The

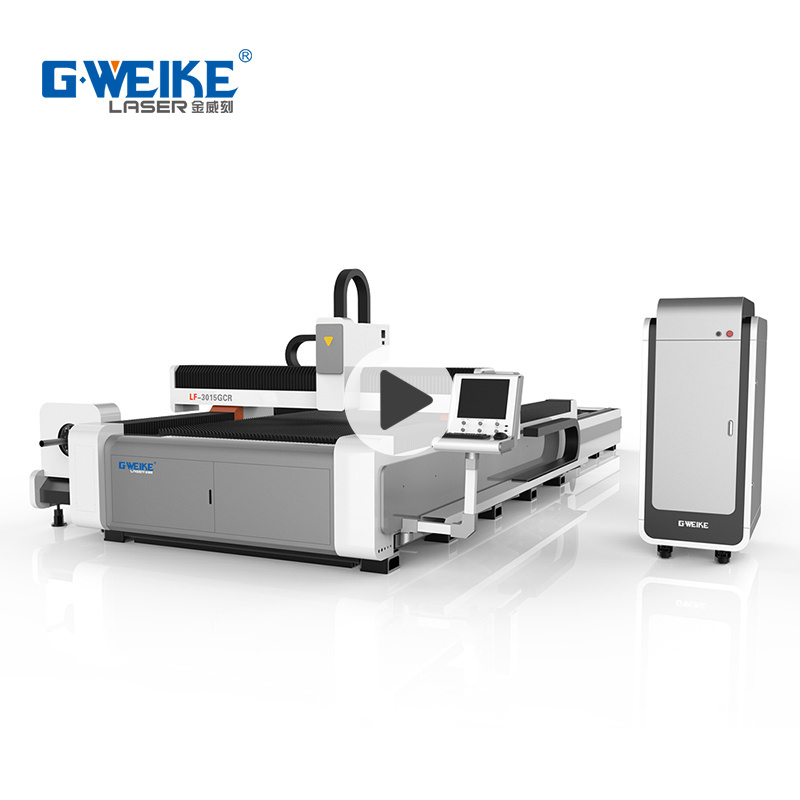

LF3015GCR

laser cutting machine is equipped with an electric chuck that automatically adjusts the center for stable tension. Tube fittings with different specifications and sizes are perfectly matched to meet complex production requirements. The quick response to formed tubes greatly improves cutting performance.

- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

Cypcut

-

Cutting Thickness:

-

0-20mm

-

Control Software:

-

CYPCUT

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Gweike

-

Weight (KG):

-

7300 KG

-

Core Components:

-

Laser source

-

Product name:

-

Fiber Laser Metal Cutting Machine

-

After-sales Service Provided:

-

Online Video Technical Support

-

Keyword:

-

Fiber Laser Cutting Machiens

-

Function:

-

Cutting Metal Materials

-

Laser power:

-

1000W /1500W/ 2000W / 3000W

-

Laser source:

-

IPG Raycus MAX

-

Working table:

-

Blade Table

-

Driving system:

-

Japan Yaskawa Servo Motor

-

Laser head:

-

Switzerland Raytools

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

0-120m/min

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

Cypcut

-

Cutting Thickness:

-

0-20mm

-

Control Software:

-

CYPCUT

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Gweike

-

Weight (KG):

-

7300 KG

-

Core Components:

-

Laser source

-

Product name:

-

Fiber Laser Metal Cutting Machine

-

After-sales Service Provided:

-

Online Video Technical Support

-

Keyword:

-

Fiber Laser Cutting Machiens

-

Function:

-

Cutting Metal Materials

-

Laser power:

-

1000W /1500W/ 2000W / 3000W

-

Laser source:

-

IPG Raycus MAX

-

Working table:

-

Blade Table

-

Driving system:

-

Japan Yaskawa Servo Motor

-

Laser head:

-

Switzerland Raytools

LF3015GCR Fiber Laser Cutting Machine

Machine Description

|

Machine Model

|

LF3015GCR LF4020GCR LF6025GCR

|

LF4020GA

|

LF6025GA

|

|

laser power

|

1000W 2000W 3000W 4000W 6000W 8000W(Optional)

|

|

|

|

Dimensions

|

7800*3580*2150mm 10050*4160*2160mm 14050*4657*2160mm

|

10750*3350*2310mm

|

15000*4018*2755mm

|

|

working area

|

3000mm x 1500mm 4000mm*2000mm 6000mm*2500mm

|

4000mm*2000mm

|

6000mm*2500mm

|

|

Repeat positioning accuracy

|

±0.02mm

|

|

|

|

Max speed

|

120m/min

|

|

|

|

Max acceleration

|

1.5G

|

|

|

|

Voltage and frequency

|

380V 50Hz/60Hz

|

|

|

Details Images

The software automatically adjusts the focusing lens to realize automatic perforating and cutting plates of different thickness.

The speed of automatically adjusting focus lens is ten times of the manual adjusting.

The speed of automatically adjusting focus lens is ten times of the manual adjusting.

Use the high definition toughened glass screen, more exquisite and delicate, the operation is smoother.

3rd Generation Aviation Aluminum Beam

It is manufactured with aerospace standards and formed by 4300 tons press extrusion molding. After aging treatment, its strength can reach 6061 T6 which is the strongest strength of all gantries. Aviation aluminum has many advantages, such as good toughness, light weight, corrosion resistance, anti-oxidation, low density, and greatly increase the processing speed.

Sample Display

Quality inspection

Packaging & Shipping

Hot Searches