- Product Details

- {{item.text}}

Quick Details

-

Features:

-

high powerful/Easy to Operate

-

Production Capacity:

-

High performance

-

Warranty:

-

1year

-

Dimension(L*W*H):

-

1327mm(Arm length)

-

Power:

-

180W

-

Voltage:

-

200-240V AC,50-60Hz(Power Input)

-

Weight (KG):

-

41

-

Marketing Type:

-

New Product

-

Product Name:

-

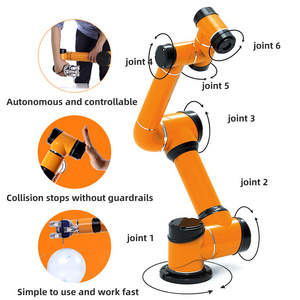

JAKA Cobot Robot

-

Robot Brand:

-

JAKA

-

Arm length:

-

1327mm

-

Repeatability:

-

0.03mm

-

Axis:

-

6

-

Payload:

-

12kg

-

Installation Method:

-

floor/Ceiling/Wall

-

IP level:

-

IP44

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JAKA

-

Application:

-

Metal Processing,Medical,Chemical,Semiconductor,

-

Features:

-

high powerful/Easy to Operate

-

Production Capacity:

-

High performance

-

Warranty:

-

1year

-

Dimension(L*W*H):

-

1327mm(Arm length)

-

Power:

-

180W

-

Voltage:

-

200-240V AC,50-60Hz(Power Input)

-

Weight (KG):

-

41

-

Marketing Type:

-

New Product

-

Product Name:

-

JAKA Cobot Robot

-

Robot Brand:

-

JAKA

-

Arm length:

-

1327mm

-

Repeatability:

-

0.03mm

-

Axis:

-

6

-

Payload:

-

12kg

-

Installation Method:

-

floor/Ceiling/Wall

-

IP level:

-

IP44

Product Description

|

Products Name

|

JAKA Cobot Robot

|

|

|

Technical data

|

|

|

|

Robot Arm Length

|

1327mm

|

|

|

Payload

|

12KG

|

|

|

Repeativity

|

0.03mm

|

|

|

Axis

|

6

|

|

|

Installation Method

|

floor,ceilimg,wall

|

|

|

Weight

|

41kg

|

|

|

Motion Range

|

|

|

|

A1

|

+_170°

|

|

|

A2

|

-185°/65°

|

|

|

A3

|

-137°/163°

|

|

|

A4

|

+—185°

|

|

|

A5

|

+—120°

|

|

|

A6

|

+—350°

|

|

|

Speed with rated payload

|

|

|

|

A1

|

220°/s

|

|

|

A2

|

210°/s

|

|

|

A3

|

270°/s

|

|

|

A4

|

381°/s

|

|

|

A5

|

311°/s

|

|

|

A6

|

492°/s

|

|

|

Operating conditions

|

|

|

|

IP Level

|

IP44

|

|

|

Temperature

|

5°C to 45°C(278K to 318K)

|

|

|

Controller

|

KR C4 compact

|

|

JAKA Cobot Robot

JAKA Cobot Robot has been constantly exploring the breadth and depth for serving human by its self-developed leading collaborative

robot technologies. The payload of the robots vary from 3kg to 18kg which can meet the requirements of various customers.Moreover,

Han’s Robot has developed products from the first generation 6-axis collaborative robots Elfin robot to the second-generation

Elfin-P robot with higher performance, and has released 7-axis intelligent collaborative robots MAiRA in March 2021.G series

6-axis collaborative robots can be used in automated integrated production lines, assembly, picking, welding, grinding,painting

and other fields, and have been successfully exported to more than 100 countries and regions including Europe, America,Japan and

South Korea. The G series collaborative robot adopts a unique dualjoint module design. One motion module contains two joints,

which constitute a unique kinematic structure, which is not only different from most collaborative robots in the market in

appearance, but also can achieve higher flexibility during work.

robot technologies. The payload of the robots vary from 3kg to 18kg which can meet the requirements of various customers.Moreover,

Han’s Robot has developed products from the first generation 6-axis collaborative robots Elfin robot to the second-generation

Elfin-P robot with higher performance, and has released 7-axis intelligent collaborative robots MAiRA in March 2021.G series

6-axis collaborative robots can be used in automated integrated production lines, assembly, picking, welding, grinding,painting

and other fields, and have been successfully exported to more than 100 countries and regions including Europe, America,Japan and

South Korea. The G series collaborative robot adopts a unique dualjoint module design. One motion module contains two joints,

which constitute a unique kinematic structure, which is not only different from most collaborative robots in the market in

appearance, but also can achieve higher flexibility during work.

ER Series Flexible Cooperative Robot

SR Series Collaborative Robot

CR Series Flexible Cooperative Robot

Automatic Rotary Loading/Unloading Bin / Machine Tool Loading/Unloading Bin

Automatic Feed Pallet Bin / Palletizing Cooperative Bin / Automatic Loading And Unloading

Industrial Robot Bin / Automatic Circulation Chain Bin

Single axis horizontal servo positioner

Single axis main tail box type servo positioner

Spindle box type single axis servo positioner

Vertical flipping three-axis servo positioner

Horizontal rotary three-axis servo positioner

Transfer robot

Welding robot

Stamping machine

Cooperative Robot

Conveyor line

Positioner

Silo

Ground track

Specification

|

|

SR3

|

|

SR4

|

|

||||

|

Specification

|

|

|

|

|

||||

|

Load

|

3kg

|

|

4kg

|

|

||||

|

Working radius

|

580mm

|

|

800mm

|

|

||||

|

Dead weight

|

Approx. 14kg

|

|

Approx. 17kg

|

|

||||

|

Degree of Freedom

|

6 rotary joints

|

|

6 rotary joints

|

|

||||

|

MTBF

|

> 50000h

|

|

> 50000h

|

|

||||

|

Power supply

|

AC-220V/DC 48V

|

|

AC-220V/DC 48V

|

|

||||

|

Programming

|

Drag teaching and graphical interface

|

|

Drag teaching and graphical interface

|

|

||||

|

Performance

|

|

|

|

|

||||

|

POWER

|

Average

|

Peak

|

Averagr

|

Peak

|

||||

|

CONSUMPTION

|

180w

|

400w

|

180w

|

400w

|

||||

|

Safety

|

More than 20 adjustable safety functions such as collision detection, virtual wall and collaboration mode

|

|

|

|

||||

|

Certification

|

Comply with ISO-13849-1, Cat. 3, PL d. ISO-10218-1. EU CE Certification Standard

|

|

|

|

||||

|

Force sensing, tool flange

|

Force, x-y-Z

|

Moment of force, x-y-z

|

Force, x-y-Z

|

Moment of force, x-y-z

|

||||

|

Resolution ratio of force measurement

|

0.1N

|

0.02Nm

|

0.1N

|

0.02Nm

|

||||

|

Range of operating temperature

|

0~45 ℃

|

|

0~45 ℃

|

|

||||

|

Humidity

|

20-80%RH (non-condensing)

|

|

20-80%RH (non-condensing)

|

|

||||

|

Relative accuracy of force control

|

0.5N

|

0.1Nm

|

0.5N

|

0.1Nm

|

||||

|

Motion

|

|

|

|

|

||||

|

Repeatability

|

±0.03 mm

|

|

±0.03 mm

|

|

||||

|

Motor joint

|

Scope of work

|

Maximum speed

|

Scope of work

|

Maximum speed

|

||||

|

Axis1

|

±175°

|

180°/s

|

±175°

|

180°/s

|

||||

|

Axis2

|

-135°~±130°

|

180°/s

|

-135°~±135°

|

180°/s

|

||||

|

Axis3

|

-175°~±135°

|

180°/s

|

-170°~±140°

|

180°/s

|

||||

|

Axis4

|

±175°

|

225°/s

|

±175°

|

225°/s

|

||||

|

Axis5

|

±175°

|

225°/s

|

±175°

|

225°/s

|

||||

|

Axis6

|

±175°

|

225°/s

|

±175°

|

225°/s

|

||||

|

Maximum speed at tool end

|

≤1.5m/s

|

|

≤2m/s

|

|

||||

|

Features

|

|

|

|

|

||||

|

IP Protection grade

|

IP54

|

|

|

|

||||

|

Robot mounting

|

Installation at any angle

|

|

|

|

||||

|

Tool I/O Port

|

2DO,2DI,2Al

|

|

|

|

||||

|

Tool communication interface

|

1-way 100-megabit Ethernet connection base RJ45 network interface

|

|

|

|

||||

|

Tool I/O Power Supply

|

(1)24V/12V,1A (2)5V, 2A

|

|

|

|

||||

|

Base Universal I/O Port

|

4DO, 4DI

|

|

|

|

||||

|

Base communication interface

|

2-Way Ethernet/lp 1000Mb

|

|

|

|

||||

|

Base output power supply

|

24V, 2A

|

|

|

|

||||

Product Application

The x Mate flexible collaborative robot has been widely used in the fields of automobile and parts, 3C and semiconductors, metal and plastics processing, scientific research education, commercial service, medical care and so on, to improve the output and quality of various industries, realize flexible production and improve staff safety.

|

|

ER3

|

|

ER7

|

|

ER3 Pro

|

|

ER7 Pro

|

|

||||||||

|

Specification

|

|

|

|

|

|

|

|

|

||||||||

|

Load

|

3kg

|

|

7kg

|

|

3kg

|

|

7kg

|

|

||||||||

|

Working radius

|

760mm

|

|

850mm

|

|

760mm

|

|

850mm

|

|

||||||||

|

Dead weight

|

Approx. 21kg

|

|

Approx. 27kg

|

|

Approx. 22kg

|

|

Approx. 29kg

|

|

||||||||

|

Degree of Freedom

|

6 rotary joints

|

|

6 rotary joints

|

|

7 rotary joints

|

|

7 rotary joints

|

|

||||||||

|

MTBF

|

>35000h

|

|

>35000h

|

|

>35000h

|

|

>35000h

|

|

||||||||

|

Power supply

|

DC 48V

|

|

DC 48V

|

|

DC 48V

|

|

DC 48V

|

|

||||||||

|

Programming

|

Drag teaching and graphical interface

|

|

Drag teaching and graphical interface

|

|

Drag teaching and graphical interface

|

|

Drag teaching and graphical interface

|

|

||||||||

|

Performance

|

|

|

|

|

|

|

|

|

||||||||

|

POWER

|

Average

|

Peak value

|

Average

|

Peak value

|

Average

|

Peak value

|

Average

|

Peak

|

||||||||

|

CONSUMPTION

|

200w

|

400w

|

500w

|

900w

|

300w

|

500w

|

600w

|

1000w

|

||||||||

|

Safety

|

> 22 Adjustable Safety Functions

|

|

> 22 Adjustable Safety Functions

|

|

> 22 Adjustable Safety Functions

|

|

> 22 Adjustable Safety Functions

|

|

||||||||

|

Certification

|

Comply with “EN ISO 13849-1, Cat. 3, PL d, EU CE Certification” standard

|

|

Comply with “EN ISO 13849-1, Cat. 3, PL d, EU CE Certification” standard

|

|

Comply with “EN ISO 13849-1, Cat. 3, PL d, EU CE Certification” standard

|

|

Comply with “EN ISO 13849-1, Cat. 3, PL d, EU CE Certification” standard

|

|

||||||||

|

Force sensing, tool flange

|

force, X-y-Z

|

Moment of force, X-y-Z

|

Force, x-y-Z

|

Moment of force, X-y-Z

|

Force, x-y-Z

|

Moment of force, X-y-Z

|

Force, x-y-Z

|

Moment of force, x-y-z

|

||||||||

|

Resolution ratio of force measurement

|

0.1N

|

0.02Nm

|

0.1N

|

0.02Nm

|

0.1N

|

0.02Nm

|

0.1N

|

0.02Nm

|

||||||||

|

Relative accuracy of force control

|

0.5N

|

0.1Nm

|

0.5N

|

0.1Nm

|

0.5N

|

0.1Nm

|

0.5N

|

0.1Nm

|

||||||||

|

Adjustable range of Cartesian stiffness

|

0~3000N/m,0~300Nm/rad

|

|

0~3000N/m,0~300Nm/rad

|

|

0~3000N/m,0~300Nm/rad

|

|

0~3000N/m,0~300Nm/rad

|

|

||||||||

|

Range of operating temperature

|

0~40° ℃

|

|

0~40° ℃

|

|

0~40° ℃

|

|

0~40 ℃

|

|

||||||||

|

Humidity

|

20-80%RH (non-condensing)

|

|

20-80%RH (non-condensing)

|

|

20-80%RH (non-condensing)

|

|

20-80%RH (non-condensing)

|

|

||||||||

|

180°/s

|

|

|

|

|

|

|

|

|

||||||||

|

180°/s

|

±0.03 mm

|

|

±0.03 mm

|

|

±0.03 mm

|

|

±0.03 mm

|

|

||||||||

|

180°/s

|

Scope of work

|

Maximum speed

|

Scope of work

|

Maximum speed

|

Scope of work

|

Maximum speed

|

Scope of work

|

Maximum speed

|

||||||||

|

180°/s

|

±170°

|

180°/s

|

±170°

|

|

±170°

|

180°/s

|

±170°

|

110°/s

|

||||||||

|

Axis 2

|

±120°

|

180°/s

|

±120°

|

|

±120°

|

180°/s

|

±120°

|

110°/s

|

||||||||

|

Axis 3

|

±120°

|

180°/s

|

±120°

|

180°/s

|

±170°

|

180°/s

|

±170°

|

180°/s

|

||||||||

|

Axis 4

|

±170°

|

180°/s

|

±170°

|

180°/s

|

±120°

|

180°/s

|

±120°

|

180°/s

|

||||||||

|

Axis 5

|

±120°

|

180°/s

|

±120°

|

180°/s

|

±170°

|

180°/s

|

±170°

|

180°/s

|

||||||||

|

Axis 6

|

±360°

|

180°/s

|

±360°

|

180°/s

|

±120°

|

180°/s

|

±120°

|

180°/s

|

||||||||

|

Axis 7

|

------

|

------

|

------

|

------

|

±360°

|

180°/s

|

±360°

|

180°/s

|

||||||||

|

Maximum speed at tool end

|

≤3m/s

|

|

≤2.5m/s

|

|

≤3m/s

|

|

≤2.5m/s

|

|

||||||||

|

Features

|

|

|

|

|

|

|

|

|

||||||||

|

IP Protection grade

|

IP54

|

|

IP54

|

|

IP54

|

|

IP54

|

|

||||||||

|

ISO Clean Room Class

|

5

|

|

6

|

|

5

|

|

6

|

|

||||||||

|

Noise

|

≤70dB(A)

|

|

≤70dB(A)

|

|

≤70dB(A)

|

|

≤70dB(A)

|

|

||||||||

|

Robot mounting

|

Formal-mounted, inverted-mounted, side-mounted

|

|

Formal-mounted, inverted-mounted, side-mounted

|

|

Formal-mounted, inverted-mounted, side-mounted

|

|

Formal-mounted, inverted-mounted, side-mounted

|

|

||||||||

|

General-Purpose I/O Port

|

Digital Input4

|

|

Digital Input 4

|

|

Digital Input 4

|

|

Digital Input 4

|

|

||||||||

|

|

Digital Output4

|

|

Digital Output 4

|

|

Digital Output4

|

|

Digital Output 4

|

|

||||||||

|

Security I/O Port

|

External emergency stop 2

|

|

External emergency stop2

|

|

External emergency stop 2

|

|

External emergency stop2

|

|

||||||||

|

|

External safety door2

|

|

External safety door 2

|

|

External safety door 2

|

|

External safety door 2

|

|

||||||||

|

Tool Connector Type

|

M8

|

|

M8

|

|

M8

|

|

M8

|

|

||||||||

|

Tool I/O Power Supply Supply

|

24V/1A

|

|

24V/1A

|

|

24V/1A

|

|

24V/1A

|

|

||||||||

Industry Applications

XMate Flexible Collaborative Robots are suitable for a variety of process applications, including flexible assembly, screw lock,inspection and measurement, transportation, removal of glue coating on materials, equipment care, etc.. It can help enterprises of all sizes to improve productivity and achieve flexible automation.

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Hot Searches