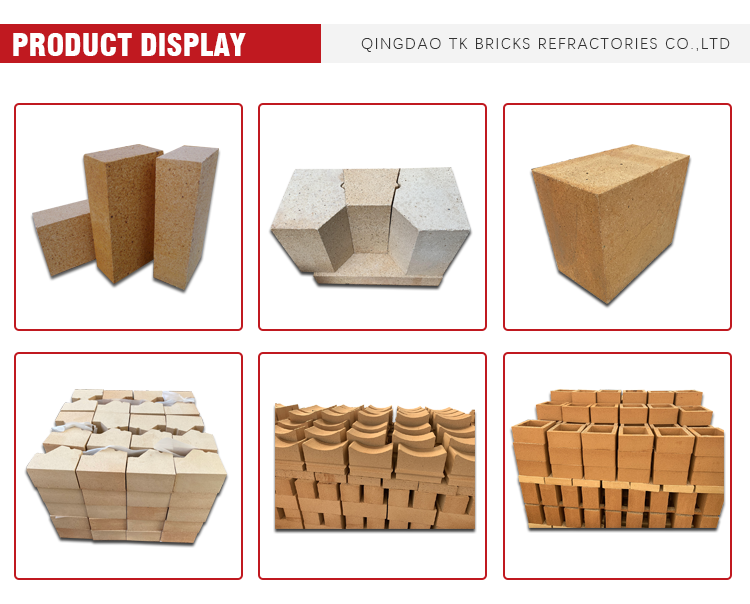

Lower Price High Alumina Refractory Fire Clay Thermal Insulating Brick 230x114x15 Mm 230x114 For Furnace Lining

Fire clay brick is a special type of brick made using fire clay and has a good resistance against high temperatures which are used

in kilns, lining furnaces, fireplaces and fireboxes. These bricks are manufactured in a way similar to that of normal bricks,

except during the burning process- Fire bricks are exposed to very high temperatures

The refractoriness of the brick is more than 1580℃.

in kilns, lining furnaces, fireplaces and fireboxes. These bricks are manufactured in a way similar to that of normal bricks,

except during the burning process- Fire bricks are exposed to very high temperatures

The refractoriness of the brick is more than 1580℃.

|

ITEM

|

Low Porosity Fire Clay Bricks

|

|

|

|

|||

|

|

DN-10

|

DN-12

|

DN-15

|

DN-17

|

|||

|

Al2O3/%

|

≥46

|

≥45

|

≥42

|

≥40

|

|||

|

Fe2O3/%

|

≤1.1

|

≤1.2

|

≤1.5

|

≤2.0

|

|||

|

Bulk density/g/cm3

|

≥2.40

|

≥2.37

|

≥2.30

|

≥2.25

|

|||

|

Refractoriness/ ℃

|

≥1700

|

≥1690

|

≥1750

|

≥1770

|

|||

|

Refractoriness under Load/KD ℃

|

≥1520

|

≥1500

|

≥1470

|

≥1420

|

|||

|

Permanent Linear Change/%

|

1400℃×2h

+0.0

|

1400℃×3h

+0.05~-0.10

|

1400℃×3h

+0.1~-0.2

|

1400℃×2h

|

|||

|

Apparent Porosity/%

|

≤10

|

≤12

|

≤15

|

≤17

|

|||

|

Cold crushing strength/Mpa

|

≥65

|

≥65

|

≥55

|

≥50

|

|||

|

Fire Clay Bricks SK SERIES

|

|

|

|

|

||||

|

ITEM

|

SK30

|

SK32

|

SK34

|

SK35

|

||||

|

Al2O3/%

|

33%

|

38%

|

42%

|

48%

|

||||

|

Fe2O3/%

|

≤3

|

≤3

|

≤3

|

≤2.5

|

||||

|

Refractoriness/ ℃

|

≥1690 °C

|

≥1730 °C

|

≥1750 °C

|

≥1750 °C

|

||||

|

Bulk density/g/cm3

|

1.9-2.0

|

2.0-2.1

|

2.1-2.18

|

2.15-2.3

|

||||

|

Unit weight (230*114*65mm)

|

≥3.35KGS

|

≥3.55KGS

|

≥3.65KGS

|

≥3.75KGS

|

||||

|

Apparent porosity/%

|

≤26

|

≤24

|

≤24

|

≤22

|

||||

|

Cold crushing strength

|

≥20Mpa

|

≥25Mpa

|

≥30Mpa

|

≥35Mpa

|

||||

|

Refractoriness under load/ ℃

|

≥1250 °C

|

≥1300 °C

|

≥1350 °C

|

≥1420 °C

|

||||

|

Reheating Linear Change/%

|

0~ -0.5

(1350°C,2h)

|

0~ -0.3

(1350°C,2h)

|

0~ -0.4

(1450°C,2h)

|

+0.1~ -0.4

(1450°C,2h)

|

||||

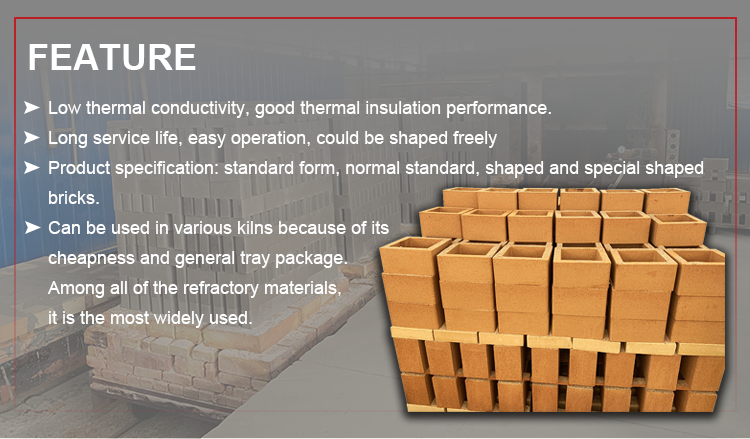

Also, we have SK36, SK37, SK38, SK40 refractory

high alumina bricks to choose. Their aluminum content is higher than fire clay bricks, and the use temperature is higher. If your

kiln needs higher temperature and longer service life, suggest you choose refractory high alumina bricks.

Hot Searches