- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.7-1.2mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Jane

-

Voltage:

-

380V 50HZ 3P or Customize as customer' request

-

Dimension(L*W*H):

-

4200*800*1000mm

-

Weight:

-

2500 kg

-

Feeding width:

-

300mm or customer's need

-

Marketing Type:

-

Hot Product

-

Product name:

-

Rolling shutter door

-

Color:

-

Client's Request

-

Control system:

-

PLC(imported Brand)

-

Roller material:

-

45# Forged Steel

-

Shaft material:

-

High Grade No.45 Forged

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Suitable to process:

-

Color Steel or Aluminum

-

Usage:

-

Shutter Door Making Machine

-

Screen:

-

Color touch screen

-

Cutting type:

-

Hydraulic Cutting

Quick Details

-

Type:

-

Roll forming machine

-

Tile Type:

-

Color Steel or Aluminum

-

Production Capacity:

-

8-20m/min

-

Rolling thinckness:

-

0.7-1.2mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Jane

-

Voltage:

-

380V 50HZ 3P or Customize as customer' request

-

Dimension(L*W*H):

-

4200*800*1000mm

-

Weight:

-

2500 kg

-

Feeding width:

-

300mm or customer's need

-

Marketing Type:

-

Hot Product

-

Product name:

-

Rolling shutter door

-

Color:

-

Client's Request

-

Control system:

-

PLC(imported Brand)

-

Roller material:

-

45# Forged Steel

-

Shaft material:

-

High Grade No.45 Forged

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Suitable to process:

-

Color Steel or Aluminum

-

Usage:

-

Shutter Door Making Machine

-

Screen:

-

Color touch screen

-

Cutting type:

-

Hydraulic Cutting

Products Description

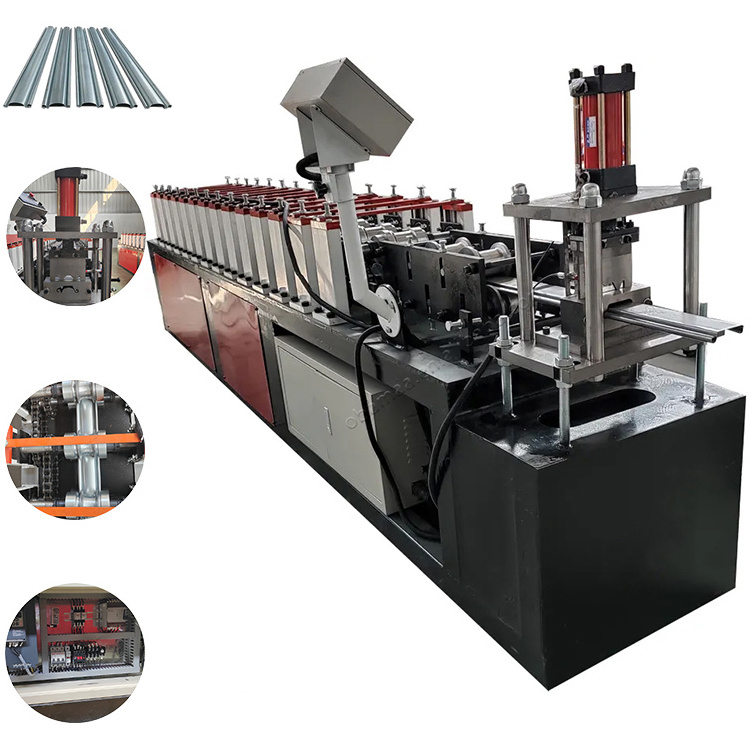

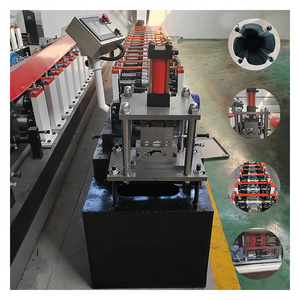

Rolling Shutter Door Machine

The metal rolling shutter door rolling forming machine is mainly used for producing shutter doors, suitable for places such as garages, workshops, warehouses, etc. We produce and supply various roller shutter forming machines. Our fully automated machine is a compact and fast operator that can continuously reduce space and increase production.

Work processing

Processing Flow

Uncoiling → Feeding material into machine →Roll forming → Auto cutting →Products receiving table

Specification

|

Rolling Shutter Door Machine

|

|

|

|

|||

|

SN

|

Part details

|

Item

|

Specification

|

|||

|

1

|

Material

|

Raw material

|

Colored Steel

|

|||

|

|

|

Thickness

|

0.7-1.2 mm

|

|||

|

2

|

Machine

|

Roller station

|

Depend on customer' drawing

|

|||

|

|

|

Shaft diameter

|

55mm

|

|||

|

|

|

Solid shaft material

|

High grade 45# steel

|

|||

|

|

|

Roller material hardness 30-40 HRC

|

Cr 12

|

|||

|

|

|

Machine size

|

4200*800*1000mm

|

|||

|

|

|

Machine weight

|

About 2.5 ton

|

|||

|

|

|

Machine color

|

As customer' request

|

|||

|

|

|

Working speed

|

8-20 m/min

|

|||

|

3

|

Power

|

Driving way

|

Chain 1 inch

|

|||

|

|

|

Main power

|

4 kw

|

|||

|

|

|

Pump power

|

3kw

|

|||

|

|

|

Voltage

|

Customize as customer' request

|

|||

|

4

|

Decoiler

|

Operation

|

Manual

|

|||

|

|

|

Weight capicatity

|

5 ton

|

|||

|

|

|

Price

|

Free as gift

|

|||

|

5

|

Receiving table

|

Operation

|

Manual

|

|||

|

|

|

Length

|

3 m

|

|||

|

|

|

Price

|

Free as gift

|

|||

Product Details

Feeding Device

1. 2 stainless steel rollers protect raw material surface.

2. With hand wheels easy adjust for feeding different thickness raw material.

3.the platform width is adjustable by hand wheel, have the bearing inside to protect the edge of the steel sheet.

Roll Forming Device

1.GCr12 quenched, Anti -Corrosion,Increase Hardness, Ensure The Precision And Good Abrasion Performance.

2. Each roller has number and with keynotes, it can fix on the shaft stable.

Hydraulic cutting

1.Controlled by oil pump.

2.Automatic cutting as target products length Blade material: Cr12, quenching treatment.

3.Hardness:

50-65 HRC.

4.Cutting tolerance:

± 1 mm.

PLC control system

1.PLC brand : Delta or Siemens.

2.Inverter brand: Delta .

2.Inverter brand: Delta .

3.Low electric part: Schneider.

4.Encoder: OMRON.

4.Encoder: OMRON.

5.

Screen:

Touchable screen.

6.Adopted aviation plugs,easy installation.

7.Full automatic easy operation. 8.Operation language:English(it can also customized language for our customer).

9.National coinsurance,spar parts Brand Siemens and Schneider.

6.Adopted aviation plugs,easy installation.

7.Full automatic easy operation. 8.Operation language:English(it can also customized language for our customer).

9.National coinsurance,spar parts Brand Siemens and Schneider.

Pump station

1.The hydraulic oil station is equipped with 2 solenoid valves and a 5.5kw high-power motor to match the high intensity operation of the machine.

2.The hydraulic oil station needs to add 46 # hydraulic oil. When filling, there is an oil gauge display, and the filling amount exceeds the scale of the oil gauge.

Fully automatic computer operation, easy to use, convenient and responsive.

The frame structure is welded with carbon steel plates, which has a long service life.

Low noise operation and short flattening time.

Good bearing capacity and easy operation.

Carefully selecting materials is the key to making good products.

On demand production, welcome to customize with pictures.

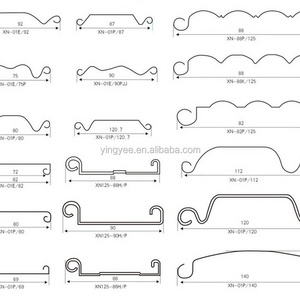

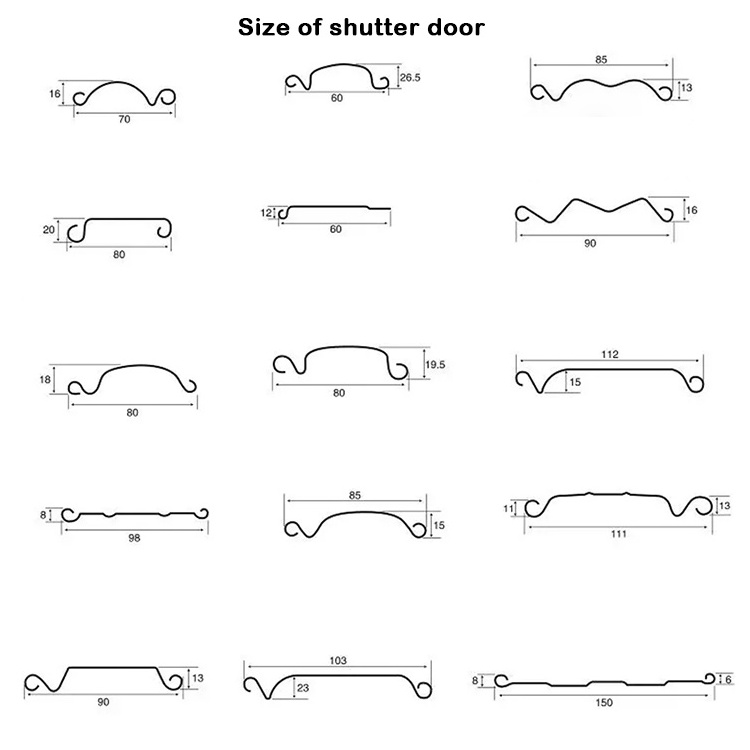

Glazed Type

Roll Forming Sheet

Corrugated Type Roll Forming Sheet

IBR Type Roll Forming Sheet

Roofing sheet has many different shapes,usually different countries have its own popular design ,we can customize the machine as customers’ demand.

Q1. How do I choose the right machine for me?

1. A machine doesn't just provide a few photos to prove what they can produce .

2. A machine should have a complete production and assembly system photos and videos. When choosing a company with a factory, it is necessary to ensure that the company has a complete after-sales service system.

2. A machine should have a complete production and assembly system photos and videos. When choosing a company with a factory, it is necessary to ensure that the company has a complete after-sales service system.

Q2. You did not display the product I need. Can you produce it?

Our engineers have studied at well-known European companies and have significant advantages in mechanical design, research and development, and manufacturing.

Q3. How long can the machine be built?

Generally speaking, the machine takes about 20 days to complete, if you need a machine urgently, we can make it urgently, because I have a large number of spare parts.

Q4. Why are your prices higher than others?

Because we insist that every factory should put quality first, we make the machines more automated, more reliable and accurate,and have a longer service life. The equipment can be used for nearly 20 years, and we provide lifetime after-sales service.

Q5. Do you have after-sales support?

Product quality is the ultimate, the biggest after-sales service is service, to be a service company that you have the strength to guarantee.

Q6. How to get a quotation?

1. Give me the dimension drawing and thickness, it is very important.

2. If you have requirements for production speed, power, voltage and brand, please explain in advance.

3. If you don't have your own outline drawing, we can recommend some models according to your local market standard.

Generally speaking, the machine takes about 20 days to complete, if you need a machine urgently, we can make it urgently, because I have a large number of spare parts.

Q4. Why are your prices higher than others?

Because we insist that every factory should put quality first, we make the machines more automated, more reliable and accurate,and have a longer service life. The equipment can be used for nearly 20 years, and we provide lifetime after-sales service.

Q5. Do you have after-sales support?

Product quality is the ultimate, the biggest after-sales service is service, to be a service company that you have the strength to guarantee.

Q6. How to get a quotation?

1. Give me the dimension drawing and thickness, it is very important.

2. If you have requirements for production speed, power, voltage and brand, please explain in advance.

3. If you don't have your own outline drawing, we can recommend some models according to your local market standard.

Hot Searches