- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±1% Silicone Filling Machine

-

Voltage:

-

220V/380V 50-60Hz Silicone Filling Machine

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

MIC Silicone Filling Machine

-

Dimension(L*W*H):

-

2300*1400*2500mm Silicone Filling Machine

-

Weight:

-

2500 KG

-

Name:

-

Silicone Sealant Filling Machine Silicone Filling Machine

-

Function:

-

Filling Sealing Silicone Filling Machine

-

Material:

-

Stainless Steel 304/316 Silicone Filling Machine

-

Bottle type:

-

Cartridge Silicone Filling Machine

-

Feature:

-

Work Efficiently Silicone Filling Machine

-

Air Consume:

-

0.3 m³ /min Silicone Filling Machine

-

Filling volume:

-

MAX 310ML Silicone Filling Machine

-

Air Supply:

-

0.5-0.7MPa Silicone Filling Machine

-

Capacity:

-

1000-2000BPH Silicone Filling Machine

-

Filling Liquid:

-

Stick Silicone Silicone Filling Machine

-

Marketing Type:

-

Hot Product 2022

Quick Details

-

Machinery Capacity:

-

Other, 400BPH, 500BPH, 2000BPH, 1000BPH, 100BPH, 200BPH, Silicone Filling Machine

-

Packaging Material:

-

Plastic, Wood, Silicone Filling Machine

-

Filling Material:

-

Other, Silica Gel , Super Glue, Grease, Silicone Sealant., Silicone Filling Machine

-

Filling Accuracy:

-

±1% Silicone Filling Machine

-

Voltage:

-

220V/380V 50-60Hz Silicone Filling Machine

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

MIC Silicone Filling Machine

-

Dimension(L*W*H):

-

2300*1400*2500mm Silicone Filling Machine

-

Weight:

-

2500 KG

-

Name:

-

Silicone Sealant Filling Machine Silicone Filling Machine

-

Function:

-

Filling Sealing Silicone Filling Machine

-

Material:

-

Stainless Steel 304/316 Silicone Filling Machine

-

Bottle type:

-

Cartridge Silicone Filling Machine

-

Feature:

-

Work Efficiently Silicone Filling Machine

-

Air Consume:

-

0.3 m³ /min Silicone Filling Machine

-

Filling volume:

-

MAX 310ML Silicone Filling Machine

-

Air Supply:

-

0.5-0.7MPa Silicone Filling Machine

-

Capacity:

-

1000-2000BPH Silicone Filling Machine

-

Filling Liquid:

-

Stick Silicone Silicone Filling Machine

-

Marketing Type:

-

Hot Product 2022

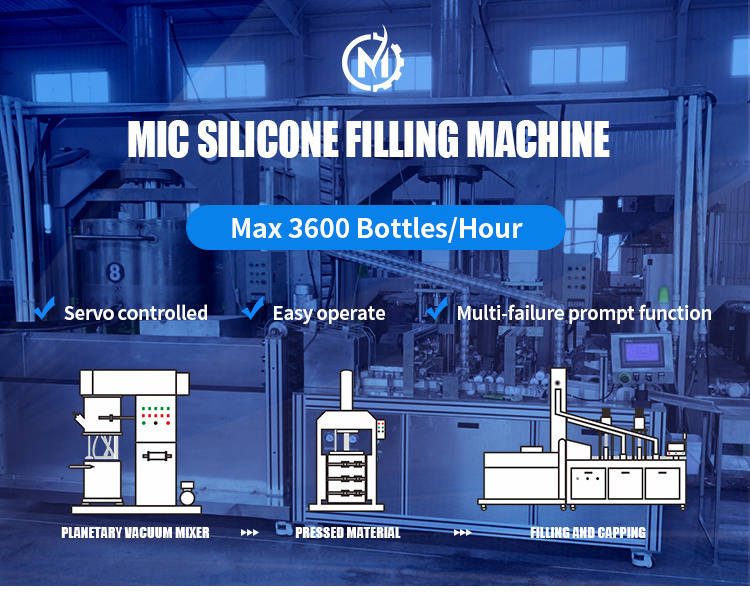

We have different kinds of sealant filling machine

For machine, we have horizontal, vertical, semi automatic(we have double filling system for AB type) and Automatic, for package, we have cartridge( we have single cartridge, two component), soft film.

— TECHNICAL PARAMETER —

|

Type

|

XG-1

|

XG-2

|

M30

|

M60

|

SJG-1

|

||||

|

Power Supply

|

220V/380V 50-60Hz

|

220V/380V 50-60Hz

|

220V/380V 50-60Hz

|

220V/380V 50-60Hz

|

220V/380V 50-60Hz

|

||||

|

Capacity

|

20pcs/min

|

50-55pcs/min

|

10-30pcs/min

|

30pcs/min

|

20pcs/min

|

||||

|

Max volume

|

600ml

|

600ml

|

600ml

|

600ml

|

1000ml

|

||||

|

Package type

|

Cartridge

|

Plastic cartridge

|

Plastic cartridge

|

Plastic cartridge

|

Soft film

|

||||

|

Filling method

|

Servo motor

|

Servo motor

|

Air cylinder

|

Servo motor

|

Servo motor

|

||||

|

Dimensions(L×W×H)

|

1100*800*1600mm

|

4200*1450*2200mm

|

1200*1000*1800mm

|

1150*1000*1660mm

|

1950*1150*1950mm

|

||||

|

Weight(kg)

|

500KG

|

850KG

|

650KG

|

850KG

|

650KG

|

||||

— MACHINE APPLICATION —

Can be used to fill different kinds of sealant, adhesive and paste.

It is suitable for small volume cartridge packing, and it widely used in chemical industrial.

— REAL PHOTO SHOW —

— FAQ —

Q1.Are you trading company or manufacturer ?

>> We are factory. Our factory is located in Changzhou near Shanghai.

Q2.What is the payment of your company?

>> 100% T/T, 30% of prepaid contracts entered into force, 70% paid before delivery. L/C is supported also.

Q3.Do you provide a complete production line and customized services?

>> We are a company that provides a complete production line. We can design the machine according to your requirements (material, power, filling type, bottle type, etc), and we will give you our professional advice. As you know, we have beenin this industry for many years.

Q4.If we buy your machine, what is your guarantee or quality assurance?

>> We provide you with high- quality machines with 1 year warranty and lifetime technical support.

Q5.How long does it take to install?

>> According to your machine order, we will send one or two engineers to your factory, about 10 days. Customers need to provide round-trip air tickets, visa fees, local transportation, accommodation, food, 120 US dollars/ day / person.

Q6.What kind of after-sales service is provided?

>> After the production is completed, we will debug the production line, take photos, video and send to customers via email or instant tools. After the commissioning is completed, we will package and ship the equipment according to the standard export packaging. Operating manuals will be sent with machine or by email. According to the customer' s requirements, we can arrange our engineers to the customer's factory for installation and training. Engineers, sales managers, and after-sa les service managers form an after-sales team to follow up on customer projects online and offline.

Hot Searches