- Product Details

- {{item.text}}

Quick Details

-

Power:

-

15KW

-

Dimension(L*W*H):

-

2800*750*1200mm

-

Weight (KG):

-

850

-

Product name:

-

rebar straightening and cutting machine

-

Applicable rebar diameter:

-

Round rebar: 4-14mm Screw rebar: 4-12mm

-

Motor power:

-

7.5Kw

-

Traction motor:

-

3KW

-

Cutting motor:

-

4KW

-

Straightening rate:

-

55m/min

-

Min cutting length:

-

30cm

-

Dimension:

-

2800*750*1400mm

-

Weight:

-

850Kg

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YG/YUGONG

-

Voltage:

-

380V, 380v 50hz / customize

-

Power:

-

15KW

-

Dimension(L*W*H):

-

2800*750*1200mm

-

Weight (KG):

-

850

-

Product name:

-

rebar straightening and cutting machine

-

Applicable rebar diameter:

-

Round rebar: 4-14mm Screw rebar: 4-12mm

-

Motor power:

-

7.5Kw

-

Traction motor:

-

3KW

-

Cutting motor:

-

4KW

-

Straightening rate:

-

55m/min

-

Min cutting length:

-

30cm

-

Dimension:

-

2800*750*1400mm

-

Weight:

-

850Kg

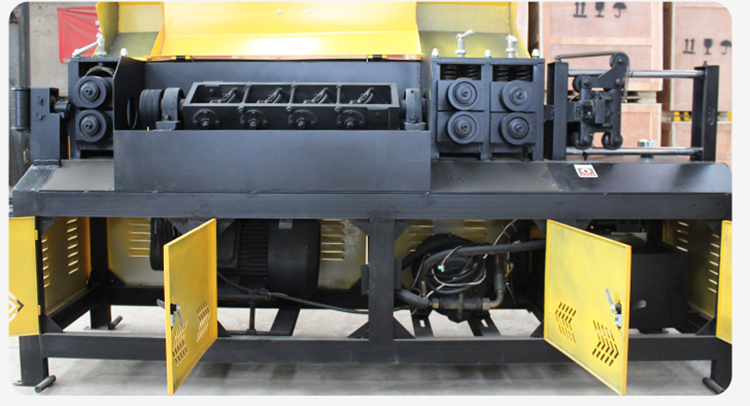

Steel bar straightening and cutting machine

The steel bar straightening and cutting machine is a tool specially used for steel bar cutting. It is one of the indispensable equipment for steel bar processing. It’s mainly used for fixed length cutting of steel bars in housing construction, bridges, tunnels, power stations, large-scale water conservancy and other projects. Compared with other cutting equipment, it has the characteristics of light weight, low energy consumption, reliable work and high efficiency.

|

Model |

YGT Q - 1 0 |

YGT Q - 1 2 |

YGT Q - 1 4 |

|

Applicable rebar diameter |

Round rebar: 4-1 0 mm Screw rebar: 4-8mm |

Round rebar: 4-1 2 mm Screw rebar: 4- 10 mm |

Round rebar: 4-1 4 mm Screw rebar: 4- 12 mm |

|

M otor power |

7.5 kw |

9kw |

7.5kw |

|

Traction motor |

/ |

/ |

3kw |

|

Cutting motor |

/ |

/ |

4kw |

|

Voltage |

380v 50hz / customize |

380v 50hz / customize |

380v 50hz / customize |

|

Straightening rate |

45-50m/min |

5 5 m/min |

5 5 m/min |

|

Cutting error |

± 5mm |

± 5mm |

± 5mm |

|

Min cutting length |

20-30cm |

30cm |

30cm |

|

Weight |

240 kg |

320kg |

850KG |

|

Dimension |

1400×570×900mm |

1680×630×1050 mm |

2800×750×1400 mm |

Main features and advantages :

1. Microcomputer control,automatic straightening,automatic fixed length,automatic cutting.

2. Very easy operation.

3. multiple batches of simultaneous input length and quantity, computer storage memory.

4. Hydraulic {double tube double knife) cut off, no card cutter, more precise and quieter.

5. Smooth operation, low failure rate, easy maintenance and cheap accessories.

6. It occupies a small area and easy to move and install. The remote control starts and stops within 30m.

Product details :

Construction Site:

1. Packaging:

1)Wrapped by protective film;

2)Packed by standard import & export wooden cases or carton boxes.

2. Shipping:

By logistics; by automobile; by train; by shipping; by air etc.