- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v/50hz/3phase

-

Dimension(L*W*H):

-

Depends on Capacity

-

Weight:

-

3400 KG

-

Process Type:

-

Flotation separation

-

Application range:

-

Copper, Lead-zinc

-

Capacity:

-

1-50 tph

-

Recovery rate:

-

90-95%

-

Feeding Size:

-

0-300 mm

-

Main Machine 1:

-

Jaw crusher, hammer crusher

-

Main Machine 2:

-

Ball mill, spiral classifier

-

Main Machine 3:

-

Flotation tank, mixing tank

-

Main Machine 4:

-

Vibrating Screen

-

Main Machine 5:

-

Magnetic Separator

Quick Details

-

Production Capacity:

-

High

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

HENGZHONG

-

Voltage:

-

380v/50hz/3phase

-

Dimension(L*W*H):

-

Depends on Capacity

-

Weight:

-

3400 KG

-

Process Type:

-

Flotation separation

-

Application range:

-

Copper, Lead-zinc

-

Capacity:

-

1-50 tph

-

Recovery rate:

-

90-95%

-

Feeding Size:

-

0-300 mm

-

Main Machine 1:

-

Jaw crusher, hammer crusher

-

Main Machine 2:

-

Ball mill, spiral classifier

-

Main Machine 3:

-

Flotation tank, mixing tank

-

Main Machine 4:

-

Vibrating Screen

-

Main Machine 5:

-

Magnetic Separator

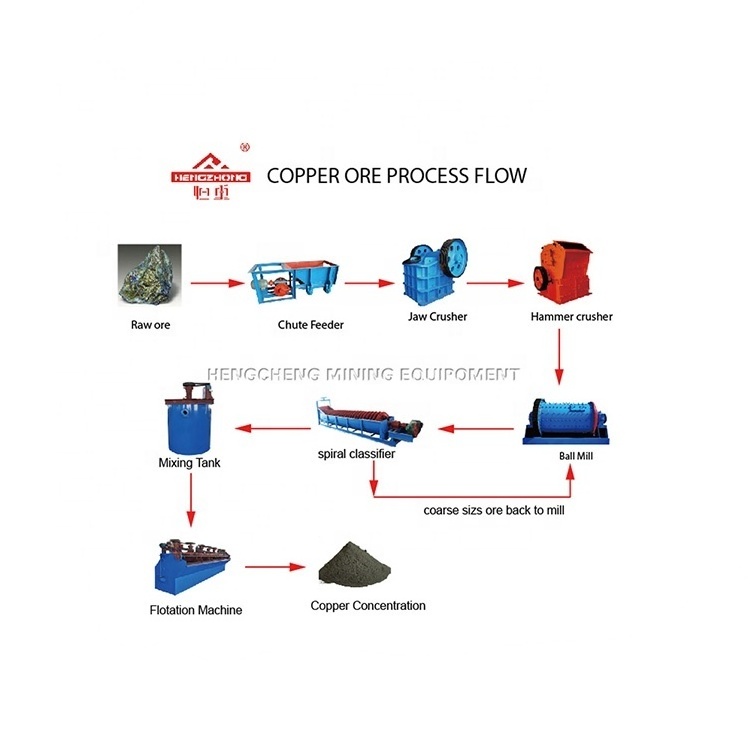

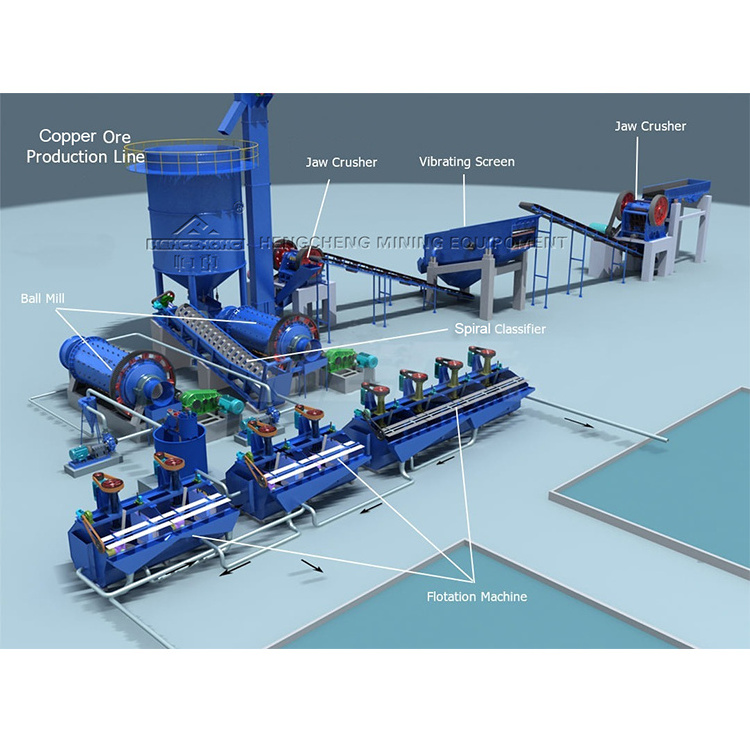

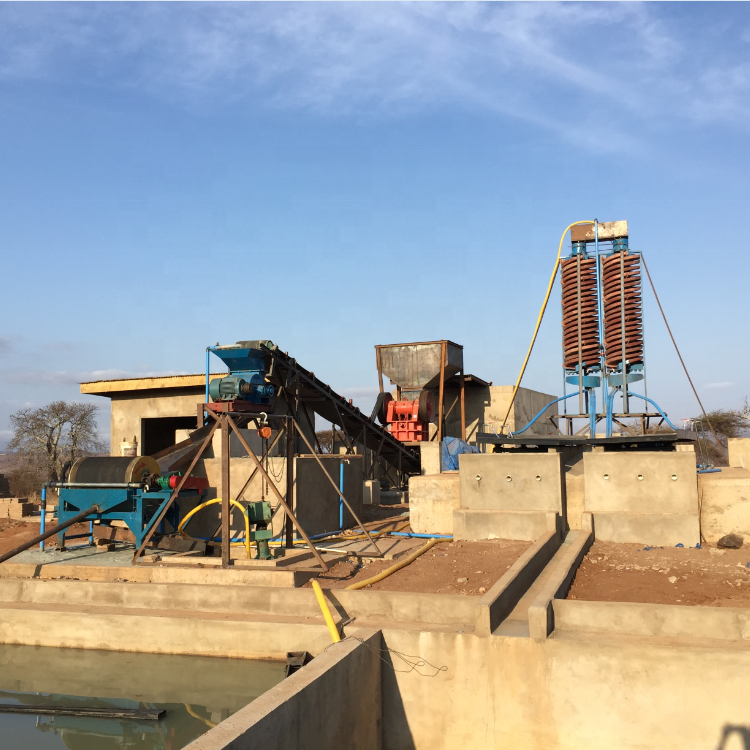

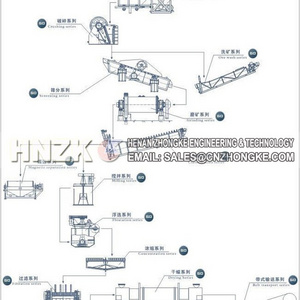

Copper Ore Beneficiation Plant /flotation machine /copper processing plant for sale

1. Jaw crusher

Gold mining equipment jaw crusher is preferable to be selected as primary machine for various materials with compressive strength up to 320MPa in mining industry.

2. Hammer Crusher

Gold mining equipment hammer crusher is widely used for medium and fine crushing in mineral processing plant , cement, glass and refractory factories. It can be used in both dry and wet crushing.

3.Ball Mill

Gold mining equipment ball mill is a key equipment to grind the crushed materials, and it is widely used in powder-making production line including cement, silicate, new-type building material, refractory material, fertilizer, ore dressing of ferrous metal and non-ferrous metal, glass ceramics, etc. And the ball mill can grind various ores and other materials with dry type and wet type. There are two kinds of ball mill, grate type and overfall type due to different ways of discharging material.

4.Spiral Classifier

Gold mining equipment spiral classifier mainly used mineral classification after grinding mineral, widely used with ball mill to form a closed-circuit to distribute sands, or used for grading ore sand and fine mud in gravity separation, grading ore sand according to particle size, deslime and dehydration.

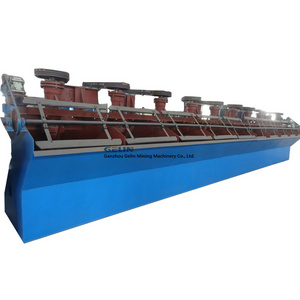

5.SF Flotation machine

Flotation machine is a process for separating minerals from gangue by taking advantage of differences in their hydrophobicity . Hydrophobicity differences between valuable minerals and waste gangue are increased through the use of surfactants and wetting agents. The selective separation of the minerals makes processing complex (that is, mixed) ores economically feasible. The flotation process is used for the separation of a large range of sulfides , carbonates and oxides prior to further refinement. Phosphates and coal are also upgraded (purified) by flotation technology.

Flotation is undoubtedly the most important and versatile mineral processing technique and its application is being expanded to treat greater tonnages and to cover new areas. In flotation cell concentration, the mineral is usually transferred to the froth, or float fraction, leaving the gangue in the pulp or tailing.

Technical data:

|

Volume (m3) |

Impeller Diameter(mm) |

Capacity (m3/min) |

Impeller Speed(r/min) |

Motor Power(KW) |

Dimensions (L*W*H) (mm) |

|

|

SF-0.37 |

0.37 |

300 |

0.2-0.4 |

352 |

0.55 |

700*700*750 |

|

SF-0.7 |

0.7 |

350 |

0.3-0.9 |

400 |

1.1 |

920*820*950 |

|

SF-1.2 |

1.2 |

450 |

0.6-1.2 |

312 |

1.5 |

1100*1100*1100 |

|

SF-2.8 |

2.8 |

550 |

1.5-3.5 |

268 |

1.5 |

1700*1600*1150 |

|

SF-4 |

4 |

650 |

0.5-4 |

238 |

1.5 |

1850*2050*1200 |

Export standard container 20GP or 40GP,40HQ,FR container,In bulk,the spare parts in wooden case .