- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

DAWSON

-

Year:

-

New

-

Voltage:

-

440V/415V/380V/220V

-

Dimension(L*W*H):

-

4.2*2.2*2.7

-

Hollow part volume:

-

5L

-

Screw L/D Ratio:

-

24

-

Screw diameter (mm):

-

75 mm

-

Screw Heating Power(kW):

-

7 kW

-

Extruder Motor Power(kW):

-

22 kW

-

Mold Platen Size(Width)(mm):

-

380 mm

-

Mold Platen Size(Height)(mm):

-

420 mm

-

Air Pressure(MPa):

-

0.6 MPa

-

Air Comsumption(m³/min):

-

0.8 m³/min

-

Die Head Heating Power(kW):

-

3 kW

-

Accumulator Capacity(L):

-

0 L

-

Power (kW):

-

36

-

Weight (T):

-

7.5

-

Blow Molding Type:

-

Extrusion Blow Molding Machine

-

Maximum Application Size:

-

5L

-

Cooling water pressure:

-

0.3 MPA

-

Water Consumption:

-

80 L/Min

-

Mould Lifespan:

-

> 1,000,000 Cycles

-

Mold Material:

-

P20, 2316, S136H, Aluminum with beryllium copper.

-

Language settings:

-

Chinese and English operation panel

-

Instructions provided:

-

Instructions in Chinese and English

-

Labor demand:

-

1~2 operetor

-

Samples provided:

-

If required

Quick Details

-

Clamping Force (kN):

-

80

-

Output (kg/h):

-

100 kg/h

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

DAWSON

-

Year:

-

New

-

Voltage:

-

440V/415V/380V/220V

-

Dimension(L*W*H):

-

4.2*2.2*2.7

-

Hollow part volume:

-

5L

-

Screw L/D Ratio:

-

24

-

Screw diameter (mm):

-

75 mm

-

Screw Heating Power(kW):

-

7 kW

-

Extruder Motor Power(kW):

-

22 kW

-

Mold Platen Size(Width)(mm):

-

380 mm

-

Mold Platen Size(Height)(mm):

-

420 mm

-

Air Pressure(MPa):

-

0.6 MPa

-

Air Comsumption(m³/min):

-

0.8 m³/min

-

Die Head Heating Power(kW):

-

3 kW

-

Accumulator Capacity(L):

-

0 L

-

Power (kW):

-

36

-

Weight (T):

-

7.5

-

Blow Molding Type:

-

Extrusion Blow Molding Machine

-

Maximum Application Size:

-

5L

-

Cooling water pressure:

-

0.3 MPA

-

Water Consumption:

-

80 L/Min

-

Mould Lifespan:

-

> 1,000,000 Cycles

-

Mold Material:

-

P20, 2316, S136H, Aluminum with beryllium copper.

-

Language settings:

-

Chinese and English operation panel

-

Instructions provided:

-

Instructions in Chinese and English

-

Labor demand:

-

1~2 operetor

-

Samples provided:

-

If required

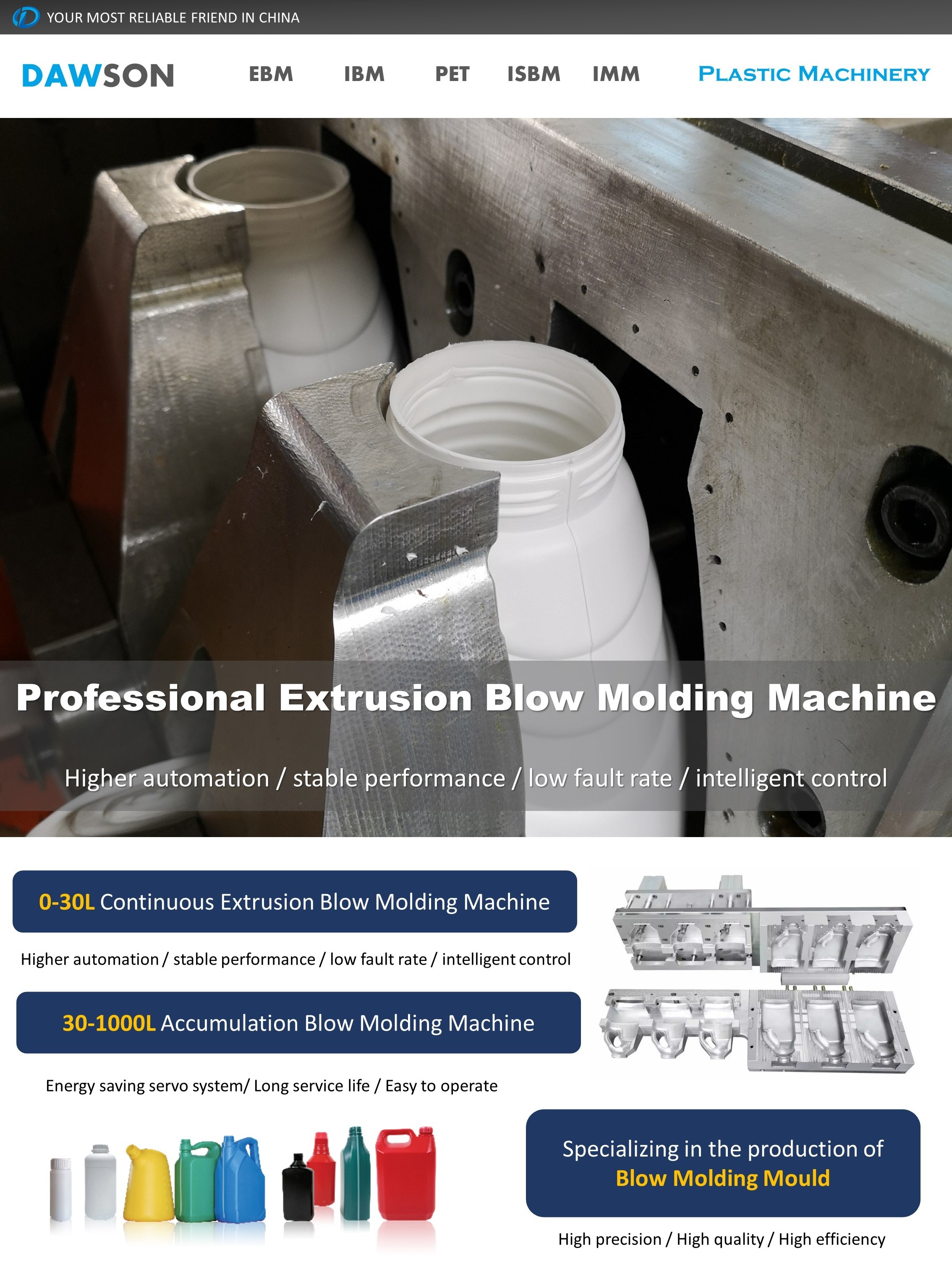

Products Description

DAWSON MACHINERY & MOULD GROUP

1 Gallon Extrusion Blow Molding

Machine ABLB75

suitable for making plastic bottle, jars, small containers, jerrycans, gallon from 50ml to 5L,

The whole blow molding machine is equipped

with bilingual operation panel

and automatic configuration from world famous brands to realize the advantages of simple operation

and high automation.

|

Machine Model

|

|

Max. Bottle size

|

Production forecast

|

|

|

ABLB65

|

Double Station

Double

Head

|

1L

|

450~480 BPH

|

|

|

|

Double Station

Single

Head

|

5L

|

280~320 BPH

|

|

Technical Parameters

|

Name

|

Units

|

ABLB65II

|

ABLB75II

|

|

Max.product volume

|

L

|

3.5

|

8

|

|

Screw diameter

|

MM

|

65

|

75

|

|

Screw drive power

|

KW

|

18.5

|

22

|

|

Output of HDPE

|

KG/H

|

75

|

100

|

|

Oil pump drive power

|

KW

|

7.5

|

7.5

|

|

Clamping force

|

KN

|

65

|

80

|

|

Max.size of mold

|

MM

|

320×350

|

400×430

|

|

Template size

|

MM

|

290×320

|

380×420

|

|

Mold stroke

|

MM

|

150-500

|

170-520

|

|

Max.die diameter

|

MM

|

170

|

170

|

|

Size of machine

|

L×W×H

|

3.9×2.2×2.6

|

4.2×2.2×2.7

|

|

Weight of machine

|

TON

|

6.5

|

7.5

|

Details Images

Professional Workshop

Our professional blow molding machine workshop...

High Quality Mould

High Quality Blow Molding mould

In the process of plastic blow molding, the mold is a very important part. A good blow mould can make the product production more smoothly, and a good blowing mold can also make the finished product more flexible and beautiful.

We have our own mold production workshop, using high configuration equipment and mold engineers with 16 years of technical experience to customize blow molding mold for you.

- We use the best stainless steel S136H or Aluminium alloy 7075# as mould main material- Necking plate use JAPAN DC53 Heat

treatment to HRC62

- Double neck design available to change in future as a spare part necking

- All mould can be made auto-deflashing or manual deflashing as per customer requests

- Perfect mould cooling design to ensure the best moulding preformace

- Available to provide 2D & 3D product drawing for customers

- Available to send samples to customer for approval the product quality

- We had already made moulds for TOTAL,SHELL,GULF,BMW,YAMAHA,MOBIL,TOYOTA,MENGNIU, HYUNDAI,MENTHOLATUM,UNILEVER,LEE KUM KEE...

In the process of plastic blow molding, the mold is a very important part. A good blow mould can make the product production more smoothly, and a good blowing mold can also make the finished product more flexible and beautiful.

We have our own mold production workshop, using high configuration equipment and mold engineers with 16 years of technical experience to customize blow molding mold for you.

- We use the best stainless steel S136H or Aluminium alloy 7075# as mould main material- Necking plate use JAPAN DC53 Heat

treatment to HRC62

- Double neck design available to change in future as a spare part necking

- All mould can be made auto-deflashing or manual deflashing as per customer requests

- Perfect mould cooling design to ensure the best moulding preformace

- Available to provide 2D & 3D product drawing for customers

- Available to send samples to customer for approval the product quality

- We had already made moulds for TOTAL,SHELL,GULF,BMW,YAMAHA,MOBIL,TOYOTA,MENGNIU, HYUNDAI,MENTHOLATUM,UNILEVER,LEE KUM KEE...

Hot Searches