- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

SND

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

3600*1700*1800

-

Power (kW):

-

37

-

Weight (T):

-

8

-

Stationary Cutter:

-

25

-

Rotary cutters:

-

25

-

POWER:

-

37*2

-

WRIGHT:

-

6-8T

-

Crushing caliber(mm):

-

1000*850

-

speed:

-

10-15rpm/min

-

Capacity (kg/h):

-

2000-3000

Quick Details

-

Max.Production Capacity (kg/h):

-

3000

-

Place of Origin:

-

Zhejiang, China

-

Production Capacity (kg/h):

-

2000 - 3000 kg/h

-

Brand Name:

-

SND

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

3600*1700*1800

-

Power (kW):

-

37

-

Weight (T):

-

8

-

Stationary Cutter:

-

25

-

Rotary cutters:

-

25

-

POWER:

-

37*2

-

WRIGHT:

-

6-8T

-

Crushing caliber(mm):

-

1000*850

-

speed:

-

10-15rpm/min

-

Capacity (kg/h):

-

2000-3000

Product Overview

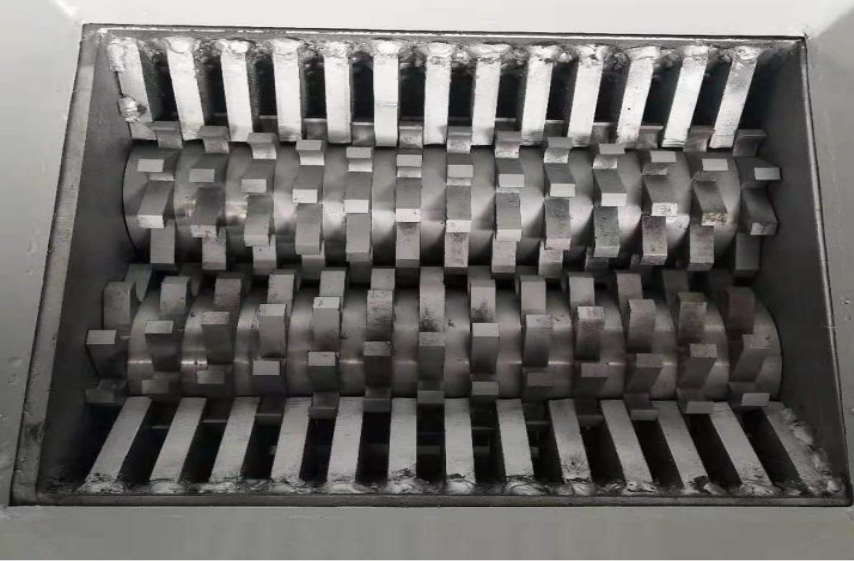

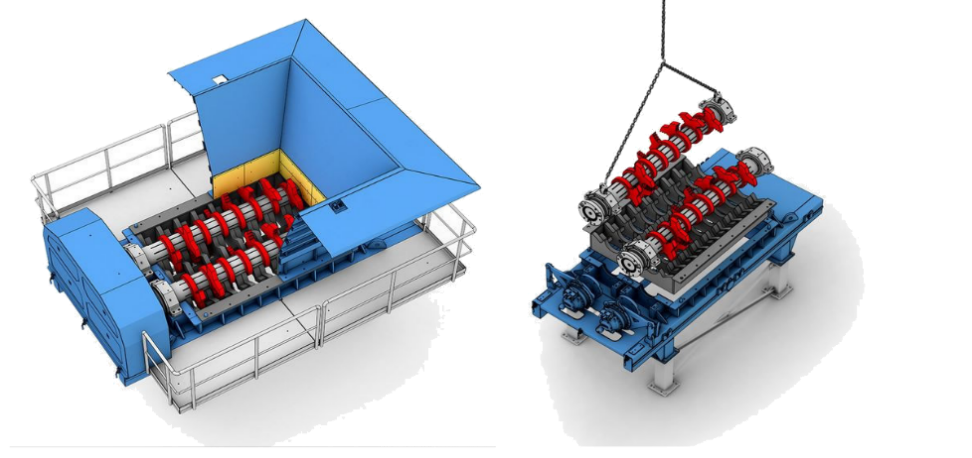

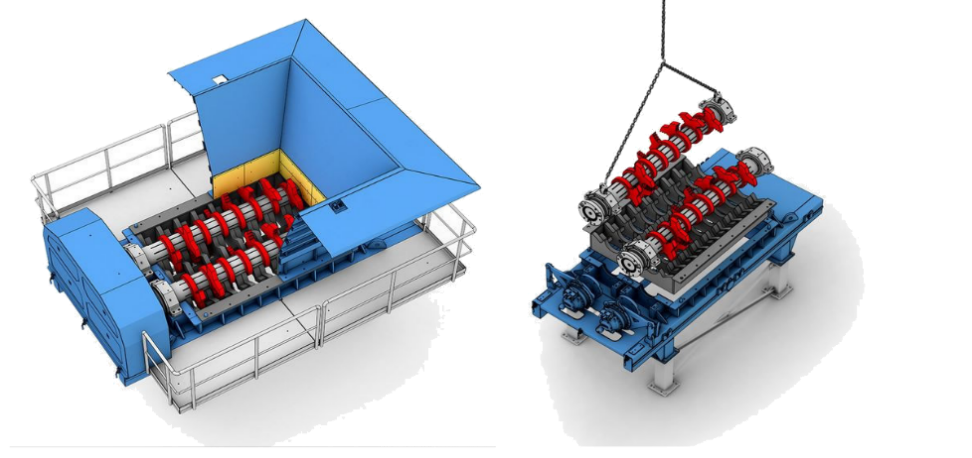

Structural characteristics of dual shaft shredder

1. Crusher main body: The main body of the equipment is welded with high-quality steel plates for stress relief treatment/overall machining, ensuring the stability of the equipment under long-term heavy load.

2.Moving knife/fixed knife: The material of the moving knife is made of special alloy tool steel forged blanks, precision machining, multiple heat treatments, and low-temperature freezing heat treatment technology. The overall toughness and hardness are consistent, and it can be repeatedly repaired and used, ensuring cutting performance and service life. The fixed tool adopts a patented hook type installation, which optimizes the tool replacement function and makes tool maintenance and replacement more efficient.

3. Bearing/seal: The bearing seat adopts a patented split and removable type, which can quickly remove components such as moving knives, stationary knives, bearings, etc., making it easy to maintain and replace knives. The unique sealing structure effectively blocks the contact of debris and grease, and can also protect bearings and gears when handling liquid materials.

4. Cutter shaft: It is processed and refined with high-strength heavy-duty special steel, which more reasonably cooperates with the cutter to provide powerful power for cutting.

Product advantages of dual shaft shredder

1. Movable knife with high crushing power, all of which are made of alloy steel and have a strong and long service life.

2. The frame plate is thick, resistant to high torque, and very sturdy.

3. Adopt microcomputer (PC) automatic control, with start, stop, reverse and overload automatic reverse control functions.

4. The equipment features low rotational speed, large torque, low noise, and dust that can meet environmental standards.

5. Easy to adjust, low maintenance cost, economical and durable.

The thickness of the tool and the number of claws can be changed according to different materials.

Working principle

Working principle of dual shaft shredder

The dual shaft shredder is a slow running high torque dual shaft crusher. The material enters the inside of the box through the feeding system, and is collected by two rotor shafts that are loaded on the box. The two shafts alternately rotate inward or outward with each other. Each shaft is equipped with a row of specially shaped shredding blades. The material undergoes a comprehensive process of shearing, squeezing, and tearing with a shredding blade to shred into small pieces of material that are discharged from the lower part of the box.

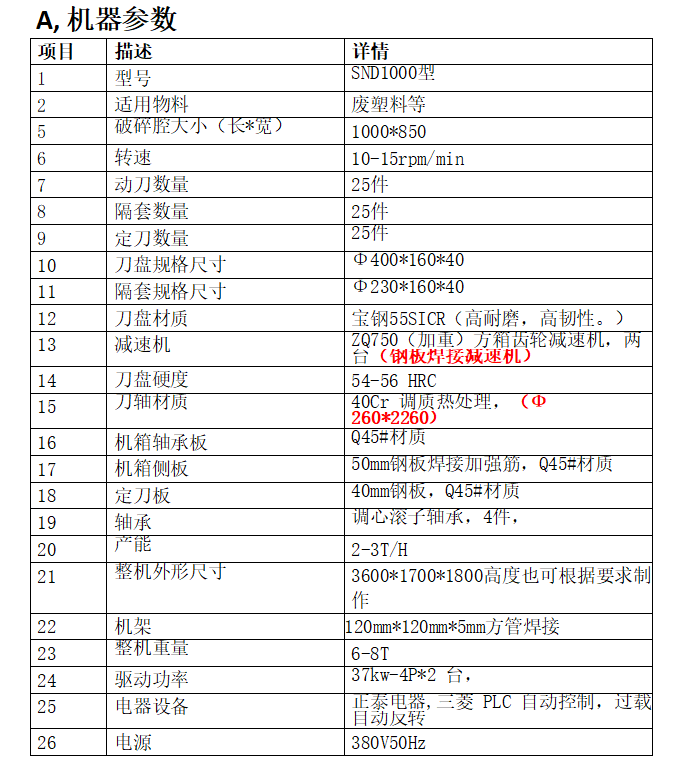

PRODUCT SPECIFICATIONS

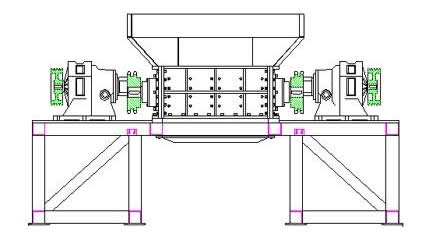

Machine Structure Diagram

PRODUCT CONFIGURATION

SIMILAR PRODUCTS

Hot Searches