- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm, 390*190*190mm,240*115*90mm,240*115*50mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

BRK

-

Voltage:

-

110-440V

-

Dimension(L*W*H):

-

3500*1800*2300mm

-

Weight (KG):

-

3200 kg

-

Raw material:

-

CONCRETE

-

Block Type:

-

Hollow Solid Paver Block Curbstone

-

Advantage:

-

Automatic Hydraulic Block Production Line

-

Pallet size:

-

850*550*20MM

-

Model:

-

QT4-25

-

Molding cycle:

-

20-25s

-

Machine Type:

-

block making machine in Somali

-

Power:

-

17.9KW

-

Vibration frequency:

-

4200r/min

-

Pressure:

-

16-22mpa

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine

-

Brick Raw Material:

-

CONCRETE

-

Production Capacity (Pieces/8 hours):

-

4500-13000 pcs/8hours

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm, 390*190*190mm,240*115*90mm,240*115*50mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

BRK

-

Voltage:

-

110-440V

-

Dimension(L*W*H):

-

3500*1800*2300mm

-

Weight (KG):

-

3200 kg

-

Raw material:

-

CONCRETE

-

Block Type:

-

Hollow Solid Paver Block Curbstone

-

Advantage:

-

Automatic Hydraulic Block Production Line

-

Pallet size:

-

850*550*20MM

-

Model:

-

QT4-25

-

Molding cycle:

-

20-25s

-

Machine Type:

-

block making machine in Somali

-

Power:

-

17.9KW

-

Vibration frequency:

-

4200r/min

-

Pressure:

-

16-22mpa

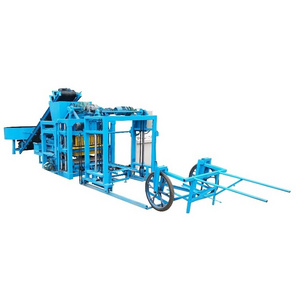

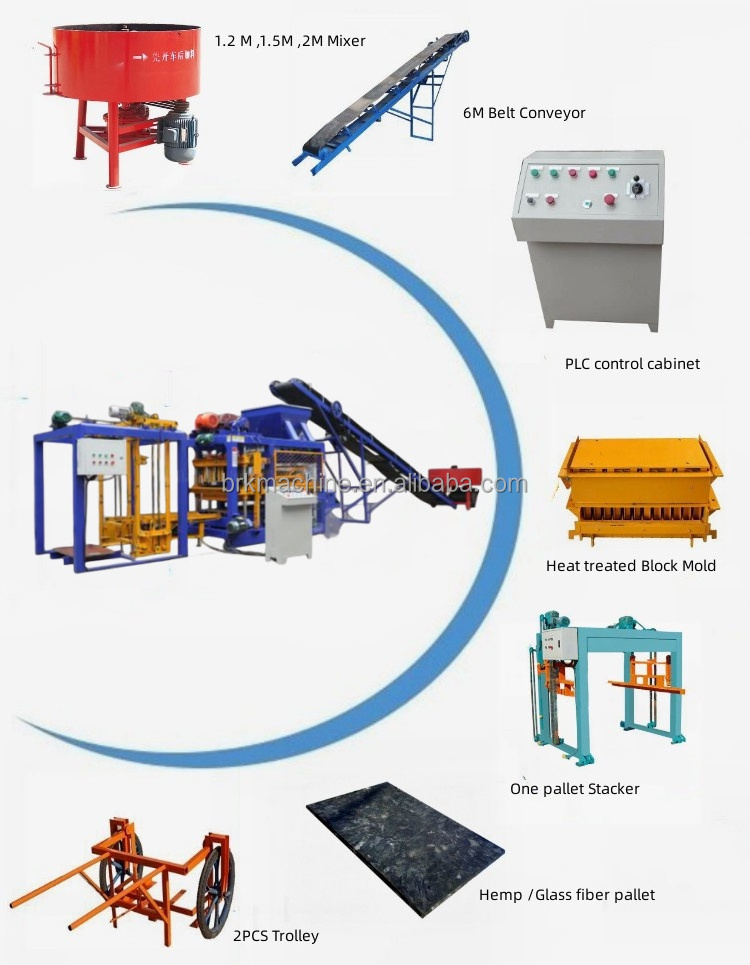

QT4-25 Machine making brick prices of block moulding machine in Ghana

Description:

QT4-25 block machine making automatic is one of our sell best machine model, it is automatic block machine, suitable for making all types of hollow blocks, solid block, pavers, curbstones and so on. it is designed for medium scale block project. It's automatic materials feeding, pallet feeding, distributing, brick forming, and finished block pushing out . This model block machine is very economical, popular in developing countries.

QT4-25 block machine making automatic is one of our newly designed block making machines. With less power, it achieves super strong vibration. It adopts full automatic spiral material laying method, so the material in the mould is well-distributed. With simple operation and high productivity, when producing hollow blocks, it has an advantage over the large hydraulic block machines.

Main technical parameters:

| Model | QT4-25 ,QTJ4-25 |

| Rated pressure | 21Mpa |

| Dimension | 3500*1800*2300mm |

| Forming Cycle | 25-30s |

| Vibration form | Platform vibration |

| Weight | 3200kg |

| Motors Power | 17.9KW |

| Vibrating Frequency | 2800-4500 rolls/minute |

| Pallet size | 850*550mm |

| Raw Materials | Crushed stone, sand, cement, dust and coal fly ash, cinder, slag, gangue, gravel, perlite, and other industrial wastes. |

| Block Types | Concrete blocks, solid/hollow/cellular masonry products, paving stones with or without face mix, garden and landscaping products, slabs, edgers, kerbstones, grass blocks, slope blocks, interlocking blocks, etc. |

| Applied Fields | Widely used in buildings, road pavings, squares, gardens, landscaping, city constructions, etc. |

Production capacity:

Main Features:

Fully automatic,hydraulic,Mitsubishi PLC control

Raw materials are generally cement, sand, gravels, crushed stone powder, slags, fly ash, ect, depending on customers' choice.

A. 8-10% cement, 30-40% sand, 50-60% crushed stone

B. 8-10% cement, 30% flyash, 60% sand or stone powder The diameter of sand and stones need to be less than 15mm, if produce paver interlocking brick, need color iron.

QT4-25 Machine making brick prices of block moulding machine in Ghana

Customer Site:

Our services:

Pre-sale service

1.Professional advice on raw material and site selection.

2.Seletion of the most suitable machine.

3.24 hours online service.

4.Welcome to visit our factory at any time .

On sale service

1.Update the production scheduling in time

2.Quality supervision

3.Product acceptance and testing

4.Shipping on time

After sale service

1.Free online guidance and tutorials

2.Professional engineer training service

3.One year quality guarantee period.

4.Regular return visits to customer usage

Packing and deliver :

Packing shall be wrapped with plastic film or according to the customer's require.

1. The whole brick machine production line is mainly full container shipping,

2. Wrap the whole brick machine with plastic film before shipment to prevent water or moisture,

3. Then load the brick machine into the container with a forklift,

4. During loading, tighten the machine with the reinforcing ring in the container to avoid damage caused by transportation bumps on the brick machine.