- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

200*100*60 mm, 240*115*90 mm, 200*200*60 mm, 230*220*115 mm, customized

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YZ

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

3100*1100*1300mm

-

Weight (KG):

-

220 kg

-

Name:

-

clay brick extruder machine clay brick making machine video

-

Raw material:

-

Clay ,shale, coal gangue, fly ash

-

Block Type:

-

Solid Block

-

Product Name:

-

clay brick making machine price in India

-

part 1:

-

main extruder strip cutting machine and blank cutting machine

-

part 2:

-

strip cutting machine

-

Part 3:

-

blank cutting machine

-

Related machine 1:

-

manual cement hollow brick making machine

-

Related machine 2:

-

small manual clay brick making machine

-

Certification:

-

ISO

Quick Details

-

Type:

-

red clay solid brick making machine line

-

Brick Raw Material:

-

Clay

-

Production Capacity (Pieces/8 hours):

-

12000pcs per day

-

Brick size:

-

200*100*60 mm, 240*115*90 mm, 200*200*60 mm, 230*220*115 mm, customized

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YZ

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

3100*1100*1300mm

-

Weight (KG):

-

220 kg

-

Name:

-

clay brick extruder machine clay brick making machine video

-

Raw material:

-

Clay ,shale, coal gangue, fly ash

-

Block Type:

-

Solid Block

-

Product Name:

-

clay brick making machine price in India

-

part 1:

-

main extruder strip cutting machine and blank cutting machine

-

part 2:

-

strip cutting machine

-

Part 3:

-

blank cutting machine

-

Related machine 1:

-

manual cement hollow brick making machine

-

Related machine 2:

-

small manual clay brick making machine

-

Certification:

-

ISO

It is widely used in small family brick owners.Suitable for family workshops.

Also, its compact design makes machine operation very easily

1.Strong applicability, lower energy consumption,the extruder only 11 KW.

2.The raw material for making bricks can be soil,mud.

3.Solid brick is the best choice.

4.The brick extruder has taken manual brick strip cutter and brick blank cutter.

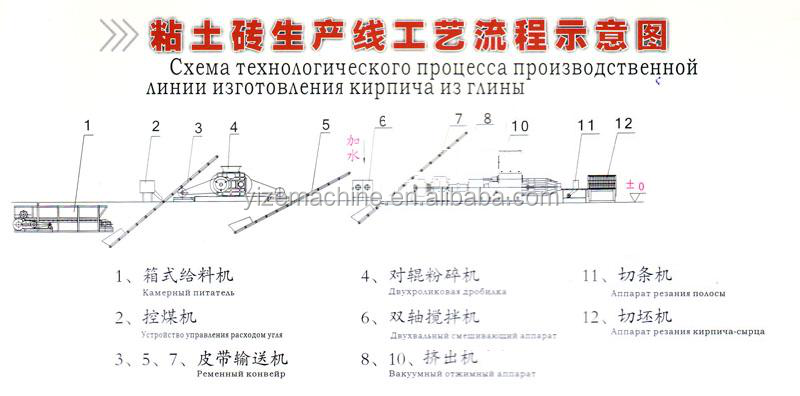

1.Send clay raw material to box feeder with loader. Send the clay raw material to double-roll crusher for preliminary crushing

2.Preliminary crushed material is conveyed to twin-shaft mixing machine for adding water and agitating through belt conveyer.

1.The molding water content rate should be controlled within 16%-18%.

2.The vacuum pump will take out the air that entered into the extruding machine together with pug. The vacuum extruder will

extrude the pug from machine mouth and then, carry out slitting & parting according to the required dimension.

1.When the unfired bricks cut by cutter and arranged into groups. clay brick machine

2.The drying chamber work system has heating system, regulating system and moisture excluding system. The drying quality is controlled by regulating system.

1.After drying , the unfired bricks are sent onto kiln by the dried brick cart,stacking bricks onto the kiln car for burning.

2.unloading system The properly burned bricks .

|

Model

|

Motor

|

Capacity

|

Dimension

|

|

YZZJ-250

|

11kw

|

10000-12000pcs/8h

|

3100*1000*1300mm

|

|

YZZJ-300

|

30kw

|

40000-50000pcs/8h

|

2000*1000*1200mm

|

|

YZZJ-400

|

55kw

|

80000-100000pcs/8h

|

2300*1200*1300mm

|

It is one model of all in one . extruder--cutter -slitter

Can use motor or Diesel engine .

YZZJ300model extruder --automatic cutter--automatic strip cutting machine.

Whole line including 11machines

1.Feeder machine 2.conveyor 3.Roller crusher 4.double-shaft mixer 5.400 model vacuum brick machine 6.Vacuum pump 7.Air compressor

8.Automatic cutter 9.Automatic slitter 10.Fall plate machine 11 Control electrical cabinet

We are the supplier of the Trade Assurance amount guaranteed by Alibaba, your payment will be 100% protected, the following is our Trade Assurance Transaction History:

Zhengzhou Yize engaged in a wide range of machine business, We are in this line for more than 10 years. We provide best quality machines and solutions for global users in machinery fields. Some of them also visit us and check our machines. From the single machine to the automatic product line, From china to the whole world. Zhengzhou Yize committed to machine manufacturing and high efficiency producing. We also have development on new material and key technology. We welcome you to visit us and make a deal.

|

MOQ

|

Usually 1 set, or based your order, Preferential wholesale price.

|

|

Voltage

|

110V /220V /380V /415V, 50/60 HZ Single/Three phase , Customize the voltage according to your local voltage.

|

|

Guarantee

|

Quality guarantee term is for one year, During guarantee period, free technical support and free spare parts supply.

|

|

Payment term

|

T/T, Credit card, Western Union, RMB , Alipay, Wechat, Cash, E-checking, MoneyGram, L/C, etc.

|

|

Documents offer

|

By express:express waybill

By air:airway bill By sea:B/L, commercial invoice, packing list, sales contract, CO, FE, FTA or as your request. |

|

How to install and maintain the machine

|

we can teach you install or maintain the machine by video, email ,pictures.....if large project , we can arrange our engineer help you to install or maintain it in your country. If you need spare parts, we can supply for free or cost price, you pay express cost.

|

|

Assignment of engineers and training

|

we can supply manual book, work video, install video, pictures first, we can also assign our engineers to go abroad for installing or training machines for our users.

|

Service before sale

1.One-on-one exclusive customer service staff, 24 hours online.

2.Inquiry, email, message will be replied at first time.

3.Supply professional technical parameters, video picture sharing, project design.

Service on sale

1.Ensure customer payment security.

2.Ensure the customer's price is stable and reasonable.

3.Insist on quality first the production standard, every machine before leave the factory we test it ensure the quality is good.

Service after sale

1.Arrange high-efficiency delivery and safe transport.

2.Supply installation training, direction for use, maintenance instructions, techinical support, all necessary documents you need and oversea service.