1. Fully Machining Services:

Machining parts ,CNC Machining parts, CNC milling and turning parts , CNC milling parts, CNC lathe turning parts, grinding parts, stamping parts, casting and forging parts, assembly service.

2.Various Machining Materials:

stainless steel machining parts , alloy steel machining parts ,brass machining parts , bronze machining parts , copper machining parts , aluminum machining parts , plastic machining parts , or customer specified.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Customized

-

material:

-

ABS, PC, PP, PS,TPE,TPU

-

Working Process:

-

injection, extruding, blow molding,rotational molding, casting

-

Surface treatment:

-

powder coating, polishing, chrome plating

-

Equipments:

-

CNC, EDM, ArgieCharmilles, Milling Machine

-

Product name:

-

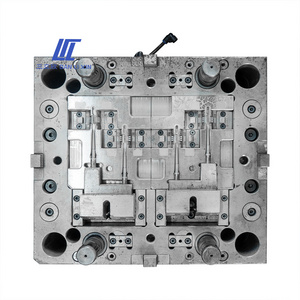

injection molding customized plastic parts

Quick Details

-

Processing Service:

-

Moulding

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

strong

-

Model Number:

-

Customized

-

material:

-

ABS, PC, PP, PS,TPE,TPU

-

Working Process:

-

injection, extruding, blow molding,rotational molding, casting

-

Surface treatment:

-

powder coating, polishing, chrome plating

-

Equipments:

-

CNC, EDM, ArgieCharmilles, Milling Machine

-

Product name:

-

injection molding customized plastic parts

Product Application

All kinds of cars, machinery, home appliance, electronic products, electric appliance, stationery, computers, power switches, miniature switches, architecture, commodity and A/V equipment, hardware and plastic molds, sports equipment and gifts, and more

|

Item

|

Description

|

|

Product Name

|

Plastic part

|

|

Working Process

|

injection, extruding, blow molding,rotational molding, casting,drawing, stamping

|

|

Material

|

ABS, PC, PP, PS, POM, PMMA

|

|

Mould Base Material:

|

LKM, FUTA, HASCO, DME, etc. or as per customer' s requirement.

|

|

Surface treatment

|

powder coating, polishing, chrome plating

|

|

Color

|

Red, blue, green, yellow

|

|

Packing

|

Inner-Plastic Bag; Outer -Standard Carton Box.

|

|

Usage

|

All kinds of cars, machinery, home appliance, electronic products, electric appliance, stationery, computers, power switches, miniature switches, architecture, commodity and A/V equipment, hardware and plastic molds, sports equipment and gifts, and more

|

|

Quality Control

|

Conducted by ISO/TS16949:2002 and ISO14001:2004 system.

|

|

Cavity Number:

|

Single cavity, Multi Cavity, based on customer' s requirement.

|

|

Applications

|

auto,motorcycle,industry,ariculture,mine,furniture,elevator,etc

|

|

Equipments:

|

CNC, EDM, ArgieCharmilles, Milling Machine, 3D CMM, Projector, HG, Injection Machine

|

|

File Format

|

Solidworks,Pro/Engineer,Auto CAD,PDF,JPG

|

|

Service

|

Warm and quick response service provided by the professional Export Sales Team with many years' experience in handling exports to the US, Europe, Japan and other countries and regions.

|

|

Inspection

|

IQC, IPQC,FQC,QA

|

Feature

(1)Material:ABS,PP,PC,PBT,PVC,PA6,PA66,TPEE,PC+ABS,etc.

(2)Injection parts' surface treatment:Color painting,Texture,Silk-printing, Anodize etc.

(3)ODM&OEM service are all welcomed

(4)Practicable Software:Pro/engineer,Solidworks,UG,Auto cad.

(5)Mold Making Time: 15-35 days

Pre-sale

Your inquiry will be replied by our well-trained & experienced staff within 24hours

Shipping

Small order: By express, DHL/UPS/Fedex, etc.

Big order: By sea or airWe will choose or advices the best convenience way for you

After-sale

If you get any question please feel free to email us, or ring us.

Machining Parts

Stamping Parts

Material:

The use of material involve many types,such as Stainless steel,Aluminum,Brass,Bronze.SGCC,SECC,SPCC,etc.If you have special request in material.Please let me know.Every material is ok to us.

Finish

:Zinc/Nickel/Chrome plating,Powder coating,Anodize,etc.It is of great importance to product's appearance and use.

Application

: Our products extensively are used in many fields of communication equipment,electric equipment,security equipment,industry control equipment,medical equipment and consumer filds.

Prduction

Product Inspection

Q1: How can I get the quotation?

A: Please send us 3D drawing or sample.

Q2: What format 3D drawing can you accept?

A: 3D drawing in X-T,stp,step format will be nice.

Q3: How soon can I get the quotation?

A: Within 24 hours after receiving your 3D drawing.

Q4: I have no 3D drawing, how should I start the project?

A: You can supply us a sample, our engineer will help to finish the 3D drawing design.

Q5: How will you control the quality?

A: We have quality control department, which will set up control plan before stating the project, all PPAP report will be provided along the whole process.

Q6: Have you ever exported?

A: Yes, our customers come from many countries, including North America, Russia,some european countries etc.