The control panel on the filling machine is the core of the machine, the function is clear, the operation is simple, as long as adjust the corresponding button, the internal program will control the machine to run smoothly

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

99.9%

-

Packaging Type:

-

Other

-

Voltage:

-

220V 50-60HZ

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

powerrig

-

Dimension(L*W*H):

-

1950*800*1850mm

-

Weight:

-

850 KG

-

Machinery Test Report:

-

Available

-

Product name:

-

Aluminum

-

After-sales Service Provided:

-

Online Technical Support

-

Function:

-

Automatic Filler

-

Name:

-

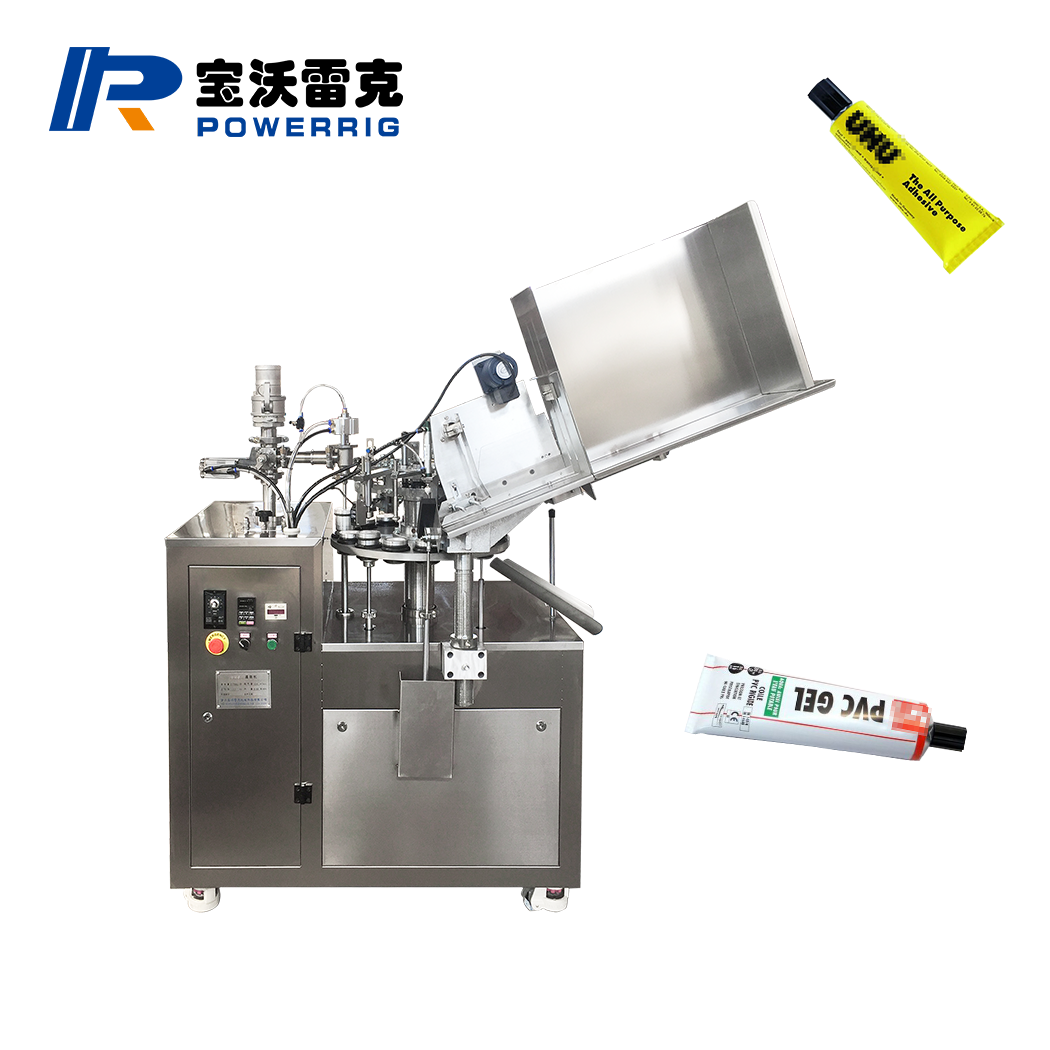

3 In1washing Filling Capping Machine

-

Usage:

-

Chemcial

-

Keywords:

-

Fillng Machine

-

Advantage:

-

Easy Clean

-

Model:

-

Water Filling Equipment

-

Control:

-

Control System

-

Machine name:

-

Autoamtic Tube Filling

Quick Details

-

Machinery Capacity:

-

4000BPH, 400BPH, 500BPH, 2000BPH, 1000BPH, 100BPH, 200BPH, Other

-

Packaging Material:

-

Metal, Other

-

Filling Material:

-

Other

-

Filling Accuracy:

-

99.9%

-

Packaging Type:

-

Other

-

Voltage:

-

220V 50-60HZ

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

powerrig

-

Dimension(L*W*H):

-

1950*800*1850mm

-

Weight:

-

850 KG

-

Machinery Test Report:

-

Available

-

Product name:

-

Aluminum

-

After-sales Service Provided:

-

Online Technical Support

-

Function:

-

Automatic Filler

-

Name:

-

3 In1washing Filling Capping Machine

-

Usage:

-

Chemcial

-

Keywords:

-

Fillng Machine

-

Advantage:

-

Easy Clean

-

Model:

-

Water Filling Equipment

-

Control:

-

Control System

-

Machine name:

-

Autoamtic Tube Filling

Product Introduction

|

Weight

|

450Kg

|

|

Power

|

220V/50Hz

|

|

Filling Quantity

|

1-5g/5-25g/20-75g/75-250g

|

|

Suitable Filling Material

|

Aluminum and metal tube

|

|

Date Printed

|

1-2 rows(numbers & letters)

|

|

Dimension

|

1500*700*1800mm

|

|

Motor

|

1.5Kw

|

|

Capacity

|

25-35 tubes/min

|

|

Maximum Tube Dia.

|

60 mm

|

|

Additional Function

|

Air pressured tank Diving filling function

|

The control panel

Automatic tube feeding system

Its main function is to make the pipes in order on the top, into the filling machine, the whole process can be controlled by the touch screen, the internal program will automatically complete the tube work. Effectively save labor cost

The main platform

Main workflow: automatically goes on the tube. When the tube comes, the sensor automatically identifies it, sends a signal to the filling station, and starts the filling.After the filling, the tail of the pipe is flattened, folded, folded forward and back, date printed, and finally the pipe is topped out

The cylinder

The internal system controls the movement of the cylinder so that the material can be smoothly filled into the container

Related Product

Company introduction

Hot Searches